Podcast

Questions and Answers

What primarily causes the amplification of tensile stress at the tip of a small incision or notch?

What primarily causes the amplification of tensile stress at the tip of a small incision or notch?

- The environmental conditions during packaging

- The type of material used in packaging

- The applied tensile stress (correct)

- The size of the incision or notch

What type of failure does creep represent?

What type of failure does creep represent?

- Brittle failure

- Tensile failure

- Dynamic failure (correct)

- Static failure

Which case study illustrates brittle fracture due to crack propagation?

Which case study illustrates brittle fracture due to crack propagation?

- A bridge collapse during a storm

- An oil tank fracturing around its girth (correct)

- A water pipe bursting in freezing temperatures

- A commercial aircraft experiencing explosive decompression

What contributed to the metal fatigue in the Boeing 737-200 aircraft?

What contributed to the metal fatigue in the Boeing 737-200 aircraft?

What is one of the characteristics of ductile fractures?

What is one of the characteristics of ductile fractures?

What environmental factor aggravated the metal fatigue in the Boeing 737-200?

What environmental factor aggravated the metal fatigue in the Boeing 737-200?

What is the primary distinction between static failures and dynamic failures?

What is the primary distinction between static failures and dynamic failures?

How did the small notch on the oil tank contribute to its failure?

How did the small notch on the oil tank contribute to its failure?

What is the primary cause of deformation in elastic failure?

What is the primary cause of deformation in elastic failure?

Which material failure type is characterized by non-recoverable deformation?

Which material failure type is characterized by non-recoverable deformation?

What primarily distinguishes static from dynamic loading in fracture types?

What primarily distinguishes static from dynamic loading in fracture types?

What type of fracture involves varying cycle and loading magnitude?

What type of fracture involves varying cycle and loading magnitude?

Which of the following best describes fretting corrosion?

Which of the following best describes fretting corrosion?

What happens to a piece of paper when it is notched before applying force?

What happens to a piece of paper when it is notched before applying force?

In the context of tensile tests, what does a simple fracture indicate?

In the context of tensile tests, what does a simple fracture indicate?

Which factor can accelerate the process of creep in materials?

Which factor can accelerate the process of creep in materials?

What determines the fracture pattern of a folded paper compared to an intact paper?

What determines the fracture pattern of a folded paper compared to an intact paper?

Which of the following statements about ductile and brittle fracture is correct?

Which of the following statements about ductile and brittle fracture is correct?

What type of loading is primarily associated with fatigue failure?

What type of loading is primarily associated with fatigue failure?

What is a potential consequence of excessive deformation in a rubber band?

What is a potential consequence of excessive deformation in a rubber band?

Under which condition would a material exhibit the least resistance to fracture?

Under which condition would a material exhibit the least resistance to fracture?

How does relaxation occur in materials over time?

How does relaxation occur in materials over time?

What characterizes the fracture surface of ductile materials?

What characterizes the fracture surface of ductile materials?

Which materials are noted for showing nearly 100% necking before fracture?

Which materials are noted for showing nearly 100% necking before fracture?

The crack in ductile materials grows primarily due to which mechanism?

The crack in ductile materials grows primarily due to which mechanism?

What does a brittle fracture typically lack?

What does a brittle fracture typically lack?

Which type of fracture exhibits a characteristic 'cup-and-cone' surface?

Which type of fracture exhibits a characteristic 'cup-and-cone' surface?

The direction of crack motion in brittle materials is primarily:

The direction of crack motion in brittle materials is primarily:

What is one of the key indicators of a brittle material's fracture surface?

What is one of the key indicators of a brittle material's fracture surface?

How can ductility in certain metals be improved?

How can ductility in certain metals be improved?

What is a feature of brittle fracture in amorphous materials?

What is a feature of brittle fracture in amorphous materials?

What happens during the initial necking stage in ductile fracture?

What happens during the initial necking stage in ductile fracture?

How do the fracture surfaces of very hard and fine-grained metals typically appear?

How do the fracture surfaces of very hard and fine-grained metals typically appear?

What term is used to describe the fracture process that passes through the grains in brittle materials?

What term is used to describe the fracture process that passes through the grains in brittle materials?

What defines the distinctive pattern of a brittle fracture?

What defines the distinctive pattern of a brittle fracture?

What happens after the microvoids coalesce in ductile fracture?

What happens after the microvoids coalesce in ductile fracture?

Flashcards

Material Failure

Material Failure

The failure of a material due to stress, environmental conditions or flaws.

Ductile Fracture

Ductile Fracture

A type of fracture characterized by significant plastic deformation before failure.

Brittle Fracture

Brittle Fracture

A type of fracture that occurs without any significant plastic deformation; sudden and rapid breaks.

