Podcast

Questions and Answers

What is the primary function of lubrication in an engine?

What is the primary function of lubrication in an engine?

- To increase engine power output.

- To promote overheating of engine components.

- To reduce contact between metal surfaces. (correct)

- To increase friction between metal parts.

Engine lubricants are suitable for use at normal temperatures and low pressures.

Engine lubricants are suitable for use at normal temperatures and low pressures.

False (B)

The ACEA standard classifies oils for gasoline and diesel engines with light loads under class ______.

The ACEA standard classifies oils for gasoline and diesel engines with light loads under class ______.

A/B

Which of the following is NOT a characteristic of good engine oil?

Which of the following is NOT a characteristic of good engine oil?

Match the oil type with its composition:

Match the oil type with its composition:

Name three functions of the oil, besides lubrication.

Name three functions of the oil, besides lubrication.

What does 'SAE' refer to in the classification of oils?

What does 'SAE' refer to in the classification of oils?

Monograde oils have a viscosity range, while multigrade oils have a single viscosity number.

Monograde oils have a viscosity range, while multigrade oils have a single viscosity number.

The process of supplying lubricant through channels under pressure is known as ______ lubrication.

The process of supplying lubricant through channels under pressure is known as ______ lubrication.

Which of the following components is NOT typically lubricated under pressure in an engine?

Which of the following components is NOT typically lubricated under pressure in an engine?

What leads to increased oil consumption in an engine?

What leads to increased oil consumption in an engine?

Oil filters should negligibly oppose the passage of oil through them.

Oil filters should negligibly oppose the passage of oil through them.

Match the component with its function in the lubrication system:

Match the component with its function in the lubrication system:

What does the oil pressure switch indicate?

What does the oil pressure switch indicate?

The oil change is usually performed approximately every ______ to 30,000 km.

The oil change is usually performed approximately every ______ to 30,000 km.

Flashcards

What is Lubrication?

What is Lubrication?

To avoid or reduce contact between metals, preventing wear, overheating, and power loss.

Functions of Oil

Functions of Oil

Reduces friction, cools, improves compression, absorbs stress, cleans, and transports wear particles.

Motor Oil

Motor Oil

Lubricants that withstand high temperatures and pressures, forming a protective film to prevent corrosion.

Characteristics of Motor Oils

Characteristics of Motor Oils

Signup and view all the flashcards

Synthetic Oils

Synthetic Oils

Signup and view all the flashcards

Oil Additives

Oil Additives

Signup and view all the flashcards

Viscosity

Viscosity

Signup and view all the flashcards

Oil Classification

Oil Classification

Signup and view all the flashcards

Lubrication System Function

Lubrication System Function

Signup and view all the flashcards

Pressure lubrication

Pressure lubrication

Signup and view all the flashcards

Oil Coolers

Oil Coolers

Signup and view all the flashcards

The Oil Sump

The Oil Sump

Signup and view all the flashcards

Oil Pump Function

Oil Pump Function

Signup and view all the flashcards

Oil Pump

Oil Pump

Signup and view all the flashcards

Filtration

Filtration

Signup and view all the flashcards

Study Notes

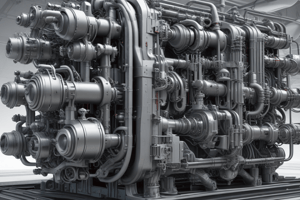

Lubrication System

- Lubrication aims to prevent or minimize contact between metal surfaces.

- Friction causes wear, heat, and power loss.

- Friction converts mechanical energy into heat.

- Oil facilitates heat evacuation.

Types of Lubrication

- Dry: Direct contact leads to high temperatures.

- Semifluid: Reduced friction between components.

- Fluid: Components are entirely separated by oil.

Oil Functions

- Minimizes friction and mechanical losses.

- Cools components.

- Improves compression.

- Dampens and softens stress.

- Cleans and transports wear particles.

Motor Oil

- Motor lubricants must resist high temperatures and pressures.

- They create a film that adheres to surfaces, preventing corrosion.

- Maintain viscosity and fluidity.

- Burn without leaving residues.

- Last for a long time.

Oil Types

- Mineral: Mineral + Additives.

- Synthetic: Synthetic + Additives.

- Good fluidity in auto.

- Stable viscosity.

- Resistant to oxidation.

- Reduces friction.

- Semi-synthetic: Mineral + Synthetic + Additives.

Oil Additives

- Improve quality with antioxidants, anti-wear additives, detergents, and dispersants.

Viscosity

- Viscosity describes a liquid's resistance to flow.

- Viscous oil means more pressure is needed.

- Fluid oil means less.

- Temperature impacts viscosity.

- Engine off: 0 degrees.

- Engine starting: 100 degrees.

Oil Classification

- Based on viscosity grade by SAE; for service conditions: API and ACEA.

Viscosity Ratings

- 0 to 25 are for low temperatures (W).

- 20 to 60 denote the oil's viscosity when hot.

Oil Grades

- Monograde: Single viscosity number.

- Multigrade: Viscosity range, e.g., -5°C to 35°C for SAE 20W-40.

Service Conditions

- ACEA is common in Europe, with military and companies making their own.

API

- Each category is superior to the previous one.

