Podcast

Questions and Answers

What is the primary function of material removal processes?

What is the primary function of material removal processes?

- To change the chemical properties of the material

- To deform the material without cutting

- To achieve the desired final geometry by removing excess material (correct)

- To add material to a work-part

Which of the following is NOT a principal machining process?

Which of the following is NOT a principal machining process?

- Milling

- Welding (correct)

- Turning

- Drilling

Which of the following statements about machining is TRUE?

Which of the following statements about machining is TRUE?

- Machining is only suitable for soft materials.

- Machining allows for high dimensional accuracy. (correct)

- Machining typically provides poor surface finishes.

- Machining is an additive manufacturing process.

What is a disadvantage of machining processes?

What is a disadvantage of machining processes?

What is a characteristic of a single-point cutting tool?

What is a characteristic of a single-point cutting tool?

What must be true about the material of a cutting tool compared to the work material?

What must be true about the material of a cutting tool compared to the work material?

Which of the following processes is typically performed after casting or bulk deformation?

Which of the following processes is typically performed after casting or bulk deformation?

What does the term 'nose radius' refer to in the context of a cutting tool?

What does the term 'nose radius' refer to in the context of a cutting tool?

What is a key characteristic of multi-point cutting tools?

What is a key characteristic of multi-point cutting tools?

Which of the following tools is classified as a multi-point cutting tool?

Which of the following tools is classified as a multi-point cutting tool?

Which part of a single point cutting tool is responsible for chip formation?

Which part of a single point cutting tool is responsible for chip formation?

In which application are multi-point cutting tools like helical milling cutters commonly used?

In which application are multi-point cutting tools like helical milling cutters commonly used?

What distinguishes single point cutting tools from multi-point cutting tools?

What distinguishes single point cutting tools from multi-point cutting tools?

What is the primary purpose of the end cutting edge in a single point cutting tool?

What is the primary purpose of the end cutting edge in a single point cutting tool?

Which of the following statements about the side flank of a single point cutting tool is accurate?

Which of the following statements about the side flank of a single point cutting tool is accurate?

Which of the following operations typically uses single point cutting tools?

Which of the following operations typically uses single point cutting tools?

What is the function of the flank face in machining tools?

What is the function of the flank face in machining tools?

Which angle is formed between the flank and rake faces?

Which angle is formed between the flank and rake faces?

What is the purpose of the cutting edge in a tool?

What is the purpose of the cutting edge in a tool?

Which cutting tool angle may vary from 5° to 30°?

Which cutting tool angle may vary from 5° to 30°?

What can happen if the side cutting edge angle is too large?

What can happen if the side cutting edge angle is too large?

What is the part of the tool that forms the corner between the side and end cutting edges called?

What is the part of the tool that forms the corner between the side and end cutting edges called?

Which component of a tool is defined as the part that is held?

Which component of a tool is defined as the part that is held?

What does the cutting wedge refer to in machining tools?

What does the cutting wedge refer to in machining tools?

What is the typical range for the side relief (clearance) angle (βs)?

What is the typical range for the side relief (clearance) angle (βs)?

Which angle is defined as the angle between the side flank and the rake face?

Which angle is defined as the angle between the side flank and the rake face?

What does a tool signature indicate?

What does a tool signature indicate?

For general-purpose tool bits, what is the typical value for the side rake angle (αs)?

For general-purpose tool bits, what is the typical value for the side rake angle (αs)?

Which element in the tool signature indicates the end relief angle?

Which element in the tool signature indicates the end relief angle?

What happens if the side rake angle is too negative?

What happens if the side rake angle is too negative?

Which of the following is NOT included in the seven elements of a tool signature?

Which of the following is NOT included in the seven elements of a tool signature?

How is the side flake angle defined in relation to tool design?

How is the side flake angle defined in relation to tool design?

What is the purpose of the end relief (clearance) angle (βe) on a cutting tool?

What is the purpose of the end relief (clearance) angle (βe) on a cutting tool?

What is typically true about the back rake angle (αb) on cutting tools?

What is typically true about the back rake angle (αb) on cutting tools?

Which statement correctly describes positive rake angles?

Which statement correctly describes positive rake angles?

What unique characteristic does high-speed steel (HSS) cutting tools have regarding rake angles?

What unique characteristic does high-speed steel (HSS) cutting tools have regarding rake angles?

What is the effect of a positive rake angle on the sharpness of a cutting tool?

What is the effect of a positive rake angle on the sharpness of a cutting tool?

What is true about the chip flow when using positive rake angles?

What is true about the chip flow when using positive rake angles?

How does the back rake angle influence the formation of a built-up edge?

How does the back rake angle influence the formation of a built-up edge?

What is the end wedge angle (γe) of a cutting tool defined as?

What is the end wedge angle (γe) of a cutting tool defined as?

Flashcards are hidden until you start studying

Study Notes

Material Removal Processes

- Material removal processes are a family of shaping operations

- The most popular branch of material removal processes is conventional machining

- Conventional machining involves using a sharp cutting tool to shape the material mechanically

- The three most prominent machining processes include turning, drilling, and milling

Advantages of Machining

- A wide variety of work materials can be machined

- Machining allows for a variety of part shapes and geometric features

- High dimensional accuracy can be achieved

- Good surface finishes are possible

Disadvantages of Machining

- Wasteful of material

- Time-consuming

Cutting Tools

- A cutting tool possesses one or more sharp cutting edges

- The cutting tool is made of a material that is harder than the work material

- The cutting edge separates a chip from the parent work material

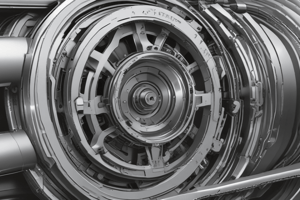

Single Point Cutting Tools

- Single point cutting tools have one cutting edge and used for operations like turning

- The point of the tool penetrates below the original work surface of the part

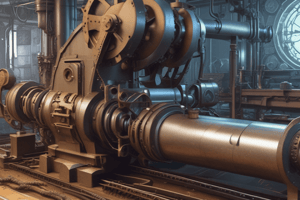

Multi-Point Cutting Tools

- Multi-point cutting tools have more than one cutting edge

- Multi-point cutting tools can be used for operations like drilling and milling

- Most multi-point cutting tools have a rotating motion

Cutting Tool Angles

- The side cutting angles may vary from 10° to 20°

- The end cutting edge angle can range from 5° to 30°

- The nose radius is the rounded end of the tool bit

- The end relief (clearance) angle permits the cutting tool to be fed into the work

- The top rake angle is the backward slope of the tool face away from the nose

Tool Signature

- Tool signature, also known as tool nomenclature, specifies tool angles using a standardized abbreviated system

- A tool signature indicates the angles that a tool utilizes during the cut

- The seven elements of a single point cutting tool signature can be stated in this order: back rake angle, side rake angle, end relief angle, side relief angle, end cutting edge angle, side cutting edge angle, and nose radius.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.