Podcast

Questions and Answers

Which factor is NOT typically considered when selecting insulation materials for electrical machines?

Which factor is NOT typically considered when selecting insulation materials for electrical machines?

- Voltage rating

- Temperature tolerance

- Magnetic permeability (correct)

- Chemical resistance

What is the primary purpose of implementing quality control measures during the fabrication of machines?

What is the primary purpose of implementing quality control measures during the fabrication of machines?

- To comply with environmental regulations

- To reduce manufacturing costs

- To ensure the machine's reliability and performance (correct)

- To enhance performance under specific load conditions

Which of the following methods is NOT a typical fabrication technique used in manufacturing electrical machines?

Which of the following methods is NOT a typical fabrication technique used in manufacturing electrical machines?

- Casting

- Injection molding (correct)

- Winding

- Stamping

In the context of performance analysis, which aspect is NOT concerned with minimizing losses in electrical machines?

In the context of performance analysis, which aspect is NOT concerned with minimizing losses in electrical machines?

Which consideration is essential for ensuring machines meet international safety standards?

Which consideration is essential for ensuring machines meet international safety standards?

What is the initial step in the electrical machine design process?

What is the initial step in the electrical machine design process?

Which machine type is typically chosen based on application requirements?

Which machine type is typically chosen based on application requirements?

What aspect of design focuses on preventing damage to electrical machines due to mechanical stresses?

What aspect of design focuses on preventing damage to electrical machines due to mechanical stresses?

What is a significant consideration when designing the electrical components of a machine?

What is a significant consideration when designing the electrical components of a machine?

Which design consideration focuses on minimizing losses due to magnetic materials?

Which design consideration focuses on minimizing losses due to magnetic materials?

During which design phase are precise calculations for magnetic flux and current flow conducted?

During which design phase are precise calculations for magnetic flux and current flow conducted?

In the context of electrical machine design, why is cooling system design critical?

In the context of electrical machine design, why is cooling system design critical?

What is a common objective during the optimization step of the electrical machine design?

What is a common objective during the optimization step of the electrical machine design?

Flashcards

Magnetic Material Selection

Magnetic Material Selection

Choosing silicon steel or other materials based on their magnetic properties, like permeability and saturation flux density.

Electrical Conductor Selection

Electrical Conductor Selection

Selecting copper, aluminum, or other materials based on how much current they can carry and their cost.

Insulation Material Selection

Insulation Material Selection

Picking insulation materials that can withstand the machine's voltage, temperature, and any chemicals they might encounter.

Efficiency Analysis

Efficiency Analysis

Signup and view all the flashcards

Losses Minimization

Losses Minimization

Signup and view all the flashcards

Electrical Machine Design

Electrical Machine Design

Signup and view all the flashcards

Defining Requirements

Defining Requirements

Signup and view all the flashcards

Determining Machine Type

Determining Machine Type

Signup and view all the flashcards

Preliminary Design

Preliminary Design

Signup and view all the flashcards

Detailed Design

Detailed Design

Signup and view all the flashcards

Optimization

Optimization

Signup and view all the flashcards

Electrical Design

Electrical Design

Signup and view all the flashcards

Mechanical Design

Mechanical Design

Signup and view all the flashcards

Study Notes

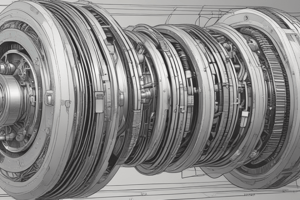

Introduction to Electrical Machine Design

- Electrical machine design creates efficient and reliable machines (generators, motors, transformers).

- Key factors include performance, materials, manufacturing, and cost-effectiveness.

Design Steps and Considerations

- Defining the Requirements: Design starts by specifying intended use, output power, voltage, speed, efficiency, and environmental conditions.

- Determining the Machine Type: Choosing the appropriate machine type (synchronous, induction, DC) based on the application.

- Preliminary Design: Estimating dimensions, materials, and parameters (poles, windings).

- Detailed Design: Precise calculations of magnetic flux, current flow, and mechanical stresses.

- Optimization: Continuously adjusting design for better performance, efficiency, and cost.

- Manufacturing: Considering fabrication methods, tolerances, and quality control for cost-effectiveness and reliability.

Key Design Parameters

- Magnetic Design:

- Determining magnetic flux density for sufficient strength and minimized losses.

- Optimizing core material (e.g., silicon steel) and geometry.

- Reducing core losses (hysteresis, eddy current).

- Electrical Design:

- Designing windings (type, configuration) matching electrical needs and reducing losses (copper).

- Calculating conductor current carrying capacity and insulation system properties.

- Ensuring insulation thermal stability and breakdown strength.

- Mechanical Design:

- Determining stable, rigid mechanical structure with adequate cooling.

- Calculating stresses to avoid damage or failure.

- Selecting appropriate shaft materials, bearings, and other mechanical components for expected life and loads.

- Cooling System Design:

- Designing cooling systems (air, liquid) to manage heat dissipation and maintain temperature.

- Control Systems:

- Designing control systems to monitor and regulate operation.

- Ensuring correct voltage, speed, and torque response.

- Implementing protection against faults and overloads.

Material Selection

- Magnetic Materials: Choosing silicon steel or suitable materials based on permeability and saturation flux density.

- Electrical Conductors: Selecting copper, aluminum, or other materials based on current capacity and cost.

- Insulation Materials: Choosing insulation based on voltage rating, temperature tolerance, and chemical resistance.

- Structural Materials: Choosing materials to meet the strength requirements for supporting components.

Manufacturing Considerations

- Fabrication Methods: Selecting appropriate manufacturing methods (stamping, casting, winding) for cost and efficiency.

- Quality Control: Implementing quality control measures for reliability and performance.

Performance Analysis

- Efficiency: Evaluating efficiency under various operating conditions.

- Losses: Identifying and minimizing electrical, magnetic, and mechanical losses.

- Temperature Rise: Calculating and controlling temperature rise in all machine parts.

- Thermal Management: Ensuring adequate cooling to maintain safe operating temperatures.

- Dynamic Response: Analyzing machine response to changes in load and other conditions.

Ethical Considerations

- Designing and implementing machines that meet safety standards and environmental regulations.

- Minimizing environmental impact through resource efficiency and sustainable materials.

Advanced Topics (Examples)

- Finite Element Analysis (FEA) for detailed magnetic field analysis.

- Optimization techniques to improve design performance.

- Design for manufacturing (DFM) principles.

- Condition monitoring and predictive maintenance.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.