Podcast

Questions and Answers

What is metal forming also known as?

What is metal forming also known as?

- Mechanical working of metals (correct)

- Metallurgical processing

- Thermal treatment of metals

- Mechanical cutting of metals

What is the main objective of metal working processes?

What is the main objective of metal working processes?

- To provide the desired shape and size, and to achieve optimum mechanical properties (correct)

- To improve the properties of the metal only

- To produce a new shape only

- To reduce the internal voids or cavities present

How can the necessary deformation in a metal be achieved?

How can the necessary deformation in a metal be achieved?

- By heating the metal only

- By application of mechanical force only or by heating the metal and then applying a small force (correct)

- By applying a high pressure only

- By applying a small force only

What happens to the impurities present in the metal during plastic deformation?

What happens to the impurities present in the metal during plastic deformation?

What is the condition required for plastic deformation of a metal to take place?

What is the condition required for plastic deformation of a metal to take place?

What occurs along two parallel planes in a metal during plastic deformation?

What occurs along two parallel planes in a metal during plastic deformation?

What is the ability of a material to be drawn into wire with the application of tensile force?

What is the ability of a material to be drawn into wire with the application of tensile force?

What is the process of making a metal harder and stronger through plastic deformation?

What is the process of making a metal harder and stronger through plastic deformation?

What is the result of dislocations interacting and becoming pinned or tangled in a metal?

What is the result of dislocations interacting and becoming pinned or tangled in a metal?

What is the temperature range at which strain hardening occurs?

What is the temperature range at which strain hardening occurs?

What occurs when strain hardened materials are exposed to elevated temperatures?

What occurs when strain hardened materials are exposed to elevated temperatures?

During heat treatment, what can occur to remove the effects of strain hardening?

During heat treatment, what can occur to remove the effects of strain hardening?

What is the result of the recovery phase during heat treatment?

What is the result of the recovery phase during heat treatment?

What is the result of recrystallization during heat treatment?

What is the result of recrystallization during heat treatment?

What is the result of grain growth during heat treatment?

What is the result of grain growth during heat treatment?

What is the primary advantage of hot rolling?

What is the primary advantage of hot rolling?

What happens to defects in the metal during hot working?

What happens to defects in the metal during hot working?

What is the main disadvantage of cold working?

What is the main disadvantage of cold working?

Why is it possible to hot work brittle materials?

Why is it possible to hot work brittle materials?

What is the result of hot rolling on the material's surface?

What is the result of hot rolling on the material's surface?

What is a major disadvantage of hot working?

What is a major disadvantage of hot working?

What is the primary purpose of rolling?

What is the primary purpose of rolling?

What is the primary purpose of cold working?

What is the primary purpose of cold working?

What is the result of strain hardening in cold working?

What is the result of strain hardening in cold working?

What is a limitation of cold working?

What is a limitation of cold working?

What is the main purpose of bending in sheet metal manufacturing?

What is the main purpose of bending in sheet metal manufacturing?

What is the result of hot working on the grain structure of cast metal?

What is the result of hot working on the grain structure of cast metal?

Why is hot working preferred over cold working in certain situations?

Why is hot working preferred over cold working in certain situations?

What is the result of grain growth in hot working?

What is the result of grain growth in hot working?

What is the main advantage of using hot working over cold working?

What is the main advantage of using hot working over cold working?

What is the minimum cross-sectional area of a bloom?

What is the minimum cross-sectional area of a bloom?

What is the minimum width of a slab?

What is the minimum width of a slab?

What is the minimum cross-sectional area of a billet?

What is the minimum cross-sectional area of a billet?

What is the minimum thickness of a plate?

What is the minimum thickness of a plate?

What is the characteristic of a strip?

What is the characteristic of a strip?

What is the characteristic of a two high reversing mill?

What is the characteristic of a two high reversing mill?

What is the advantage of a three high rolling mill?

What is the advantage of a three high rolling mill?

What is the purpose of mechanically operated lifted tables in a three high rolling mill?

What is the purpose of mechanically operated lifted tables in a three high rolling mill?

What type of rolling mill is used for hot rolling of armor and other plates?

What type of rolling mill is used for hot rolling of armor and other plates?

What is the purpose of a tandem rolling mill?

What is the purpose of a tandem rolling mill?

Flashcards are hidden until you start studying

Study Notes

Metal Forming

- Metal forming operations are used to produce a new shape or improve the properties of a metal.

- Shaping in the solid state can be divided into non-cutting shaping (e.g., forging, rolling, pressing) and cutting shaping (e.g., machining operations).

Plastic Deformation

- Plastic deformation occurs when a metal is deformed beyond its elastic range.

- The main objectives of metal working processes are to provide the desired shape and size, improve mechanical properties, and reduce internal voids or cavities.

- Metals are commonly worked by plastic deformation, which can be achieved by applying mechanical force or heating the metal and then applying a small force.

Strain Hardening

- Strain hardening (also known as work-hardening or cold-working) is the process of making a metal harder and stronger through plastic deformation.

- Dislocations move and interact with each other, resulting in a decrease in their mobility and a strengthening of the material.

- Strain hardening can be demonstrated by bending a wire or paper clip repeatedly.

Effects of Elevated Temperature on Strain Hardened Materials

- When strain hardened materials are exposed to elevated temperatures, the strengthening that resulted from the plastic deformation can be lost.

