Podcast

Questions and Answers

What is the primary reason why dull wheels are problematic?

What is the primary reason why dull wheels are problematic?

- They are more difficult to handle

- They produce less precise grinding

- They are more expensive to replace

- They require more pressure, leading to potential wheel explosion (correct)

What is the recommended maximum gap for the tool rest on a bench or pedestal grinder?

What is the recommended maximum gap for the tool rest on a bench or pedestal grinder?

- 1/2 inch

- 1/16 inch

- 1/8 inch (correct)

- 1/4 inch

What should you do when setting up a new wheel on a grinder?

What should you do when setting up a new wheel on a grinder?

- Check the electrical cables for damage after setting up the wheel

- Stand directly in front of the grinder when starting it up

- Position the wheel no more than 1/16 inch away from the wheel periphery (correct)

- Apply heavy pressure to test the wheel

What is the typical grit size of the wheel on the right-hand side of a bench mounted grinder?

What is the typical grit size of the wheel on the right-hand side of a bench mounted grinder?

Why should you stand to one side of the grinder upon start-up?

Why should you stand to one side of the grinder upon start-up?

What should be checked for damage before using a grinder?

What should be checked for damage before using a grinder?

Why should you apply gradual pressure when using a grinder?

Why should you apply gradual pressure when using a grinder?

What is the typical diameter of the wheel on a bench mounted grinder?

What is the typical diameter of the wheel on a bench mounted grinder?

What is the average RPM of a common wheel?

What is the average RPM of a common wheel?

What is the primary use of a pedestal grinder?

What is the primary use of a pedestal grinder?

What is the advantage of using a side grinder?

What is the advantage of using a side grinder?

What is the purpose of coarse grit wheels?

What is the purpose of coarse grit wheels?

What type of wheel is used to grind non-ferrous materials?

What type of wheel is used to grind non-ferrous materials?

What is the consequence of grinding non-ferrous material on an Aluminum Oxide Grinding Wheel?

What is the consequence of grinding non-ferrous material on an Aluminum Oxide Grinding Wheel?

What is the characteristic of a fine grit wheel?

What is the characteristic of a fine grit wheel?

What is the diameter range of a pedestal grinder wheel?

What is the diameter range of a pedestal grinder wheel?

What is the primary factor that determines the hardness of a grinding wheel?

What is the primary factor that determines the hardness of a grinding wheel?

What is the advantage of using a soft-bonded grinding wheel?

What is the advantage of using a soft-bonded grinding wheel?

What should be done before turning on the grinder after installing a new wheel?

What should be done before turning on the grinder after installing a new wheel?

What is the purpose of a wheel blotter?

What is the purpose of a wheel blotter?

Why is it necessary to perform a ring test on new wheels?

Why is it necessary to perform a ring test on new wheels?

What type of thread is used on the right side of the grinder?

What type of thread is used on the right side of the grinder?

What is the result of using a hard-bonded grinding wheel?

What is the result of using a hard-bonded grinding wheel?

What should be checked before installing a new wheel on the grinder?

What should be checked before installing a new wheel on the grinder?

What is the result of a loaded grinding wheel?

What is the result of a loaded grinding wheel?

Why is wheel dressing necessary?

Why is wheel dressing necessary?

When should wheel dressing be performed?

When should wheel dressing be performed?

What is the purpose of truing a grinding wheel?

What is the purpose of truing a grinding wheel?

What causes a grinding wheel to become loaded?

What causes a grinding wheel to become loaded?

What is used to true a grinding wheel?

What is used to true a grinding wheel?

What is the result of not truing a grinding wheel?

What is the result of not truing a grinding wheel?

What should be done after truing a grinding wheel?

What should be done after truing a grinding wheel?

What is the primary function of wheel flanges?

What is the primary function of wheel flanges?

What should be checked on the wheel flange during inspection?

What should be checked on the wheel flange during inspection?

What is the purpose of wheel bushings?

What is the purpose of wheel bushings?

What is the consequence of a glazed wheel?

What is the consequence of a glazed wheel?

Why should the initial tensioning of the wheel spindle not be overly tightened?

Why should the initial tensioning of the wheel spindle not be overly tightened?

What should be used to provide rotational locking during the tightening operation of the wheel spindle?

What should be used to provide rotational locking during the tightening operation of the wheel spindle?

Why should blotters be in place on both sides of the wheel?

