Podcast

Questions and Answers

Quel paramètre décrit le rapport entre la puissance de sortie et la puissance d'entrée d'une pompe centrifuge ?

Quel paramètre décrit le rapport entre la puissance de sortie et la puissance d'entrée d'une pompe centrifuge ?

- Hauteur

- Cavitation

- Rendement (correct)

- Débit

Quelle classification de pompe centrifuge concerne les fluides qui s'écoulent principalement dans la direction d'axe du rotor ?

Quelle classification de pompe centrifuge concerne les fluides qui s'écoulent principalement dans la direction d'axe du rotor ?

- Pompe à diaphragme

- Pompe à débit radial

- Pompe à débit axial (correct)

- Pompe à débit mixte

Quel est le principal inconvénient des pompes centrifuges lorsqu'elles fonctionnent avec des fluides de haute viscosité ?

Quel est le principal inconvénient des pompes centrifuges lorsqu'elles fonctionnent avec des fluides de haute viscosité ?

- Elles peuvent subir une cavitation (correct)

- Elles ne peuvent pas augmenter la pression

- Elles sont très coûteuses

- Elles n'ont pas de capacité de démarrage

Quel est l'effet de la vitesse de la pompe sur le rendement global de la pompe centrifuge ?

Quel est l'effet de la vitesse de la pompe sur le rendement global de la pompe centrifuge ?

Quel terme décrit la pression minimale requise à l'entrée de la pompe centrifuge pour éviter la cavitation ?

Quel terme décrit la pression minimale requise à l'entrée de la pompe centrifuge pour éviter la cavitation ?

Quelle application est typiquement réalisée par des pompes centrifuges ?

Quelle application est typiquement réalisée par des pompes centrifuges ?

Comment la construction des pompes centrifuges se compare-t-elle avec celle des pompes à piston ?

Comment la construction des pompes centrifuges se compare-t-elle avec celle des pompes à piston ?

Quel phénomène destructeur est causé par des bulles de vapeur qui se forment et éclatent dans les pompes centrifuges ?

Quel phénomène destructeur est causé par des bulles de vapeur qui se forment et éclatent dans les pompes centrifuges ?

Quelles sont les caractéristiques des pompes volumétriques rotatives ?

Quelles sont les caractéristiques des pompes volumétriques rotatives ?

Quel est le principe de fonctionnement de la pompe à palette rigide ?

Quel est le principe de fonctionnement de la pompe à palette rigide ?

Quelle est la principale différence entre les pompes à vis et les pompes à piston plongeur ?

Quelle est la principale différence entre les pompes à vis et les pompes à piston plongeur ?

Quels types de fluides les pompes centrifuges peuvent-elles traiter efficacement ?

Quels types de fluides les pompes centrifuges peuvent-elles traiter efficacement ?

Quel est un aspect clé du débit des pompes à engrenage ?

Quel est un aspect clé du débit des pompes à engrenage ?

Quelle caractéristique d'une pompe est directement liée à l'énergie nécessaire pour vaincre les pertes de charge par frottement ?

Quelle caractéristique d'une pompe est directement liée à l'énergie nécessaire pour vaincre les pertes de charge par frottement ?

Quel facteur influence le rendement d'une pompe centrifuge en fonction du débit ?

Quel facteur influence le rendement d'une pompe centrifuge en fonction du débit ?

Quelle limitation est spécifique aux pompes centrifuges par rapport aux pompes volumétriques ?

Quelle limitation est spécifique aux pompes centrifuges par rapport aux pompes volumétriques ?

Quel énoncé décrit correctement la fonction d'aspiration d'une pompe centrifuge dans un circuit ?

Quel énoncé décrit correctement la fonction d'aspiration d'une pompe centrifuge dans un circuit ?

Quel est le lien entre la vitesse de rotation de la pompe et l'énergie cinétique du fluide ?

Quel est le lien entre la vitesse de rotation de la pompe et l'énergie cinétique du fluide ?

Quel terme définit la pression minimale requise à l'entrée d'une pompe centrifuge pour éviter un phénomène destructeur ?

Quel terme définit la pression minimale requise à l'entrée d'une pompe centrifuge pour éviter un phénomène destructeur ?

Qu'est-ce qui influence principalement la hauteur manométrique totale d'une pompe ?

Qu'est-ce qui influence principalement la hauteur manométrique totale d'une pompe ?

Quel est le type de pompe le plus adapté pour utiliser des fluides à faible viscosité ?

Quel est le type de pompe le plus adapté pour utiliser des fluides à faible viscosité ?

La puissance d'une pompe centrifuge dépend principalement de quel facteur ?

La puissance d'une pompe centrifuge dépend principalement de quel facteur ?

Quelle propriété d'une pompe centrifuge est généralement supérieure à celle des pompes volumétriques ?

