Podcast

Questions and Answers

Which of the following best describes machining?

Which of the following best describes machining?

- Altering the properties of a metal through heat treatment

- Joining two or more workpieces together using heat and pressure

- Removing or separating metal using a cutting tool on a machine tool (correct)

- Adding material to a workpiece to achieve the desired shape

What term is used to describe machining equipment such as mills, lathes, and drill presses?

What term is used to describe machining equipment such as mills, lathes, and drill presses?

- Processing center

- Fabrication unit

- Cutting station

- Machine tool (correct)

What is the common name for an area that houses machine tools?

What is the common name for an area that houses machine tools?

- Assembly line

- Production floor

- Manufacturing plant

- Machine shop (correct)

What are cutting tools in machining typically made from?

What are cutting tools in machining typically made from?

Machining is commonly known as what type of manufacturing process?

Machining is commonly known as what type of manufacturing process?

Which of the following operations is LEAST likely to be performed by a machine tool?

Which of the following operations is LEAST likely to be performed by a machine tool?

Which of the following is NOT considered a traditional machine tool?

Which of the following is NOT considered a traditional machine tool?

Which metal removal method uses a blade to cut material?

Which metal removal method uses a blade to cut material?

Which metal removal method relies on abrasives?

Which metal removal method relies on abrasives?

Which metal removal method does NOT use mechanical energy?

Which metal removal method does NOT use mechanical energy?

Which of the following is a conventional machining operation that uses a sharp cutting tool?

Which of the following is a conventional machining operation that uses a sharp cutting tool?

What does the conventional machining process of 'turning' primarily involve?

What does the conventional machining process of 'turning' primarily involve?

Which machining operation is characterized by creating internal surfaces or profiles similar to those produced by turning?

Which machining operation is characterized by creating internal surfaces or profiles similar to those produced by turning?

Which operation is often used to improve the accuracy of drilled holes?

Which operation is often used to improve the accuracy of drilled holes?

Which machining process is generally NOT suitable for mass production?

Which machining process is generally NOT suitable for mass production?

Which machining process is best suited for creating flat surfaces and straight contour profiles on a relatively small workpiece?

Which machining process is best suited for creating flat surfaces and straight contour profiles on a relatively small workpiece?

Which of the following is a disadvantage of machining?

Which of the following is a disadvantage of machining?

What is the primary reason machining is often used as a secondary manufacturing process?

What is the primary reason machining is often used as a secondary manufacturing process?

When is abrasive machining typically used?

When is abrasive machining typically used?

Which of the following materials is commonly used in abrasive wheels?

Which of the following materials is commonly used in abrasive wheels?

Which of the following is a key characteristic of non-traditional machining methods compared to traditional machining?

Which of the following is a key characteristic of non-traditional machining methods compared to traditional machining?

Chemical Machining (CM) is based on what principle?

Chemical Machining (CM) is based on what principle?

What is a common application of Chemical Machining (CM)?

What is a common application of Chemical Machining (CM)?

What is the fundamental principle behind Electro Discharge Machining (EDM)?

What is the fundamental principle behind Electro Discharge Machining (EDM)?

For which types of material is Electro-Discharge Machining (EDM) suitable?

For which types of material is Electro-Discharge Machining (EDM) suitable?

What specific type of cutting is Wire EDM similar to?

What specific type of cutting is Wire EDM similar to?

What materials are commonly used to make the wire in Wire EDM?

What materials are commonly used to make the wire in Wire EDM?

What is the main mechanism of material removal in Laser Beam Machining?

What is the main mechanism of material removal in Laser Beam Machining?

Besides cutting and drilling, what other applications can Laser Beams be used for?

Besides cutting and drilling, what other applications can Laser Beams be used for?

Which of the following is a key difference between plasma arc cutting and laser beam machining?

Which of the following is a key difference between plasma arc cutting and laser beam machining?

To operate, Plasma Cutting requires what kind of a workpiece?

To operate, Plasma Cutting requires what kind of a workpiece?

What role does water play in Water Jet Cutting Machining?

What role does water play in Water Jet Cutting Machining?

What types of materials are best suited for Water Jet Cutting Machining?

What types of materials are best suited for Water Jet Cutting Machining?

Which of the following properties is LEAST likely to be changed by Water Jet Cutting Machining?

Which of the following properties is LEAST likely to be changed by Water Jet Cutting Machining?

What is a key consideration when selecting a machining process for a particular application?

What is a key consideration when selecting a machining process for a particular application?

How do tolerances most directly influence the ultimate cost of a machined part?

