Podcast

Questions and Answers

What is the primary function of the worktable in a grinding machine?

What is the primary function of the worktable in a grinding machine?

- To move the grinding wheel

- To apply pressure to the workpiece

- To support and locate the workpiece (correct)

- To rotate the workpiece

Which type of abrasive is commonly used for grinding hardened steel?

Which type of abrasive is commonly used for grinding hardened steel?

- Silicon carbide

- Alumina

- Cubic boron nitride (correct)

- Ceramic alumina

What is the primary advantage of centerless grinding over other grinding methods?

What is the primary advantage of centerless grinding over other grinding methods?

- Reduced grinding wheel wear

- No need for workpiece centering (correct)

- Increased precision

- Improved surface finish

What is the primary factor in selecting a grinding wheel for a specific grinding operation?

What is the primary factor in selecting a grinding wheel for a specific grinding operation?

What is the primary characteristic of a grinding wheel that affects its cutting action?

What is the primary characteristic of a grinding wheel that affects its cutting action?

Which type of cylindrical grinding is used to grind the internal diameter of a bearing component?

Which type of cylindrical grinding is used to grind the internal diameter of a bearing component?

What is the primary purpose of the tailstock in a cylindrical grinding machine?

What is the primary purpose of the tailstock in a cylindrical grinding machine?

Which grinding operation is used to grind a tapered surface on a shaft?

Which grinding operation is used to grind a tapered surface on a shaft?

Flashcards are hidden until you start studying

Study Notes

Grinding Machines

- Types:

- Surface grinders

- Cylindrical grinders

- Centerless grinders

- Tool and cutter grinders

- Special purpose grinders

- Components:

- Grinding wheel

- Worktable

- Spindle

- Tailstock

- Cross-feed

- Operations:

- Traverse grinding

- Plunge grinding

- Angular grinding

Abrasive Grinding

- Definition: Grinding process using an abrasive material to remove material from a workpiece

- Types of abrasives:

- Alumina (Al2O3)

- Silicon carbide (SiC)

- Ceramic alumina (Al2O3 + additives)

- Diamond

- Cubic boron nitride (cBN)

- Characteristics:

- Hardness

- Grain size

- Bond type (vitrified, resinoid, metal)

- Porosity

Centerless Grinding

- Definition: Grinding process where the workpiece is supported by a work rest and rotated between two wheels

- Types:

- Through-feed grinding

- In-feed grinding

- End-feed grinding

- Advantages:

- High precision

- High productivity

- No need for workpiece centering

- Applications:

- Bearing components

- Shafts

- Axles

Grinding Wheels

- Definition: Abrasive tool used for grinding operations

- Components:

- Abrasive grains

- Bonding material

- Filler material

- Characteristics:

- Grain size

- Bond type

- Porosity

- Wheel speed

- Selection criteria:

- Workpiece material

- Grinding operation

- Wheel speed

- Coolant used

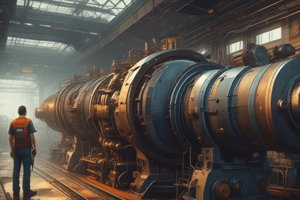

Cylindrical Grinding

- Definition: Grinding process where the workpiece is rotated and moved longitudinally between two wheels

- Types:

- External cylindrical grinding

- Internal cylindrical grinding

- Operations:

- Traverse grinding

- Plunge grinding

- Taper grinding

- Applications:

- Axles

- Shafts

- Gears

- Bearing components

Grinding Machines

- Grinding machines types include surface grinders, cylindrical grinders, centerless grinders, tool and cutter grinders, and special purpose grinders

- Main components of grinding machines are grinding wheel, worktable, spindle, tailstock, and cross-feed

- Grinding machines perform traverse grinding, plunge grinding, and angular grinding operations

Abrasive Grinding

- Abrasive grinding is a process that uses an abrasive material to remove material from a workpiece

- Types of abrasives used in grinding are alumina, silicon carbide, ceramic alumina, diamond, and cubic boron nitride

- Characteristics of abrasives include hardness, grain size, bond type, and porosity

Centerless Grinding

- Centerless grinding is a process where the workpiece is supported by a work rest and rotated between two wheels

- Types of centerless grinding are through-feed grinding, in-feed grinding, and end-feed grinding

- Centerless grinding offers high precision, high productivity, and eliminates the need for workpiece centering

- Centerless grinding is commonly used for bearing components, shafts, and axles

Grinding Wheels

- Grinding wheels are abrasive tools used for grinding operations

- Grinding wheel components include abrasive grains, bonding material, and filler material

- Characteristics of grinding wheels include grain size, bond type, porosity, and wheel speed

- Selection of grinding wheels depends on workpiece material, grinding operation, wheel speed, and coolant used

Cylindrical Grinding

- Cylindrical grinding is a process where the workpiece is rotated and moved longitudinally between two wheels

- Types of cylindrical grinding include external cylindrical grinding and internal cylindrical grinding

- Cylindrical grinding operations include traverse grinding, plunge grinding, and taper grinding

- Cylindrical grinding is commonly used for axles, shafts, gears, and bearing components

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.