Podcast

Questions and Answers

List three essential conditions that should be met for effective metal cutting, focusing on the properties of the tool and the applied forces.

List three essential conditions that should be met for effective metal cutting, focusing on the properties of the tool and the applied forces.

The tool material should be harder than the workpiece, the cutting force applied should exceed the workpiece's strength, and the tool geometry should facilitate efficient chip formation and cutting action.

Explain the difference between orthogonal and oblique metal cutting processes based on the orientation of the cutting edge relative to the cutting direction.

Explain the difference between orthogonal and oblique metal cutting processes based on the orientation of the cutting edge relative to the cutting direction.

In orthogonal cutting, the tool's cutting edge is perpendicular (90°) to the cutting direction, resulting in a two-dimensional cutting action. In oblique cutting, the cutting edge is inclined at an angle less than 90° to the cutting direction, leading to a three-dimensional cutting process.

Describe the main difference between single-point and multi-point cutting tools and provide an example of each.

Describe the main difference between single-point and multi-point cutting tools and provide an example of each.

Single-point cutting tools have one cutting edge, such as those used in turning on a lathe. Multi-point cutting tools have multiple cutting edges, as seen in milling cutters or drills.

Explain what is meant by 'tool geometry' in the context of metal cutting and list three angles that define the geometry of single-point cutting tools.

Explain what is meant by 'tool geometry' in the context of metal cutting and list three angles that define the geometry of single-point cutting tools.

Describe the function of 'rake angle' in cutting tools and how positive, zero, and negative rake angles affect cutting performance.

Describe the function of 'rake angle' in cutting tools and how positive, zero, and negative rake angles affect cutting performance.

List and briefly describe the three main types of chips produced during metal cutting.

List and briefly describe the three main types of chips produced during metal cutting.

In the context of metal cutting, what do the terms 'Shear Angle' and 'Rake Angle' refer to, and how do they influence the cutting process?

In the context of metal cutting, what do the terms 'Shear Angle' and 'Rake Angle' refer to, and how do they influence the cutting process?

Describe the purpose of using American Standard Association (ASA) tool designation system in machining.

Describe the purpose of using American Standard Association (ASA) tool designation system in machining.

Explain the key difference between ASA and ORS (Orthogonal Rake System) tool designation.

Explain the key difference between ASA and ORS (Orthogonal Rake System) tool designation.

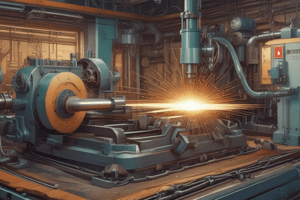

Describe the working principle of a lathe machine in terms of how it shapes a workpiece.

Describe the working principle of a lathe machine in terms of how it shapes a workpiece.

Classify lathe machines based on purpose of use, providing one example for each category.

Classify lathe machines based on purpose of use, providing one example for each category.

How does size or capacity classify lathe machines, and what are three common size classifications?

How does size or capacity classify lathe machines, and what are three common size classifications?

List three ways to classify lathe machines based on the configuration of the jobs being handled.

List three ways to classify lathe machines based on the configuration of the jobs being handled.

Describe two classifications of lathe machines based on their precision.

Describe two classifications of lathe machines based on their precision.

List two classifications of lathe machines based on the number of spindles they utilize.

List two classifications of lathe machines based on the number of spindles they utilize.

Name three classifications of lathe machines based on degree of automation.

Name three classifications of lathe machines based on degree of automation.

Describe three key specifications that define the capacity and capabilities of a lathe machine?

Describe three key specifications that define the capacity and capabilities of a lathe machine?

Name five main parts of a lathe machine.

Name five main parts of a lathe machine.

List three types of accessories used for mounting jobs in center lathes without tailstock support.

List three types of accessories used for mounting jobs in center lathes without tailstock support.

Name three common accessories used for mounting tools in Centre lathes.

Name three common accessories used for mounting tools in Centre lathes.

What are two types of tool mounting options used in automatic lathes?

What are two types of tool mounting options used in automatic lathes?

Identify five operations that can be performed on a lathe machine.

Identify five operations that can be performed on a lathe machine.

Explain the purpose of Cutting Speed, Feed, and Depth of Cut.

