Podcast

Questions and Answers

What is the role of carbonaceous materials during cyanidation?

What is the role of carbonaceous materials during cyanidation?

- They act as a preg-robber. (correct)

- They enhance gold leaching.

- They are reducing agents.

- They are oxidizing agents.

What is the main pyrometallurgical technique mentioned?

What is the main pyrometallurgical technique mentioned?

- Roasting (correct)

- Chlorine oxidation

- Pressure leaching

- Bacterial oxidation

At what temperature range does pressure leaching occur?

At what temperature range does pressure leaching occur?

- Over 350 °C

- 100 - 160 °C

- 160 - 350 °C (correct)

- 50 - 100 °C

What happens to sulphide ores during pressure leaching?

What happens to sulphide ores during pressure leaching?

Which of the following is not a hydrometallurgical oxidation process?

Which of the following is not a hydrometallurgical oxidation process?

Which element is oxidized to arsenate during the leaching process?

Which element is oxidized to arsenate during the leaching process?

Which reaction corresponds to the oxidation of iron (II) to ferric in the leaching process?

Which reaction corresponds to the oxidation of iron (II) to ferric in the leaching process?

What is a consequence of the pre-treatment process in cyanidation?

What is a consequence of the pre-treatment process in cyanidation?

What temperature is considered excessive for the roasting process?

What temperature is considered excessive for the roasting process?

Why is pressure leaching not widely practiced in Ghana?

Why is pressure leaching not widely practiced in Ghana?

Study Notes

Course Aims and Objectives

- Aim: Prepare students to become competent mining engineers with essential knowledge in extractive metallurgy processes.

- Objectives include:

- Educating on extractive metallurgy principles.

- Introducing various branches and processes involved.

- Encouraging practical application of knowledge in their engineering careers.

Expected Outcomes

- Gain a strong understanding of extractive metallurgy.

- Apply principles learned in practical scenarios as both students and professional engineers.

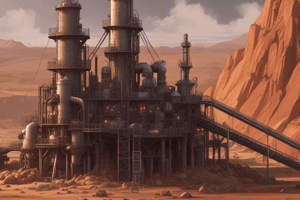

Pyrometallurgy Overview

- Pyrometallurgy: Thermal treatment of minerals and ores for recovering valuable metals through physical and chemical transformations.

- Saleable products include pure metals, intermediate compounds, or alloys.

Processes in Pyrometallurgy

- Processes include:

- Drying

- Calcining

- Roasting

- Smelting

- Refining

- Energy input is crucial, often sourced from combustion of fuels or electric heat.

Fluidized Bed Roaster (FBR)

- FBR facilitates multiphase reactions by passing gas or liquid through granular solids.

- Fluidization enhances reactivity and efficiency in industrial applications.

Blast Roasting

- Multi hearth roaster relies on natural draft air circulation.

- In blast roasting, air is forced through the stationary charge, with limestone addition to control temperature.

- Roasters can process 10,000 tons daily, but the Dwight-Lloyd process has largely replaced it, termed Sinter Roasting.

Factors for Well-Roasted Products

- Particle size: Should be small for optimal reaction rates without over-grinding.

- Ore should be porous to enhance mineral dissolution and extraction.

Heap Leaching Advantages and Characteristics

- Cost-effective method with minimal filtration and low operator intervention.

- Retention time allows for repeated cycles but has lower recovery rates (70-80%).

- Heaps can reach significant heights (up to 50m).

Leach Pad Design

- Ground preparation includes compacting, grading, and a uniform impermeable layer.

- Cells within the pad provide independent drainage systems for effective management.

Gold Properties Relevant to Extractive Metallurgy

- Melting point: 1064 °C; Boiling point: 2808 °C; Density: 19.3; Atomic weight: 196.967.

- Important compounds include chlorides and cyanides.

- Gold's solubility and ability to form amalgams with mercury are crucial for recovery.

Classification of Gold Ores in Ghana

- Types of gold ores: alluvial, free milling, and refractory.

- Alluvial ores contain naturally liberated gold recoverable by gravity concentration without milling.

- Free milling ores allow up to 95% gold recovery via direct cyanidation.

Pre-Treatment Processes for Ores

- Pre-treatment aims to reduce gangue mineral interference and enhance leaching effectiveness.

- Methods include pyrometallurgical oxidation (e.g., roasting) and hydrometallurgical oxidation (e.g., pressure leaching).

Pressure Leaching Process

- Conducted at high temperatures (160-350 °C) and under pressure, leading to dissolution of sulphide ores.

- Relatively expensive and not widely practiced in Ghana.

Roasting Techniques

- Involves thermal decomposition of sulphides and carbonaceous materials at temperatures exceeding 600 °C, enhancing metal recovery.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Related Documents

Description

This quiz explores the foundational concepts of extractive metallurgy, crucial for aspiring mining engineers. Students will learn about the various branches and processes that define the field. It aims to equip students with the knowledge they need to succeed in mineral processing.