Podcast

Questions and Answers

What is the primary goal of Lean Manufacturing?

What is the primary goal of Lean Manufacturing?

- To reduce waste and improve efficiency (correct)

- To decrease labor costs

- To increase production volume

- To implement new technologies

Which type of manufacturing involves creating products by adding layer upon layer of material?

Which type of manufacturing involves creating products by adding layer upon layer of material?

- Process manufacturing

- Discrete manufacturing

- Additive manufacturing (correct)

- CNC machining

What is the primary purpose of quality control in manufacturing?

What is the primary purpose of quality control in manufacturing?

- To implement new technologies

- To ensure consistency and quality of products (correct)

- To reduce labor costs

- To increase production speed

What is the term for the careful selection of materials for a specific product or application?

What is the term for the careful selection of materials for a specific product or application?

What is the primary focus of the '5S' methodology in Lean Manufacturing?

What is the primary focus of the '5S' methodology in Lean Manufacturing?

What is the primary focus of Production Planning and Control?

What is the primary focus of Production Planning and Control?

What is the purpose of On-the-Job Training?

What is the purpose of On-the-Job Training?

What is the primary goal of Continuous Improvement in training programs?

What is the primary goal of Continuous Improvement in training programs?

What is the purpose of Feedback Mechanism in training programs?

What is the purpose of Feedback Mechanism in training programs?

What is the primary benefit of using Interactive Learning in training programs?

What is the primary benefit of using Interactive Learning in training programs?

Flashcards are hidden until you start studying

Study Notes

Introduction to Manufacturing

- Manufacturing is a crucial aspect of the economy, and understanding its definition and importance is essential.

- The history of manufacturing is marked by significant advancements, including the introduction of new technologies and materials.

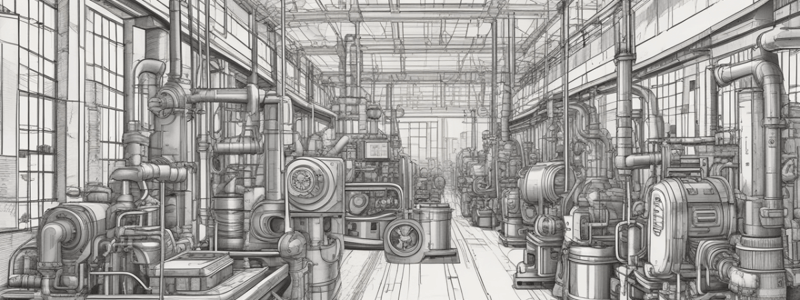

Manufacturing Processes

- Basic processes in manufacturing include casting, molding, machining, joining, and additive manufacturing (3D printing).

- Advanced techniques in manufacturing include CNC machining, robotics, and automation.

- Lean manufacturing concepts, such as Kaizen, 5S, and Six Sigma, aim to improve efficiency and reduce waste.

Materials in Manufacturing

- Common types of materials used in manufacturing include metals, plastics, ceramics, and composites.

- Material properties, such as strength, hardness, and ductility, significantly impact manufacturing choices.

- Material selection criteria include factors such as cost, corrosion resistance, and durability.

Manufacturing Equipment and Tools

- Essential machinery in manufacturing includes lathes, mills, and injection molding machines.

- Basic hand tools and measuring instruments are used in various manufacturing processes.

- Regular maintenance of equipment and tools is crucial for efficient production.

Quality Control

- Quality control involves adhering to standards and certifications, such as ISO standards and quality management systems.

- Inspection methods include visual inspections, non-destructive testing, and statistical process control.

- Continuous quality improvement strategies are necessary for ongoing quality enhancement.

Safety in Manufacturing

- Common hazards in manufacturing include fire, electrical shock, and equipment malfunctions.

- Personal Protective Equipment (PPE) includes items such as gloves, goggles, and respirators.

- Safety protocols include emergency procedures, safety drills, and regular training.

Manufacturing Technologies

- Automation and robotics play a significant role in modern manufacturing, increasing efficiency and productivity.

- Digital manufacturing technologies include CAD/CAM, IoT, and Industry 4.0.

- Sustainable manufacturing practices aim to reduce environmental impact through efficient energy use and waste reduction.

Manufacturing Management

- Production planning and control involve managing production schedules, inventory, and logistics.

- Supply chain management principles include minimizing inventory, optimizing transportation, and ensuring quality.

- Project management in manufacturing involves tools and techniques for managing projects, such as Gantt charts and resource allocation.

Hands-On Training

- Practical workshops provide hands-on experience with machinery and tools.

- Simulations using software help learners understand manufacturing processes.

- On-the-job training under supervision provides real-world experience.

Assessment and Feedback

- Periodic quizzes and exams assess learners' understanding of manufacturing concepts.

- Practical tests evaluate learners' practical skills.

- Regular feedback mechanisms help learners improve and identify areas for development.

Implementation Tips

- Interactive learning methods, such as videos and virtual tours, enhance learner engagement.

- Experienced instructors with real-world experience provide valuable insights.

- Regular updates to training content ensure that learners receive the latest industry trends and technologies.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.