Crack Propagation

Crack Propagation

Signup and view all the flashcards

Creep

Creep

Signup and view all the flashcards

Stress Relaxation

Stress Relaxation

Signup and view all the flashcards

Fatigue

Fatigue

Signup and view all the flashcards

Corrosion

Corrosion

Signup and view all the flashcards

Ductility

Ductility

Signup and view all the flashcards

Necking

Necking

Signup and view all the flashcards

Microvoids

Microvoids

Signup and view all the flashcards

Cup-and-Cone Fracture

Cup-and-Cone Fracture

Signup and view all the flashcards

Chevron Markings

Chevron Markings

Signup and view all the flashcards

Cleavage

Cleavage

Signup and view all the flashcards

Transgranular Fracture

Transgranular Fracture

Signup and view all the flashcards

Fracture Surface Patterns

Fracture Surface Patterns

Signup and view all the flashcards

Energy Absorption in Fractures

Energy Absorption in Fractures

Signup and view all the flashcards

Moderate Ductility

Moderate Ductility

Signup and view all the flashcards

High Ductility Examples

High Ductility Examples

Signup and view all the flashcards

Flat Fracture Surfaces

Flat Fracture Surfaces

Signup and view all the flashcards

Maintenance Program

Maintenance Program

Signup and view all the flashcards

Material Failure Types

Material Failure Types

Signup and view all the flashcards

Deformation Failure

Deformation Failure

Signup and view all the flashcards

Elastic Deformation

Elastic Deformation

Signup and view all the flashcards

Plastic Deformation

Plastic Deformation

Signup and view all the flashcards

Creep Failure

Creep Failure

Signup and view all the flashcards

Fracture Types

Fracture Types

Signup and view all the flashcards

Dynamic Loading

Dynamic Loading

Signup and view all the flashcards

Fretting Corrosion

Fretting Corrosion

Signup and view all the flashcards

Simple Fracture

Simple Fracture

Signup and view all the flashcards

Notched Paper Experiment

Notched Paper Experiment

Signup and view all the flashcards

Folded Paper Experiment

Folded Paper Experiment

Signup and view all the flashcards

Tensile Test

Tensile Test

Signup and view all the flashcards

Study Notes

Introduction to Material Failure

- Material failure can be static (ductile, brittle) or dynamic (creep, stress relaxation, fatigue)

- Applied tensile stress amplifies at notch/incision tips, making it easier to tear materials

- Material failures have caused significant disasters throughout history, highlighting the importance of understanding them.

Case Studies of Material Failure

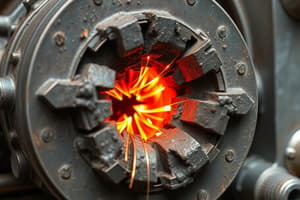

- 300-meter long oil tank fractured due to crack propagation originating from a small flaw, amplified by stress at sea

- Boeing 737-200 experienced explosive decompression. Metal fatigue, exacerbated by crevice corrosion from a humid and salty coastal environment

- Stress cycling of the fuselage from compression and decompression during short hops

- Proper maintenance would have detected and prevented this accident.

Material Failure Types

- Mechanical failures categorized into deformation-related (time-dependent, time-independent) and fracture (static, dynamic).

- Elastic deformation can be a type of failure, as it may fail to achieve desired goals. Examples include a fork bending on wood. Rubber band stretching beyond ability or plastic deformation.

- Time-dependent failures include creep (increasing deformation under constant stress) and stress relaxation (reducing load under constant deformation). These are sensitive to elevated temperatures.

- Static fracture is categorized into ductile and brittle.

- Dynamic failures include fatigue (repeated loading), fretting corrosion (repetitive mechanical contact). Example: hip joint implant, vibration-related scenarios.

Simple Fracture

- Simple fracture is the separation of a body into pieces. Due to imposed static stress/constant/minimal changing stress/slow varying with low temperature.

- Categorized into ductile (substantial plastic deformation, high energy absorption) and brittle (little or no plastic deformation, low energy absorption).

- Ductile materials have inclined fracture planes; brittle materials have flat fracture surfaces.

- Ductility is relative and depends on temperature, strain rate, stress state.

- Burst pipes: cast iron/brass (brittle) fracture into small pieces with little deformation, whereas ductile pipes deform significantly before fracturing.

Stages of Ductile Fracture

- Flaws are inevitable.

- Five stages from necking to fracture: initiation of microvoids/cavities - enlargement and coalescence - formation of crack - crack propagation to exterior - rupture via shear deformation.

- Shear deformation occurs at 45 degrees to the tensile loading axis(maximum shear stress) yielding a cup-and-cone fracture.

- Interior regions show irregular/fibrous plastic deformation.

Features of Brittle Fracture

- Brittle fracture happens with negligible visible deformation, rapid crack propagation, and flat fracture surfaces.

- Fracture surfaces have distinctive patterns like V-shaped markings (chevron pattern), radiating lines/ridges, which point back towards the origin of initiation of crack

- Patterns diminish with reducing grain size (increasing stiffness) and diminish in amorphous material due to the random microstructure.

- Crack propagation in crystalline materials aligns along specific crystallographic planes (cleavage) through grain (transgranular).

- Sometimes crack propagation is along grain boundaries (intergranular).

In-Class Paper Fracture Demonstration

- Demonstrates how notches/folded papers make it easier to tear paper

- Fracture patterns differ depending on type of treatment to paper.

In-class Quiz

- Revision of previous module/term.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.