Explain the purpose of Cutting Speed, Feed, and Depth of Cut.

Describe the working principle of a drilling machine, explaining how it creates holes in a workpiece.

Describe the working principle of a drilling machine, explaining how it creates holes in a workpiece.

List two primary classifications of drilling machines.

List two primary classifications of drilling machines.

What are the key specifications considered when selecting a drilling machine?

What are the key specifications considered when selecting a drilling machine?

Describe the use of 'jigs' and 'fixtures' in drilling.

Describe the use of 'jigs' and 'fixtures' in drilling.

What are the most common types of 'tool' used in drilling?

What are the most common types of 'tool' used in drilling?

Operations on drilling machine?

Operations on drilling machine?

Distinguish between 'fixed automation' and 'flexible automation' and lathe machines.

Distinguish between 'fixed automation' and 'flexible automation' and lathe machines.

What is the main purpose of using cutting fluids in machining operations?

What is the main purpose of using cutting fluids in machining operations?

Describe machine's cutting process

Describe machine's cutting process

Describe the importance of specifying tool parameters?

Describe the importance of specifying tool parameters?

Classify cutting tools.

Classify cutting tools.

Describe classification according to construction.

Describe classification according to construction.

Flashcards

Cutting tool material

Cutting tool material

Material used for cutting should be harder than the workpiece.

Cutting force

Cutting force

The force applied must exceed the workpiece's strength to achieve cutting.

Cutting tool geometry

Cutting tool geometry

It includes rake angle, relief angle, and cutting edge geometry.

Orthogonal cutting process

Orthogonal cutting process

Signup and view all the flashcards

Orthogonal Cutting Edge

Orthogonal Cutting Edge

Signup and view all the flashcards

Oblique cutting process

Oblique cutting process

Signup and view all the flashcards

Oblique Cutting Edge

Oblique Cutting Edge

Signup and view all the flashcards

Single point cutting tool

Single point cutting tool

Signup and view all the flashcards

Multi point cutting tool

Multi point cutting tool

Signup and view all the flashcards

Solid tools

Solid tools

Signup and view all the flashcards

Tipped cutting tools

Tipped cutting tools

Signup and view all the flashcards

Rake angle

Rake angle

Signup and view all the flashcards

Positive Rake Angle Benefit

Positive Rake Angle Benefit

Signup and view all the flashcards

Zero Rake Angle Benefit

Zero Rake Angle Benefit

Signup and view all the flashcards

Negative Rake Angle Benefit

Negative Rake Angle Benefit

Signup and view all the flashcards

Relief / Clearance angle

Relief / Clearance angle

Signup and view all the flashcards

Continuous chips

Continuous chips

Signup and view all the flashcards

Discontinuous chips

Discontinuous chips

Signup and view all the flashcards

Built-up edge chips

Built-up edge chips

Signup and view all the flashcards

Cutting Speed (V)

Cutting Speed (V)

Signup and view all the flashcards

Feed (f)

Feed (f)

Signup and view all the flashcards

Depth of Cut (t)

Depth of Cut (t)

Signup and view all the flashcards

Lathe Machine Working

Lathe Machine Working

Signup and view all the flashcards

General Purpose Lathe

General Purpose Lathe

Signup and view all the flashcards

Single Purpose Lathe

Single Purpose Lathe

Signup and view all the flashcards

Special Purpose Lathe

Special Purpose Lathe

Signup and view all the flashcards

Small Lathe

Small Lathe

Signup and view all the flashcards

Medium Lathe

Medium Lathe

Signup and view all the flashcards

Large Lathe

Large Lathe

Signup and view all the flashcards

Mini Lathe

Mini Lathe

Signup and view all the flashcards

Drilling Machine Working

Drilling Machine Working

Signup and view all the flashcards

Drill Machine Specifications

Drill Machine Specifications

Signup and view all the flashcards

Drilling machine operations.

Drilling machine operations.

Signup and view all the flashcards

Study Notes

Fundamentals of Machining & Machining Operations

- Unit I focuses on the fundamentals of machining and machining operations.

- Course outcomes involve producing jobs using lathe and drilling machines.

- This unit accounts for 14 marks.

Mechanism of Metal Cutting

- Metal cutting conditions require the cutting tool material to be harder than the workpiece.

