Podcast

Questions and Answers

What is the primary reason a frequency converter is used with induction motors?

What is the primary reason a frequency converter is used with induction motors?

- To allow for accurate speed control (correct)

- To enhance motor efficiency significantly

- To reverse the direction of rotation

- To reduce the motor's torque requirements

How can the direction of rotation of a three-phase motor be reversed?

How can the direction of rotation of a three-phase motor be reversed?

- By changing the rotor's magnetic field

- By increasing the voltage supply

- By adjusting the motor's frequency

- By reversing any two phases (correct)

Which method cannot be used to achieve variable speed in an induction motor?

Which method cannot be used to achieve variable speed in an induction motor?

- Using a fixed capacitor (correct)

- Using a Variable Speed Drive (VSD)

- Employing separate windings for different speeds

- Using a frequency converter

What must be considered when reversing a split-phase motor's rotation direction?

What must be considered when reversing a split-phase motor's rotation direction?

What impact does the shading ring have on a motor?

What impact does the shading ring have on a motor?

How does the load affect the speed of an induction motor's rotor?

How does the load affect the speed of an induction motor's rotor?

What is the relationship between slip and motor load?

What is the relationship between slip and motor load?

What happens to the rotor speed when the load on an induction motor increases?

What happens to the rotor speed when the load on an induction motor increases?

What is one advantage of a wound rotor in an induction motor?

What is one advantage of a wound rotor in an induction motor?

What happens if the load on a synchronous motor exceeds the pull-out torque?

What happens if the load on a synchronous motor exceeds the pull-out torque?

In a synchronous motor, what is the relationship between the rotor pole and stator pole at no-load?

In a synchronous motor, what is the relationship between the rotor pole and stator pole at no-load?

What common synchronous speeds are expected for 50-hertz motors?

What common synchronous speeds are expected for 50-hertz motors?

What is the relationship between the speed of the rotor and the stator field in an induction motor?

What is the relationship between the speed of the rotor and the stator field in an induction motor?

How does the phase voltage in a star-wound stator winding compare to a delta-wound stator winding?

How does the phase voltage in a star-wound stator winding compare to a delta-wound stator winding?

What is the effect of the rotor reaching synchronous speed in an induction motor?

What is the effect of the rotor reaching synchronous speed in an induction motor?

What effect does varying physical design features of a rotor have?

What effect does varying physical design features of a rotor have?

In a squirrel-cage rotor, what is a key characteristic regarding insulation?

In a squirrel-cage rotor, what is a key characteristic regarding insulation?

Why do induction motors require only a slight change in speed to produce usual current changes?

Why do induction motors require only a slight change in speed to produce usual current changes?

What is the purpose of a star-delta arrangement in starting large three-phase induction motors?

What is the purpose of a star-delta arrangement in starting large three-phase induction motors?

What does Lenz's law state regarding the magnetic field in a single-phase induction motor?

What does Lenz's law state regarding the magnetic field in a single-phase induction motor?

What is indicated by a low rotor-induced EMF in relation to the torque of an induction motor?

What is indicated by a low rotor-induced EMF in relation to the torque of an induction motor?

What condition must be met for relative motion to exist in an induction motor?

What condition must be met for relative motion to exist in an induction motor?

What happens if the resistance in a wound rotor is set to an open circuit?

What happens if the resistance in a wound rotor is set to an open circuit?

What occurs to line current when switching from a star connection to a delta connection?

What occurs to line current when switching from a star connection to a delta connection?

How does the rotor's turning force relate to load on an induction motor?

How does the rotor's turning force relate to load on an induction motor?

What does 'slip' refer to in an induction motor?

What does 'slip' refer to in an induction motor?

In single-phase AC induction motors, how does the stator magnetic field behave?

In single-phase AC induction motors, how does the stator magnetic field behave?

What limits the torque in a star-wound stator compared to a delta-wound stator?

What limits the torque in a star-wound stator compared to a delta-wound stator?

Which of the following is true about a squirrel-cage rotor's design?

Which of the following is true about a squirrel-cage rotor's design?

What initiates the rotation of the rotor in a synchronous motor?

What initiates the rotation of the rotor in a synchronous motor?

What is required to fully lock the rotor in step with the stator field?

What is required to fully lock the rotor in step with the stator field?

Which of the following describes the pull-out torque of a synchronous motor?

Which of the following describes the pull-out torque of a synchronous motor?

What type of construction is commonly found in the rotor of a synchronous motor?

What type of construction is commonly found in the rotor of a synchronous motor?

What is the primary disadvantage of a salient pole rotor in synchronous motors?

What is the primary disadvantage of a salient pole rotor in synchronous motors?

How does the rotor of a synchronous motor maintain speed regardless of load variations?

How does the rotor of a synchronous motor maintain speed regardless of load variations?