How do tolerances most directly influence the ultimate cost of a machined part?

Flashcards

What is machining?

What is machining?

Removing or separating metal using a cutting tool on a Machine Tool.

What is a Machine Tool?

What is a Machine Tool?

Equipment used for machining, including mills, lathes, and drill presses.

What is a Machine Shop?

What is a Machine Shop?

A workshop or area where machine tools are housed.

What are tool steels?

What are tool steels?

Signup and view all the flashcards

What is a machine tool?

What is a machine tool?

Signup and view all the flashcards

What is machine tooling?

What is machine tooling?

Signup and view all the flashcards

What is sawing?

What is sawing?

Signup and view all the flashcards

What is filing?

What is filing?

Signup and view all the flashcards

What is grinding?

What is grinding?

Signup and view all the flashcards

What is Non-Traditional Machining?

What is Non-Traditional Machining?

Signup and view all the flashcards

What is conventional machining?

What is conventional machining?

Signup and view all the flashcards

What is milling?

What is milling?

Signup and view all the flashcards

What is turning?

What is turning?

Signup and view all the flashcards

What is boring?

What is boring?

Signup and view all the flashcards

What is drilling?

What is drilling?

Signup and view all the flashcards

What is tapping?

What is tapping?

Signup and view all the flashcards

What is shaping?

What is shaping?

Signup and view all the flashcards

What is sawing?

What is sawing?

Signup and view all the flashcards

What are disadvantages of machining?

What are disadvantages of machining?

Signup and view all the flashcards

Why is machining used as a secondary process?

Why is machining used as a secondary process?

Signup and view all the flashcards

What is abrasive machining?

What is abrasive machining?

Signup and view all the flashcards

What is chemical machining?

What is chemical machining?

Signup and view all the flashcards

What is Electro Discharge Machining (EDM)?

What is Electro Discharge Machining (EDM)?

Signup and view all the flashcards

What is Wire EDM?

What is Wire EDM?

Signup and view all the flashcards

What is Laser Beam Machining?

What is Laser Beam Machining?

Signup and view all the flashcards

What is Plasma Arc Cutting?

What is Plasma Arc Cutting?

Signup and view all the flashcards

What is Abrasive Water-Jet Machining?

What is Abrasive Water-Jet Machining?

Signup and view all the flashcards

What are traditional milling operations?

What are traditional milling operations?

Signup and view all the flashcards

Study Notes

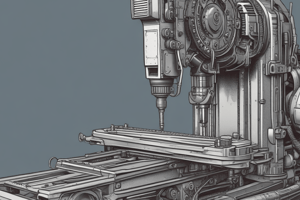

- Machining is removing or separating metal using a cutting tool on a Machine Tool, also known as "Subtractive Manufacturing."

- The term "Machine Tool" describes machining equipment like mills, lathes, and Drill Presses.

- The cutting tools are called “Tool steels"

- An area that houses machine tools is called a “Machine Shop"

Machine Tool

- It is any tool that is used to remove material, typically metal.

- Anything that drills, mills, turns, grinds, etches, or cuts is considered a machine tool.

Common Machine Tools

- Milling Machines

- Lathe

- Drill Press

- Band Saw

Common Ways of Machining or Metal Removal

- Machine tool: Metal removal uses a cutting tool

- Sawing: Metal removal uses a blade to cut

- Filing: Metal removal uses a file to remove material

- Grinding: Metal removal uses abrasives to remove

- Non-Traditional machining: Metal removal uses other than mechanical energy to remove material

Material Removal Processes

- Material Removal Processes fall into three groups: Conventional Machining, Abrasive Processes, and Non-Traditional Machining

- Conventional Machining involves turning and related operations, drilling and related operations, milling, and other machining operations

- Abrasive Processes involve grinding operations and other abrasive processes

- Non-Traditional Machining involves mechanical energy processes, electrochemical machining, thermal energy processes, and chemical machining

Conventional Machining Operations

- Material removal uses a sharp cutting tool.

- Milling

- Reaming

- Planing

- Turning

- Tapping

- Broaching

- Boring

- Sawing

- Drilling

- Shaping

Conventional Machining: Milling

- Milling covers versatile machining operations using a milling cutter.

- Traditional Milling Operations include facing, 3D machining, boring, pockets, side milling, tapping, slots and Drilling and Reaming

Conventional Machining: Turning

- Turning means the part is rotating while it is being machined using a cutting tool.

- The starting material typically is a workpiece which has been produced by other processes, such as casting, forging, and extrusion.

- Turning and facing operations are performed on all types of materials.

- It requires Skill labor.

