Podcast

Questions and Answers

What is the primary goal of Non-Destructive Examination (NDE) in material testing?

What is the primary goal of Non-Destructive Examination (NDE) in material testing?

- To test the material without damaging it (correct)

- To only test non-ferrous materials

- To test materials under high pressure

- To destroy the material to test its strength

Which ASME section provides a reference code for Non-Destructive Examination?

Which ASME section provides a reference code for Non-Destructive Examination?

- ASME Section X

- ASME Section VIII (Div. 1)

- ASME Section I

- ASME Section V (correct)

What type of materials are primarily used in power plant construction?

What type of materials are primarily used in power plant construction?

- Ferrous materials (correct)

- Non-ferrous materials

- Copper-based alloys

- Tin-based alloys

What is the purpose of the tests covered in this module?

What is the purpose of the tests covered in this module?

Why is it important to precisely define key terms in NDE?

Why is it important to precisely define key terms in NDE?

What is a flaw in the context of NDE?

What is a flaw in the context of NDE?

What is the primary purpose of evaluation in NDE?

What is the primary purpose of evaluation in NDE?

What is the benefit of NDE in terms of cost savings?

What is the benefit of NDE in terms of cost savings?

What type of defect is created during the initial production of the material?

What type of defect is created during the initial production of the material?

What is the benefit of NDE in terms of material verification?

What is the benefit of NDE in terms of material verification?

Flashcards are hidden until you start studying

Study Notes

Non-Destructive Examination (NDE)

- NDE is the testing of materials without destroying the integrity of the material or lowering its ability to perform its primary function.

NDE Techniques

- The most common NDE techniques used in the pressure equipment industry are:

- Hardness Testing

- Visual Testing (VT)

- Liquid Penetrant Testing (PT)

- Magnetic Particle Testing (MT)

- Radiographic Testing (RT)

- Ultrasonic Testing (UT)

- Acoustic Emission (AE)

- Leak Testing (LT)

Reference Code

- ASME Section V, Non-destructive Examination is a reference code that supports construction codes such as ASME Section I, III, IV, VIII (Div. 1 and Div. 2) and X.

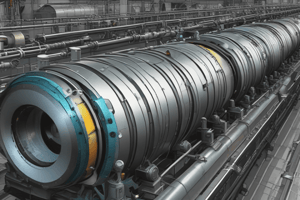

Materials Used in Power Plant Construction

- Non-ferrous materials are used in power plant construction, such as copper-based alloys for condenser tubing and copper for alternator windings.

- The majority of components are made from iron-based or ferrous materials.

Testing Definitions

- Flaw: An imperfection in the material that may or may not be harmful.

- Indication: A noticeable response to an NDE test that requires interpretation to determine its significance.

- Discontinuity: Any local variation in material continuity, including changes in geometry, properties, or composition, holes, cavities, cracks, or structure.

- Defect: A discontinuity or flaw, whose size, shape, type, location, or orientation creates a substantial chance of material failure.

- Interpretation: A study to determine the cause of an indication (labeling or naming the discontinuity).

- Evaluation: A judgment made based on codes, standards, or engineering assessment on the significance of an indication.

NDE Applications

- NDE techniques are used for testing materials for three types of defects:

- Inherent defects created during the initial production of the material

- Processing defects created during the processing/manufacturing of the pressure equipment

- Service defects created in the equipment during service

Benefits of NDE

- Safety: Prevent accidents, damage to property, injuries, and loss of life.

- Cost Savings: Eliminating faulty raw material reduces scrap, manpower required for rework, and prevents waste.

- Service Reliability: Faults can be sized for critical engineering assessment, and the remaining life span of used equipment can be estimated.

- Material Verification: Differences in chemical and metallurgical properties can be identified, and material can be identified for sorting.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.