Why should blotters be in place on both sides of the wheel?

What type of thread is used on the left-hand side of the spindle?

What type of thread is used on the left-hand side of the spindle?

Flashcards are hidden until you start studying

Study Notes

Safety Procedures

- Fasten pedestal and bench grinders securely to a solid surface to prevent movement during operation.

- Ensure all guards are in place and secure before using a grinder.

- Check electrical cables for damage from metal debris and sparks, and poor connections.

- Stand to one side of the grinder upon start-up and until the wheel reaches operating speed before engaging in work.

- Apply gradual pressure to allow the wheel to warm up evenly, as dull wheels can cause excessive pressure.

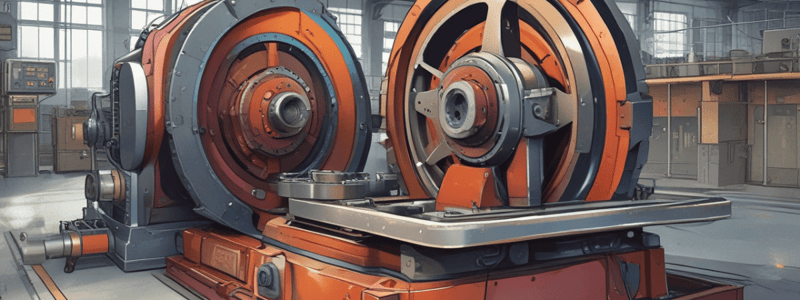

Grinder Safety

- The tool rest on any bench or pedestal grinder must not exceed 1/8” gap (OH&S).

- When setting up a new wheel, it should be no more than 1/16” away from the wheel periphery.

Grinder Types

- Bench Mounted Grinder:

- Typical wheel size: 6, 8, 10 inches in diameter.

- Wheel grits: coarse (60-80) on the left-hand side and fine (120-180) on the right-hand side.

- Common wheel width: 1 inch.

- Average RPM: 3600.

- Used for finish or general-purpose shop type applications.

- Pedestal Grinder:

- Wheel diameter: 10-24 inches.

- Wheel width: 1-3 inches.

- Maximum RPM: 1800.

- Used for snagging, removing large amounts of material, and rough grinding operations.

- Side Grinders:

- Designed to grind on the face of the wheel.

- Special wheels with steel backing plates are required.

- Advantage: tools can be sharpened on a flat face rather than the periphery of a round wheel.

Wheel Selection

- Grinding wheels are available in various grit sizes.

- Lower grit numbers (36-80) are used for roughing operations, while higher grit numbers (100-240) are used for finish operations.

- Wheel types:

- Aluminum Oxide Wheels: for ferrous materials, not for non-ferrous materials.

- Silicon Carbide Wheels: for non-ferrous materials, such as sharpening carbide cutting tools, brass, and bronze.

Wheel Mounting

- Wheel installation:

- Check for wheel appropriate blotters.

- Check the wheel fit.

- Tighten fasteners before turning the grinder on.

- Manually spin the wheel to ensure it spins freely.

- Wheel spindles:

- Left-hand thread on the left-hand side of the spindle.

- Right-hand thread on the right-hand side of the spindle.

Wheel Safety

- Ring test: new wheels must be tested for cracks.

- Ensure correct plastic wheel bushings are used.

- Wheel blotter:

- Check the blotter glued to the wheel to ensure the machine's RPM is slower than the grinding wheel's maximum RPM.

- Blotters must be in place on both sides of the wheel prior to mounting.

- Wheel flange inspection:

- Check for nicks and marks on the surface of the flange.

- Flanges must contact the blotter.

Wheel Maintenance

- Dressing and truing:

- Glazed wheel: a condition where the wheel takes on a glass-like appearance, caused by grain wearing away faster than the wheel bonding material.

- Loaded grinding wheel: when workpiece chips adhere to the cutting face of the wheel, caused by grinding non-ferrous materials and wheels that are too hard.

- Wheel dressing: removes the top surface of the grinding wheel periphery to expose new grit.

- Truing a wheel: performed when an out-of-round wheel causes a vibration throughout the grinder, ensuring the wheel is running true to the axis of the spindle.

Grinding Operations

- Pedestal grinder operations:

- Grinding a prick or center punch.

- Repairing a flat screwdriver.

- Drill bit sharpening.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.