- Applied cutting force must exceed the workpiece strength.

- Cutting tool geometry is a key factor.

- Key angles in metal cutting include rake angle (µ), shear angle (f), and relief angle (r).

- An uncut chip has a thickness denoted as t, while the chip thickness after the cut is tc.

Types of Metal Cutting Processes

- Metal cutting processes can be categorized into orthogonal and oblique cutting.

Orthogonal Cutting Process

- Is a two-dimensional cutting process

- The tool cutting edge is at 90° to the line of action/path of the tool, and the cutting velocity vector.

- Cutting involves only two forces

- Is simpler to analyze.

Oblique Cutting Process

- Is a three-dimensional cutting process.

- The cutting edge is inclined at less than 90° to the line of action/path of the tool and cutting velocity vector.

- Analysis is more difficult compared to orthogonal cutting.

Types of Cutting Tools

- Cutting tools are classified based on the number of cutting points.

- Single point cutting tools exists

- Multi point cutting tools exists

- Tool construction determines whether they are solid or tipped.

Cutting Tool Geometry

- Aspects include the shank, face, flank, principal flank, auxiliary flank, rake angle, back rake angle, and side rake angle.

- Relief angle also is factor, including side and end relief angles

- Cutting angles include side and end cutting edge angles

- Tool nose radius is another factor

Cutting Tool Geometry - Rake Angle

- Rake angles ensure ease of chip flow during machining.

- A positive rake angle reduces cutting force and power requirements.

- A zero rake angle simplifies design and manufacturing.

- A negative rake angle increases edge-strength and tool life.

Cutting Tool Geometry - Relief / Clearance Angle

- Prevents rubbing between the tool (flank) and the machined surface.

Types of Chips

- Chips formed during cutting process are classified as continuous, discontinuous and built-up edge (BUE).

- Continuous chips are formed from ductile materials at high cutting speeds, fine feeds, with positive, large rake angle and cutting fluid

- Discontinuous chips are produced from brittle materials/ductile but hard with medium-high cutting speeds, large feeds, negative rake angle and cutting fluid is absent.

- Continuous with BUE chips are formed from ductile materials at low cutting velocity, medium/large feed, small/negative rake angle and cutting fluid is absent

Cutting Forces

- Several forces are involved in metal cutting: shear force at shear plane (Fs), normal force at shear plane (Fn), and the resultant force of Fs and Fn (R').

- Tangential force on the tool face (F).

- Normal force on the tool face acting on the chip (N).

- The resultant force of F and N is denoted as R

- Horizontal component of the cutting force (Fc).

- Vertical component or Thrust force (Ft).

- Shear stress on the shear plane (τs).

- Rake angle of the cutting tool (α).

- Coefficient of friction (µ).

- Angle of friction (ß).

- Shear Angle (Φ)

Force Expressions

- Shear force = Fs = Fc * cos(φ) - Ft * sin(φ).

- Normal force = Fn = Fc * sin(φ) + Ft * cos(φ)

- Tangential frictional force: F = Fc * sin(α) + Ft * cos(α)

- Normal force is expressed as: N = Fc * cos(α) - Ft * sin(α)

- Shear Angle can be found by φ =tan^-1( (r * cos α) / (1 -r sin α) )

- Coefficient of friction: μ = tan β = (Fc tan α + Ft) / (Fc - Ft tan α).

Cutting Tool Designation

- ASA (American Standard Association System) and ORS (Orthographic Rake System) are used

ASA Tool Designation

- Includes angles like side cutting edge angle (Cs), end cutting edge angle (Ce), side relief angle (Os), end relief angle (Oe), side rake angle (αs), & back rake angle (αb).

ORS Tool Designation

- Involves side relief angle (γ), side rake angle (α), wedge/lip angle (β), cutting angle (δ), back rake/inclination angle (i), end relief angle(γ1), end cutting edge angle (Ce).

Lathe Machine Fundamentals

- Working principle: The workpiece is held in a spindle-mounted chuck and turned against a cutting tool to remove material in the form of chips.

- Classification is based on configuration, purpose of use, size or capacity, and the configuration of jobs handled.

Classification by Configuration

- Horizontal lathes

- Vertical lathes

Classification by Purpose of Use

- General-purpose lathe machines handle all types of operations.

