Podcast

Questions and Answers

How can the upper bearing components be removed from the piston tube?

How can the upper bearing components be removed from the piston tube?

- Push out the upper bearing retaining pins (correct)

- Remove the bolt at the top of the strut housing

- Unscrew the snap ring at the bottom of the tube

- Slide the outer and inner 'O' rings from the tube

What is the correct procedure to remove the orifice plate from the orifice tube?

What is the correct procedure to remove the orifice plate from the orifice tube?

- Pull out the snap ring at the top of the fork

- Unscrew the bolt at the top of the fork

- Release the snap ring at the bottom of the orifice tube (correct)

- Push out the orifice plate from the top of the strut housing

How can one remove the piston tube plug located at the lower end of the tube?

How can one remove the piston tube plug located at the lower end of the tube?

- Remove the bolt assembly at the top of the fork and push a rod up through the hole in the body of the fork (correct)

- Slide out the washer and snap ring from the tube

- Push out the plug from the bottom of the tube

- Unscrew the bolt at the top of the strut housing

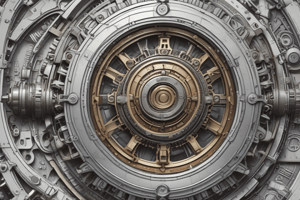

What component should be secured with the snap ring (22) during the assembly of the orifice tube?

What component should be secured with the snap ring (22) during the assembly of the orifice tube?

Where should the 'O' ring (19) be installed during the assembly process?

Where should the 'O' ring (19) be installed during the assembly process?

Which part of the fork tube assembly should have outer and inner 'O' rings (9 and 11)?

Which part of the fork tube assembly should have outer and inner 'O' rings (9 and 11)?

Flashcards are hidden until you start studying

Study Notes

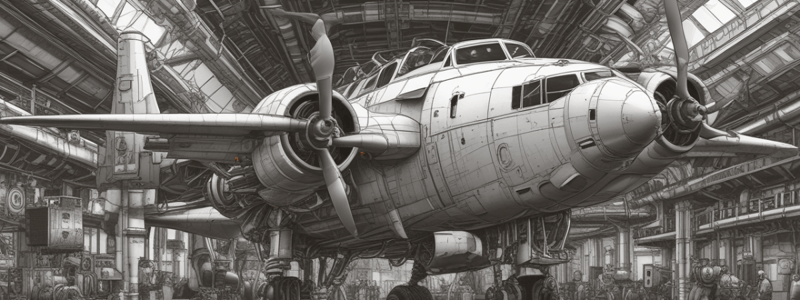

Main Gear Assembly

- Adjust doors one at a time, ensuring no load is exerted on the cylinder, and retraction rods pass freely through their holes.

- Extend the landing gear, connect both doors, and retract the landing gear fully to ensure a 0.31-inch gap between the doors.

- Take up each retraction rod two additional turns to pre-load the doors.

Disassembly of Main Gear Oleo

- The main gear oleo assembly can be removed and disassembled from the gear oleo housing with the gear removed from or installed on the airplane.

- Place the airplane on jacks and a drip pan under the main gear to catch spillage.

- Remove air and fluid from the oleo strut by depressing the air valve core pin, removing the air charge valve, and siphoning out hydraulic fluid.

- Disconnect the brake hydraulic lines above the bracket on the main gear fork assembly.

- Remove the torque link assembly by removing the cotter pin, nut, washer, and bolt from the strut housing and fork assembly.

Removing Components

- Remove the piston tube components by pushing out the upper bearing retaining pins.

- Remove the upper bearing, spacer, lower bearing, "O" rings, and wiper strip from the tube.

- Remove the orifice tube by removing the bolt and washer from the top of the strut housing.

- Remove the orifice plate from the bottom of the orifice tube by releasing the snap ring.

- Remove the piston tube plug with "O" ring by removing the bolt assembly and inserting a rod up through the fork.

Inspection and Repair

- Inspect components for corrosion, scratches, nicks, and excess wear.

- Repair is limited to smoothing out minor scratches, nicks, and dents, and replacing parts.

- Service tolerance for wear of components can be found in Table VII-III.

Assembly of Main Gear Oleo

- Ensure parts are clean and inspected before assembly.

- Press the tube end into the fork body, aligning the bolt holes, and drill a pilot hole if necessary.

- Install the piston tube plug with "O" ring, lubricating the tube and plug with hydraulic fluid.

- Assemble the orifice tube by inserting the orifice plate and securing it with a snap ring.

- Install the tube into the strut housing, with the packing, washer, and bolt.

- Assemble the fork tube by installing the tube components in the correct order.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.