Quelle propriété d'une pompe centrifuge est généralement supérieure à celle des pompes volumétriques ?

Flashcards

Pompe centrifuge

Pompe centrifuge

Une pompe dynamique qui utilise une roue à aubes rotative pour augmenter la pression d'un fluide.

Principe de fonctionnement

Principe de fonctionnement

Le fluide entre au centre de la roue à aubes, est accéléré, et la force centrifuge augmente la pression du fluide à mesure qu'il se déplace vers l'extérieur.

Débit

Débit

Le volume de fluide pompé par unité de temps.

Hauteur manométrique

Hauteur manométrique

Signup and view all the flashcards

Cavitation

Cavitation

Signup and view all the flashcards

NPSH

NPSH

Signup and view all the flashcards

Classification des pompes centrifuges

Classification des pompes centrifuges

Signup and view all the flashcards

Efficacité

Efficacité

Signup and view all the flashcards

Pompe volumétrique rotative

Pompe volumétrique rotative

Signup and view all the flashcards

Engrenage

Engrenage

Signup and view all the flashcards

Pompe à palette

Pompe à palette

Signup and view all the flashcards

Pompe à vis

Pompe à vis

Signup and view all the flashcards

Quelle est la pression qui est atteinte au centre de la roue?

Quelle est la pression qui est atteinte au centre de la roue?

Signup and view all the flashcards

Que se passe-t-il au fluide lorsqu'il se déplace vers la périphérie de la roue ?

Que se passe-t-il au fluide lorsqu'il se déplace vers la périphérie de la roue ?

Signup and view all the flashcards

Avantages des pompes centrifuges

Avantages des pompes centrifuges

Signup and view all the flashcards

Inconvénients des pompes centrifuges

Inconvénients des pompes centrifuges

Signup and view all the flashcards

HMT

HMT

Signup and view all the flashcards

Pression différentielle

Pression différentielle

Signup and view all the flashcards

Qu'est-ce que la HMT représente ?

Qu'est-ce que la HMT représente ?

Signup and view all the flashcards

Comment la HMT est-elle calculée ?

Comment la HMT est-elle calculée ?

Signup and view all the flashcards

Study Notes

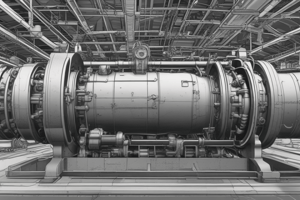

Introduction to Centrifugal Pumps

- Centrifugal pumps are a type of dynamic pump that use a rotating impeller to increase the pressure of a fluid.

Operation Principle

- Fluid enters the pump impeller at the center, where it is accelerated by the rotating impeller blades.

- The centrifugal force generated by the impeller increases the pressure of the fluid as it moves outwards.

- The increased pressure causes the fluid to exit the pump at a higher velocity and pressure than its inlet.

- Key components include the impeller, casing, and motor.

Classification of Centrifugal Pumps

- Based on the shape of the impeller, pumps can be classified as:

- Radial flow

- Mixed flow

- Axial flow pumps.

Important Parameters

- Head: The pressure increase produced by the pump, often expressed in meters of liquid column.

- Flow rate: The volume of fluid pumped per unit of time (e.g., cubic meters per hour).

- Efficiency: The ratio of output power to input power, expressing how effectively the pump converts input energy into fluid energy.

- NPSH (Net Positive Suction Head): The required minimum pressure at the suction side of the pump to prevent cavitation.

- Pump speed: The rate of rotation of the impeller.

Applications

- Centrifugal pumps have a vast array of applications across many industries.

- Common uses include water supply, irrigation, industrial processing, and chemical handling.

Advantages

- Relatively simple construction and design.

- Ability to handle large flow rates.

- High efficiency for many applications.

- Often cost-effective, especially for larger flow rates.

- Easy to start, stop and maintain (compared to reciprocating pumps).

Disadvantages

- May not operate well in highly viscous fluids.

- Dependent on the suction head, and can be prone to cavitation in applications with low suction pressures.

- Potential for noise and vibrations.

Cavitation

- Cavitation is an undesirable phenomenon that can occur in pumps and turbines.

- It occurs in the low-pressure, high-velocity region of the pump, where the pressure drops below the vapor pressure of the liquid.

- This can lead to the formation of vapor bubbles that collapse violently, creating erosion and damage to the pump components.

- The NPSH is crucial in preventing this phenomenon.

Selection Criteria

- The selection of a centrifugal pump depends on specific application needs.

- Considerations include flow rate, head requirements, type of fluid, and operating conditions.

Maintenance and Troubleshooting

- Regular maintenance is crucial to ensure optimal pump performance and prevent premature failure.

- Monitoring key parameters like flow rate, pressure, and efficiency can help detect issues early.

- Troubleshooting involves identifying the root cause of any pump malfunction or performance deviation.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.