- Single-purpose serve one type of operation

- Special-purpose lathe machines repeat specific operations.

Classification by Size or Capacity

- Small/low duty handles small to medium jobs.

- Medium duty lathes are versatile and commonly used.

- Large/heavy duty lathes handle large jobs.

- Mico/mini handles small size precision work

Classification by Configuration of Jobs Handled

- Bar type lathe machines hold jobs in collets.

- Chuck type lathe machines hold jobs in chucks.

- Housing type lathe machines handle odd-shaped jobs on a face plate.

Classification by Precision

- Ordinary lathe are standard machines

- Precision lathe machines gives high accuracy

Classification by Number of Spindles

- Single spindle lathe machines standard single operation machines

- Multiple lathe operations does fast and mass production

Classification by Type of Automation

- Fixed automation lathe machines utilize conventional single spindle automats.

- Flexible automation lathe machines use modern CNC lathes and Turing centres.

Classification by Degree of Automation

- Non-automatic lathe machines are conventional.

- Semi-automatic lathe machines are copying lathes.

- Automatic lathe machines are single spindle automat.

Lathe Machine Specification

- Includes maximum job diameter and length.

- Power of the main drive

- Range of spindle speeds and feeds

- Space occupied by the machine.

Lathe Machine Parts

- Consists of a headstock, tailstock, bed, carriage, cross slide, compound rest, tool post, and lead screw.

Lathe Machine Accessories - Centre Style

- Mounting jobs in Centre lathes is done without additional tailstock support.

- Chucks (3-jaw self-centering, 4 independent jaw)

- Face plates

- Jigs and fixtures.

- With tailstock support includes

- In-between Centre

- In-between chuck and Centre

- In-between headstock and tailstock

Lathe Machine Accessories - CNC Style

- Coventry concentric chucks

- Air operated chucks,

- Quick acting soft jaw chucks

- Collet chucks

Lathe Machine Accessories - Tool Mounting

- HSS tools (shank type)

- HSS form and threading tools

- Carbide and ceramic inserts

- Drills and reamers

- Boring tools

Lathe Machine Accessories - Automatic Style

- Radial slides (front and rear)

- Turrets (mostly hexagonal) for tool mounting

Lathe Machine Operations

- Straight turning

- Taper turning

- Profiling

- Turning and external grooving

- Facing

- Face grooving

- Cutting with a form tool

- Boring and internal grooving

- Drilling

- Cutting off

- Threading

- Knurling

Lathe Machine Cutting Parameters

- Cutting Speed (V): Is the speed at which metal is removed, expressed in m/min or mm/min; calculated as V = πDN / 1000.

- Feed (f): Relative motion of the cutting tool in one workpiece revolution; expressed in mm/rev.

- Depth of Cut (t): The total metal removed per pass, expressed in mm, varies with tool type and material.

Drilling Machine Fundamentals

- Working principle involves producing holes by using a rotating cutter called a drill.

- The machine tool exerts vertical cutting force to create a hole.

Drilling Machine Classification

- Portable drilling machines, accommodating 12 to 18 mm drill sizes.

- Sensitive drilling machines, available as table top (0.5 kW, 10 mm) and floor mounting (1.5 to 15.5 mm).

- Upright drilling machines. Pillar (0.55 - 1.1 kW, 50 mm). Box column construction

Drilling Machine Classifications

- Gang drilling machines use 2 to 6 spindles with variable drills simultaneously.

- Multi-spindle are central with a planetary gear system using variable drills on a telescopic part

- Turret-type which is column type with a turret that holds no drills

Drilling Machine Specifications

- Specifications include the maximum drill size (diameter), hole size and taper in the spindle.

- Also the range of spindle speeds and feeds

- Power of the main drive

- Axial travel range of the spindle/bed

- Floor space occupied

Drilling Machine Accessories - Job Mounting

- Angle, drilling, and diameter jigs.

- Plate jibs

- Vices for clamping work

Drilling Machine Accessories - Tool Mounting

- Drill sleeves

- Drilling chucks

- Tapping tool mountings

Drilling Machine Operations

- Reaming

- Tapping

- Counter-boring

- Counter-sinking

- Centre drilling

- Spot facing

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.