- Heat treatment can be used to remove the effects of strain hardening, which involves three stages: recovery, recrystallization, and grain growth.

Recovery

- Recovery occurs when a stain hardened material is held at an elevated temperature, allowing atoms to move to unstrained positions and relieve internal strain energy.

- This results in a reduction in internal residual stresses and a movement of dislocations to lower-energy positions.

Recrystallization

- Recrystallization occurs at a higher temperature, where new, strain-free grains nucleate and grow inside the old distorted grains and at the grain boundaries.

- This results in a return to the original weaker and more ductile states of the material.

Grain Growth

- Grain growth occurs when a specimen is left at a high temperature beyond the time needed for complete recrystallization.

- This results in a decrease in the strength and toughness of the material.

Embossing

- Embossing is a process that involves stretching a metal sheet to shape under pressure using a punch and a die.

- This process gives a stiffening effect to the metal and can produce ornamental wares.

Coining

- Coining is a cold working operation that involves producing shallow configurations on a metal surface using a die and a punch.

- This process is used for producing important articles such as medals, coins, and stickers.

Bending

- Bending is a common process in the manufacturing industry that involves the plastic deformation of a metal sheet over an axis.

- This process changes the shape of the workpiece while maintaining its volume.

Hot Working

- Hot working is a mechanical working process that occurs above the recrystallization temperature of the metal.

- This process is used to produce large deformations and can result in a refined grain structure and improved mechanical properties.

Effects of Hot Working on Mechanical Properties of Metals

- Hot working can produce a refined grain structure and improve mechanical properties.

- It can also reduce the stresses required to produce deformations and increase the possible amount of deformation.

- Hot working can result in a uniform distribution of impurities and improve the surface finish of the metal.

Merits of Hot Working

- Hot working can be used to achieve large deformations without strain hardening.

- It can improve the grain structure and mechanical properties of the metal.

- It can also reduce the stresses required to produce deformations.

Demerits of Hot Working

- Hot working can result in a poor surface finish due to oxidation and scaling.

- It can also lead to a loss of carbon from the surface of the steel, resulting in a loss of strength.

Cold Working

- Cold working is a mechanical working process that occurs below the recrystallization temperature of the metal.

- It is used to obtain better surface finish, increase mechanical properties, and produce thinner materials.

Purpose of Cold Working

- Cold working is used to obtain better surface finish and increase mechanical properties.

- It is also used to produce thinner materials and improve the dimensional accuracy of parts.

Limitations of Cold Working

- Cold working can result in a decrease in ductility and an increase in strain hardening.

- It requires higher forces and more powerful equipment than hot working.

- It can also result in a distortion of the grain structure and the formation of internal stresses.

Advantages of Cold Working

- Cold working can produce a smooth surface finish and accurate dimensions.

- It can increase the strength and hardness of the material.

- It can also result in better dimensional accuracy and a reduction in distortion.

Disadvantages of Cold Working

- Cold working can result in a distortion of the grain structure and the formation of internal stresses.

- It can also limit the amount of deformation that can be given to the material.

- It requires higher forces and more powerful equipment than hot working.

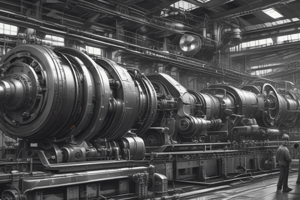

Rolling

- Rolling is a metal forming operation that involves the plastic deformation of a material caused by compressive force applied through a set of rolls.

- It is used to produce a wide range of products, including blooms, billets, plates, and sheets.

- Rolling can be done at high or low temperatures, depending on the desired outcome.### Rolling Process

- Hot rolling produces residual stress-free products, but scaling is a major problem, affecting dimensional accuracy.

- Cold rolling is gaining importance for sheets, foils, etc., due to high accuracy and lack of oxide scaling, and also strengthens the product through work hardening.

Rolling Mills

- Rolling is a major manufacturing process for sheets and other cross-sections of large length, such as I beams, railroads, etc.

- It involves compressing a metal workpiece between a set of rolls, reducing its cross-section area and increasing its length.

- This process offers high production rates, surface finish, and grain structure, but has high setup costs.

Terminology

- Ingot: a cast metal with porosity and blowholes, soaked at 1200°C and rolled into blooms, billets, or slabs.

- Blooms: the first rolled product, made by rolling ingot at high temperature, with a cross-section area ≥ 230 cm².

- Slab: made by hot rolling of ingot, with a cross-section area ≥ 100 cm² and width ≥ 3 times its thickness.

- Billets: made by hot rolling of blooms, with a cross-section area ≥ 40 cm², used to roll into pipes, bars, wire, etc.

- Plate: a product of further rolling of slab, with a thickness > 6 mm.

- Sheet: a product with a thickness < 6 mm and width > 60 cm.

- Strip: a product with a thickness < 6 mm and width < 60 cm.

Types of Rolling Mills

- Two high reversing mill: rolls rotate in one direction and then in the other, allowing the metal to pass back and forth through the rolls several times.

- Two high non-reversing mill: rolls revolve continuously in one direction, requiring smaller and less costly motive power.

- Three high rolling mill: consists of three parallel rolls, with adjacent rolls rotating in opposite directions, reducing thickness at each pass.

- Four high rolling mill: used for hot rolling of armor and other plates, as well as cold rolling of plates, sheets, and strips.

- Tandem rolling mills: used for rolling multiple stands in a continuous process.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.