Podcast

Questions and Answers

What is the primary purpose of machine drafting?

What is the primary purpose of machine drafting?

- To design machinery without technical specifications

- To visualize mechanical concepts without dimensions

- To create artistic representations of machinery

- To prepare working drawings for machine parts (correct)

Which factor is NOT typically considered when selecting materials for a machine part?

Which factor is NOT typically considered when selecting materials for a machine part?

- Artistic appeal (correct)

- Workability

- Strength

- Cost

What does the abbreviation 'ASTM' stand for in machine drafting?

What does the abbreviation 'ASTM' stand for in machine drafting?

- American Society for Testing Materials (correct)

- Applied Science and Technical Manufacturing

- Alliance of Simple Technical Methods

- Association for Standardized Technical Manufacturing

Which characteristic is important for a material regarding its usability in mechanical manufacturing?

Which characteristic is important for a material regarding its usability in mechanical manufacturing?

What does the term 'OD' refer to in machine drafting specifications?

What does the term 'OD' refer to in machine drafting specifications?

What is the primary characteristic of ferrous metals?

What is the primary characteristic of ferrous metals?

What distinguishes malleable iron from regular cast iron?

What distinguishes malleable iron from regular cast iron?

What is the carbon content of high-carbon steel?

What is the carbon content of high-carbon steel?

Which of the following is an alloy of copper and zinc?

Which of the following is an alloy of copper and zinc?

What is a key property of aluminum compared to steel?

What is a key property of aluminum compared to steel?

Flashcards are hidden until you start studying

Study Notes

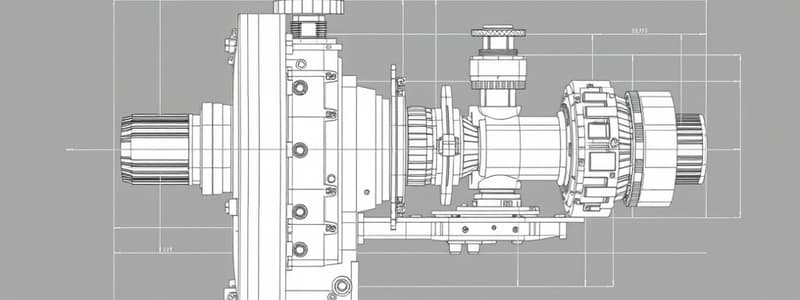

Introduction to Machine Drawing

- Machine drafting specializes in creating technical drawings of machine parts and components.

- Orthographic views are used to depict size and shape accurately.

- Familiarity with terminologies enhances understanding in machine drawings.

Abbreviations and Symbols in Machine Drafting

- Key abbreviations include A/F (across flats), Alum (aluminum), ASTM (American Society for Testing Materials), and DWG (drawing).

- Symbols represent specific attributes like CPL (cutting plane line), OD (outside diameter), and RAD (radius).

Elements of Mechanical Manufacturing

- Importance of manufacturing processes in representing a part's features accurately.

- Understanding the part's intended use enhances the effectiveness of the drawing.

Production Materials

- Material selection is essential based on characteristics such as availability, cost, workability, stability, and machinability.

- Key considerations include weight, wear resistance, corrosion resistance, and strength.

Common Metals Used in Mechanical Manufacturing

-

Ferrous Metals: Contain iron and have magnetic properties; includes pig iron, cast iron, and steel.

- Pig iron is the base for producing all types of iron and steel.

- Cast iron is preferred for casting parts; examples include engine blocks and parts requiring durability.

- Malleable iron has refined structures for improved toughness.

-

Non-Ferrous Metals: Do not contain iron, are typically non-magnetic, and corrosion-resistant.

- Brass: Alloy of copper and zinc; easy to machine and cast.

- Bronze: Alloy of copper and tin; used for bearing applications.

- Aluminum: Lightweight, extracted from bauxite; alloyed for strength and flexibility.

Primary Production Processes

-

Processes that give parts their basic shapes include machining, casting, forging, stamping, and welding.

-

Machining: Material is cut into desired shape and size, often using lathes for cylindrical shapes.

-

Casting: Liquid material is poured into molds to solidify; includes sand casting and die casting.

-

Forging: Metal is shaped by force; includes cold and hot forming for increased strength.

-

Stamping: Shaping flat sheet-metal by pressing through dies.

-

Welding: Joining metals by melting and cooling; provides high strength and is ideal for small parts.

Secondary Shop Processes

-

Secondary processes refine parts after primary shaping to meet specific dimensions outlined in drawings.

-

Drilling: Creates cylindrical holes for fitments; accuracy is variable.

-

Reaming: Finishes drilled holes to precise dimensions.

-

Boring: Enlarges existing holes.

-

Counterbore: Enlarges a hole to a required depth for a flush fitting.

-

Spotface: Provides a machined area over a hole, typically on rough surfaces.

-

Countersink: Bevels the edge of a hole for tapered shoulder accommodation.

-

Knurling: Creates a textured surface for improved grip; can be varied by pattern.

-

Chamfer: Beveled edges that eliminate sharpness on handled parts, enhancing safety.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.