- It has a low production rate, but medium to high rates can be achieved with turret lathes and automatic machines

Conventional Machining: Boring

- Uses internal surfaces or profiles, with similar characteristics produced from turning

- Stiffness of boring bar is important to avoid chatter.

- Typically used to increase accuracy; requires the use of skilled labor.

Conventional Machining: Drilling

- Drilling is used for making round holes of various sizes and depths.

- It requires boring and reaming for improved accuracy.

- High production rates.

- The labor skill required depends on hole location and accuracy specified

Conventional Machining: Tapping

- Not suitable for mass production

- External and Internal Threads

Conventional Machining: Shaping

- Used for flat surfaces and straight contour profiles on relatively small workpiece.

- Suitable for low-quantity production.

- Skill labor required depends on part and shape.

Other Macining Operations: Broaching

- Operations include Chip gullet; Rake or hook angle; Land; Pitch; Back-off or clearance angle; Cut per tooth; Workpiece and Root radius

Conventional Machining: Sawing

- Used for straight and contour cuts on flats or structural shapes.

- It isn't suited for hard materials unless the blade has carbide teeth or is coated with diamonds.

- It has a low production rate and only requires low skilled labor

Important Questions About Machining

- What is the cutting speed and why is it important?

- How do we calculate rpms?

- What is meant by hardness and what is toughness?

- How we make precise holes - what tools are needed?

- What types of equipment do we use in a metrology lab and why?

- Why are tolerances important in machining?

- What are implied tolerances?

- How do tolerances affect the cost of a part?

- How do tolerances affect how the part is made?

Disadvantages of Machining

- Wasteful of material because chips generated in machining are wasted material.

- Time consuming: A machining operation generally takes longer to shape a given part than alternative shaping processes.

- Costly: Machining is expensive and minimized for large production runs

Factors of Machining

- Machining is an expensive operation, which is often secondary in manufacturing.

- It is performed after basic manufacturing processes, such as casting and forging.

- Other processes create the general shape of the starting work part.

- Machining provides the final shape, dimensions, finish, and special geometric details that other processes cannot create

Abrasive Machining

- Primarily a Finishing Process

- It is followed up from a conventional operation,typically used for high dimensional finish and surface finish, typically used when the work piece is either too brittle or to hard

Abrasive Machining Tolerance

- Abraisive and Precision Measurements have .0001 in tolerance, this differs from more traditional Macining tolerance of .001 in

Abrasive Wheel chart

|Abrasive Wheel |Applications |

- -- | --- | Aluminum Oxide|Good for Steel and Aloys, Low Cost and High Volume options| Silicon Carbide | Good for cast iron and Non Ferrous Metaerials and Low cost| Diamond | Natural or man-made, best for carbrides and some non metalic materials and very High cost| Cubic Boron Nitride | Superior and Long life for high speed Steel and cutting very high cost

Types of Abrasive Machining

- Includes Grinding and Sand Blasting

Non-Traditional Machining

- Includes Chemical Machining, Electro-Chemical Machining, Electro Discharge Machining, Wire EDM, Laser Beam Machining, Plasma Arc-Cutting,and Abrasive Water-Jet Machine

Non-Traditional Machining: Chemical Machining (CM)

- Was developed on the observation that chemicals attack metals and etch them, that way removing minimal materials from a surface

- CM is the oldest of the non traditional machining processes, and has been used to engrave metals and hard stone

- Examples are the production of printed-circuit boards and microprocessors.

Non-Traditional Machining: Electro Discharge Machining (EDM)

- The principle is based on the erosion of medals by spark discharge

- it can be used on any material that is an electrical conductor, so the hardness, strength and toughness of the work piece do not necessarily influence the overall rate

Non-Traditional Machining: Laser Beam Machining

- Highly focused high density energy melts and evaporates portions of the work

- commonly used for drilling, cutting a variety of metallic and nonmetallic materials, ceramics and composites.

- Laser Beams are also used for Welding, Heat Treating, and Marking.

Non-Traditional Machining: Plasma Arc-Cutting

- Similar processes as laser beam machining

- Much cheaper but not as accurate

Non-Traditional Machining: Abrasive Water-Jet Machining

- The water acts as a saw to cut a small groove in the material

- Operations perfomred such as cutting holes, slots or inaccurate patterns using abrasive particles and hard brittle and non-metallic materials.

- Process allowing the use to cut holes as small as 3 MM in diameter with very accurate tolarenaces

- changes mechanical properties of materials, while a Water Jet Cutting Machine ranges in between $150,000-$300,000 dependin on size and capability.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.