Podcast

Questions and Answers

What is casting and why is it considered one of the oldest manufacturing processes?

What is casting and why is it considered one of the oldest manufacturing processes?

Casting is the process of pouring liquid material into a prepared mould cavity and allowing it to solidify. It is considered one of the oldest manufacturing processes because it is the first step in making most products.

What are the steps involved in metal casting?

What are the steps involved in metal casting?

The steps in metal casting include making the mould cavity, melting the material, pouring the liquid into the mould cavity, allowing it to solidify, and then cleaning and inspecting the product.

What are the advantages of casting as a manufacturing process?

What are the advantages of casting as a manufacturing process?

Casting allows molten material to flow into intricate shapes, minimizes the need for additional operations like machining, forging, and welding, and can be used for practically any material. The tools required for casting moulds are simple and inexpensive, making it ideal for small lot production.

What is the significance of pouring and solidification in the metal casting process?

What is the significance of pouring and solidification in the metal casting process?

Why is casting considered suitable for the production of small lots?

Why is casting considered suitable for the production of small lots?

What is the first step in making most products in metal casting?

What is the first step in making most products in metal casting?

What is the advantage of casting in terms of shaping intricate shapes?

What is the advantage of casting in terms of shaping intricate shapes?

What is the advantage of casting in terms of minimizing other operations like machining, forging, and welding?

What is the advantage of casting in terms of minimizing other operations like machining, forging, and welding?

What types of materials can be cast using the metal casting process?

What types of materials can be cast using the metal casting process?

What are the advantages of the necessary tools required for casting moulds?

What are the advantages of the necessary tools required for casting moulds?

Study Notes

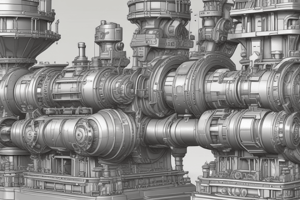

Metal Casting Process

- Metal casting is one of the oldest manufacturing processes and is the first step in making most products.

Steps in Metal Casting

- Creation of a mould cavity

- Melting of material in a suitable furnace to liquefy it

- Pouring of the liquid into a prepared mould cavity and allowing it to solidify

- Cleaning and inspection of the product, including trimming and shaping

Advantages of Casting

- Enables creation of intricate shapes by flowing into small sections

- Minimizes the need for additional operations like machining, forging, and welding

- Can be used to cast practically any material, including ferrous and non-ferrous metals

- Requires simple and inexpensive tools, making it ideal for small-scale production

- Suitable for producing complex parts, such as turbine blades

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Description

Test your knowledge of metal casting processes with this quiz on casting and foundry module. Learn about the steps involved in metal casting, including making mould cavities, melting materials, pouring and solidification. Perfect for students and professionals in manufacturing and engineering.