What function does a centrifugal switch serve in a synchronous motor?

What function does a centrifugal switch serve in a synchronous motor?

Which principle explains the operation of a synchronous motor?

Which principle explains the operation of a synchronous motor?

What happens when the rotor of a single-phase induction motor is rotated by an outside force?

What happens when the rotor of a single-phase induction motor is rotated by an outside force?

Which starting method is the most common for single-phase AC induction motors?

Which starting method is the most common for single-phase AC induction motors?

In a capacitor-start split-phase motor, what is the purpose of the capacitor in the starting winding?

In a capacitor-start split-phase motor, what is the purpose of the capacitor in the starting winding?

What occurs to the starting winding once the motor reaches 75% of its rated speed?

What occurs to the starting winding once the motor reaches 75% of its rated speed?

How does the current behave in the starting winding of a capacitor-start motor?

How does the current behave in the starting winding of a capacitor-start motor?

How are the currents in the main and auxiliary windings of a capacitor-start induction motor related?

How are the currents in the main and auxiliary windings of a capacitor-start induction motor related?

What role does the starting switch play in a capacitor-start split-phase motor?

What role does the starting switch play in a capacitor-start split-phase motor?

What is the primary function of the start winding in single-phase induction motors?

What is the primary function of the start winding in single-phase induction motors?

Flashcards

Shading Ring

Shading Ring

A conductive ring placed on one pole face of a split-phase motor that creates a small starting torque by shifting the magnetic field slightly.

Frequency Converter

Frequency Converter

A device used to control the speed of AC induction motors by changing the frequency of the electrical power supplied to the motor.

Variable Speed Drive (VSD)

Variable Speed Drive (VSD)

An alternative term for a frequency converter, often used in industrial settings.

Reversing a Split-Phase Motor's Direction

Reversing a Split-Phase Motor's Direction

Signup and view all the flashcards

Split-Phase Motor Limitations

Split-Phase Motor Limitations

Signup and view all the flashcards

Synchronous Motor Rotor

Synchronous Motor Rotor

Signup and view all the flashcards

Squirrel Cage Winding

Squirrel Cage Winding

Signup and view all the flashcards

How does a Synchronous Motor Start?

How does a Synchronous Motor Start?

Signup and view all the flashcards

Synchronous Motor - Rotor Field

Synchronous Motor - Rotor Field

Signup and view all the flashcards

Salient Poles

Salient Poles

Signup and view all the flashcards

Synchronous Motor – DC Excitation

Synchronous Motor – DC Excitation

Signup and view all the flashcards

Synchronous Motor – Principle of Operation

Synchronous Motor – Principle of Operation

Signup and view all the flashcards

Pull-out Torque

Pull-out Torque

Signup and view all the flashcards

Squirrel-cage rotor

Squirrel-cage rotor

Signup and view all the flashcards

Wound rotor

Wound rotor

Signup and view all the flashcards

Induction motor

Induction motor

Signup and view all the flashcards

Lenz's Law

Lenz's Law

Signup and view all the flashcards

Slip

Slip

Signup and view all the flashcards

Starting torque

Starting torque

Signup and view all the flashcards

Synchronous speed

Synchronous speed

Signup and view all the flashcards

Single-Phase Induction Motor

Single-Phase Induction Motor

Signup and view all the flashcards

Split-Phase Induction Motor

Split-Phase Induction Motor

Signup and view all the flashcards

Capacitor-Start Split Phase

Capacitor-Start Split Phase

Signup and view all the flashcards

Main Winding

Main Winding

Signup and view all the flashcards

Starting Winding (Auxiliary)

Starting Winding (Auxiliary)

Signup and view all the flashcards

Phase Difference

Phase Difference

Signup and view all the flashcards

Magnetic Field

Magnetic Field

Signup and view all the flashcards

Induction Motor Speed

Induction Motor Speed

Signup and view all the flashcards

Induction Motor Torque and EMF

Induction Motor Torque and EMF

Signup and view all the flashcards

Induction Motor Slip

Induction Motor Slip

Signup and view all the flashcards

Slip and Induction Motor Current

Slip and Induction Motor Current

Signup and view all the flashcards

Induction Motor Constant Speed Operation

Induction Motor Constant Speed Operation

Signup and view all the flashcards

Synchronous Speed of Induction Motors

Synchronous Speed of Induction Motors

Signup and view all the flashcards

Rotor Speed vs. Synchronous Speed

Rotor Speed vs. Synchronous Speed

Signup and view all the flashcards

Induction Motor Torque Development

Induction Motor Torque Development

Signup and view all the flashcards

What is pull-out torque?

What is pull-out torque?

Signup and view all the flashcards

Explain the rotor field of a synchronous motor.

Explain the rotor field of a synchronous motor.

Signup and view all the flashcards

Why is star winding preferred for starting in synchronous motors?

