Podcast

Questions and Answers

How do lubricants reduce wear and tear in machines?

How do lubricants reduce wear and tear in machines?

Lubricants reduce wear and tear by minimizing friction between moving parts.

What conditions typically apply to thick film lubrication?

What conditions typically apply to thick film lubrication?

Thick film lubrication occurs under high-speed, low-load conditions.

Describe the role of oil in a journal bearing.

Describe the role of oil in a journal bearing.

Oil in a journal bearing creates a hydrodynamic wedge that supports the rotating shaft, reducing friction.

What effect does a low coefficient of friction have in lubrication systems?

What effect does a low coefficient of friction have in lubrication systems?

How does hydrodynamic lubrication function in relation to oil films?

How does hydrodynamic lubrication function in relation to oil films?

What is one of the key functions of lubricants?

What is one of the key functions of lubricants?

In thick film lubrication, how thick is the oil film typically?

In thick film lubrication, how thick is the oil film typically?

What does hydrodynamic wedging in a journal bearing primarily facilitate?

What does hydrodynamic wedging in a journal bearing primarily facilitate?

What role do oil molecules play in thick film lubrication?

What role do oil molecules play in thick film lubrication?

What is a characteristic of the coefficient of friction in thick film lubrication?

What is a characteristic of the coefficient of friction in thick film lubrication?

Flashcards

Lubricant function - Wear

Lubricant function - Wear

Lubricants decrease the friction between moving parts in a machine, reducing wear and tear.

Thick Film Lubrication

Thick Film Lubrication

A type of lubrication where a thick oil film (1000 Å) separates the moving surfaces, preventing direct contact.

Thick Film Lubrication - Friction

Thick Film Lubrication - Friction

In thick film lubrication, the friction coefficient is very low (e.g., 0.01 to 0.03).

Journal Bearing - Composition

Journal Bearing - Composition

Signup and view all the flashcards

Lubricant function - Temperature

Lubricant function - Temperature

Signup and view all the flashcards

Lubricant's primary role

Lubricant's primary role

Signup and view all the flashcards

Lubricant benefit - Temperature

Lubricant benefit - Temperature

Signup and view all the flashcards

Thick film lubrication - Speed

Thick film lubrication - Speed

Signup and view all the flashcards

Thick film lubrication - Load

Thick film lubrication - Load

Signup and view all the flashcards

Journal Bearing - How it works

Journal Bearing - How it works

Signup and view all the flashcards

Study Notes

Lubricant Function

- Lubricants reduce wear and tear by creating a thin film between moving surfaces.

- This film prevents direct contact between the surfaces, reducing friction and heat generation.

- This film also carries away contaminants and heat, further reducing wear.

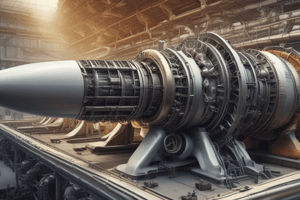

Thick Film Lubrication

- Thick film lubrication occurs when the lubricant film is thick enough to separate the moving surfaces completely.

- This typically happens at high speeds and loads, where the lubricant is forced into the contact zone by the motion of the surfaces.

- Thick film lubrication is desirable because it provides the best protection against wear.

Oil in a Journal Bearing

- In a journal bearing, the oil forms a wedge-shaped film between the rotating shaft and the bearing.

- The wedge shape is created by the rotation of the shaft, which forces the oil to flow around the bearing.

- This flow generates a pressure that supports the shaft and reduces friction.

Low Coefficient of Friction

- A low coefficient of friction means that less force is required to overcome friction between two surfaces.

- This reduces energy loss and heat generation in lubrication systems.

- It also improves the efficiency and longevity of the machine.

Hydrodynamic Lubrication

- Hydrodynamic lubrication relies on the motion of the surfaces to generate a pressure in the lubricant film.

- This pressure is sufficient to support the load and separate the surfaces.

- This type of lubrication is common in journal bearings and other applications where high speeds and loads are involved.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.