- It is better for the old engine to be in a good category.

Diesel

- Each category corresponds to different operating categories.

ACEA Classes

- A/B: Gasoline and diesel (light).

- C: Otto and diesel with exhaust gas treatment.

- E: Diesel (heavy).

Engine Lubrication System

- Purpose: To supply oil for lubrication, using

- Pressure lubrication (greixatge a pressió).

- Mixture with the combustible (greixatge per mescla amb-le combustible).

Pressure Lubrication

- Supplies lubricant through channels.

- Oil is drawn from the sump through a filter by a pump.

- Passes through the main line and is distributed to necessary points.

- An outlet valve limits maximum pressure.

Components Lubricated Under Pressure

- Crankshaft supports, valve rocker supports, rocker arm shafts, connecting rod end.

Impregnation Lubrication

- Oil is sprayed as a mist, which then impregnates.

Parts Lubricated with Impregnation

- Cylinders, connecting rod ends, valve guides, chain, internal engine elements.

Oil Cooling

- Accomplished by air flow.

Oil Coolers

- Use heat exchangers.

- Water-oil interchanger.

- Air-oil interchanger.

- Water-oil: Two independent circuits, one for oil and another for coolant.

- Air-oil: Radiator circulates oil, air cools it; a thermostatic valve controls oil flow.

Piston Cooling

- For high-performance or direct-injection diesel engines.

- Reduces each piston's temperature.

Mixture Lubrication

- Used in two-stroke engines.

- The oil adheres or burns.

Pressure Lubrication Circuit Components

- Oil Sump (Carter).

- Located at the bottom of the engine and helps cool it.

- Baffles prevent the pump from running without oil during sudden movements.

- Oil Pump.

- Creates flow and pressure, powered by the crankshaft.

- Includes a filter and a discharge valve.

- Types include gear, rotor, and internal gear pumps.

Gear Pump Operation

- Two gears rotate in opposite directions.

- Creates a vacuum for the suction chamber and pressure on the output.

Rotor Pump Operation

- Rotor interior and rotor exterior makes two chambers.

- The number of teeth is different to make the cambers.

- The movement comes from the rotor interior

- Functions similarly to gear pumps

Discharge Valve Function

- Controls pressure; prevents over- or under-pressurization.

- Low pressure: valve closed; high pressure: valve open.

Oil Filtering

- Necessary to maintain and protect the oil, employing:

- Suction filter removes large particles.

- Main filter removes impurities and dust.

Oil Filtration Types

- Series Filtration (majority): If filter clogs, the pump continues to function.

- Bypass Filtration: Oil is filtered and returned to the sump.

Oil Filters

- Must provide low resistance to oil flow.

- Cartridge/disposable type.

- Dismountable filter.

Manocontact

- Located in the main line to detect a lack of pressure.

- Low pressure, light illuminates.

- Sufficient pressure, light turns off.

Oil Level Sensors

- Installed at the bottom of the oil pan.

- Detects lack of oil and reports to the control panel.

Flexible Service Intervals

- Based on oil level, temperature, kilometers, and consumption to determine oil condition.

Crankcase Ventilation

- Channels gases from the crankcase for combustion.

Lubrication Maintenance

- Oil loses qualities over time, making changes important.

- Clean filter provides flow.

Regular Maintenance

- Oil level check.

- Oil change.

- Filter change.

Oil Level Check

- Turn on engine for 1 minutes.

- Stop engine for 1 minutes.

- Remove and clean dipstick.

- Insert the dipstick.

- Remove and check the level.

- Oil consumption increases as the engine ages, caused by:

- Low quality oil.

- High temperatures.

- Overfilled w/ oil.

- Carbon buildup.

- Worn cylinders, rings, and segments.

- Worn turbocharger bearings.

Oil Consumption Test

- Start the engine.

- Weigh the oil.

- Drive between 300 and 500 km.

- Reweigh the oil.

Oil and Filter changes

- Typically needed every 15,000 to 30,000 km.

Negative Conditions

- Short trips.

- Frequent stops.

- High engine loads.

- Gas leaks towards the sump.

- Dusty environments.

Oil Change Steps

- Remove the plug.

- Drain the oil.

- Remove the filter.

- Clean the support.

- Install the new filter (oil the seal).

- Replace the plug.

Lubrication System Checks

Oil Pressure Check

- Necessary: Manometer

- Process: Remove the motor, sample at specified revolutions, and evaluate w/ manometer measurement.

Pressure Issues

- Low pressure causes:

- Worn pump.

- Defective relief valve.

- Excessive clearances.

- Obstructed filter.

- Poor oil quality.

- High pressure causes:

- Faulty relief valve.

- Clogged ducts.

- Blocked filter.

Pump/Valve Inspection and Disassembly

- Drain oil, remove the sump, and remove the pump.

- Disassemble the pump, check, cleaning and reassembling and ensure elements are free

- Using gauges to measure pumps components

Gear Pump Checks:

Rotor Pump Checks

Internal Gear Pump Checks

Relief Valves

- Springs that maintains elasticity and force.

- Carefully disassemble the seat.

- Inpect the pieces

- Lubricate the joint system.

- Mount the case with a moves joint, and test the oil preasure.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.