Why is star winding preferred for starting in synchronous motors?

Signup and view all the flashcards

What is the purpose of salient poles in a synchronous motor?

What is the purpose of salient poles in a synchronous motor?

Signup and view all the flashcards

What is the key difference between synchronous and induction motor operation?

What is the key difference between synchronous and induction motor operation?

Signup and view all the flashcards

What is the torque angle in a synchronous motor?

What is the torque angle in a synchronous motor?

Signup and view all the flashcards

Explain the stator of a synchronous motor.

Explain the stator of a synchronous motor.

Signup and view all the flashcards

Study Notes

AC Motor Fundamentals

- AC motors are widely available and lower in cost than DC motors

- Maintenance is lower as most AC motors do not use brushes and commutators

- Eliminates the problem of dangerous sparking

- Well-suited for constant-speed applications

- Speed is determined by the frequency of the AC voltage applied to the motor

- Motors can be designed for polyphase or single-phase power

Types of AC Motors

-

Induction motors:

- Most commonly used AC motor

- Can use single-phase or polyphase

- Rotors are energised by induction

-

Synchronous motors:

- Typically polyphase

- Constant speed

- Rotors energised by DC voltage

Three-Phase Rotating Fields

- Individual windings are present for each phase

- Three phases are connected in a Y-connected stator, with the dot indicating the common point

- Individual phase windings are evenly spaced around the stator, 120° apart

- Left-hand rule should be employed to determine the electromagnetic polarity of the poles at any instant

- Current flows toward the terminals for positive voltages and away for negative voltages

- Strong magnetic field is aided by weaker field

- When three phases complete a full cycle, the magnetic field rotates through 360°

Speeds of AC Motors

-

The magnetic field's speed in an AC motor is related to the supply frequency

-

Field rotation speed is known as synchronous speed (Ns)

-

Rotational speed of an AC motor shaft is related to Ns

-

Synchronous speed (Ns) is determined using the formula: Ns = (Freq x 120) / P

- F = Frequency of AC power (Hz)

- P = Number of poles per phase wound into the motor

- Ns = Synchronous speed (rpm)

-

Some AC motors operate nearly at synchronous speed, termed synchronous motors

-

Asynchronous motors operate at a speed less than synchronous speed, and are also known as induction motors

-

Percentage difference between full-load speed and synchronous speed is known as slip

-

Normal slip is around 5% but may be higher

Induction Motor

- Probably the simplest and most rugged of all electric motors

- Most commonly used type of AC motor

- Rotor is not connected to an external voltage source

- AC voltages are induced in the rotor circuit by the rotating magnetic field of the stator

- Similar to the induction between primary and secondary windings of a transformer, typically used to drive loads at fairly constant speed

- Only two main components– the stator and the rotor

Induction Motor - Stator

- Consists of a pattern of copper coils arranged in windings

- When AC is passed through windings, a rotating magnetic field is formed

- This induces a current in the rotor, creating its own magnetic field

- Interaction of these fields produces a torque on the rotor

- No direct electrical connection between stator and rotor

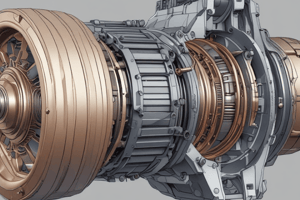

Induction Motor - Rotor

- Typically made of a laminated cylinder with slots in its surface

- Two types of rotors commonly used for induction motors: squirrel-cage rotor and wound rotor

- Squirrel-cage rotor, most common type, which has actual wound coils placed in rotor slots

- Wound rotor rotor, other type, which contains actual wound coils

Squirrel-Cage Rotor

- Number of conducting bars running parallel to the motor axis

- Two conducting end rings

- Conductors typically copper or aluminium, although aluminium is often used in smaller motors

- Resembles a squirrel cage; thus the name

Induction Motor - Slanted Rotor

- Slanting conductors in the rotor ensures a smooth steady acceleration during starting

- Varying the physical design features of the rotor can:

- Increase their inductance

- Give a lower starting current

- Create a lower pull-out torque

Squirrel-Cage Rotor (Specifics)

- No insulation between the core and bars as only low voltages are induced into rotor bars

- Very small air gap between rotor and stator is necessary to obtain maximum field strength

Wound Rotor

- Typically only needs to be used during starting when starting requirements are particularly severe

- Advantages:

- Starting torque can be adjusted

- Speed of the motor can be controlled

- Has three windings and three slip rings

- Adjustments made by simultaneously varying three resistors (externally connected)

- Open circuit resistances and motor will not run

- Resistances vary, thus varying torque and speed

Induction Motor (Specifics)

- Lenz's law – any induced EMF tries to oppose the changing field that induces it

- In an induction motor, the changing field is the motion of the resultant stator field

- A force is exerted on the rotor by the induced EMF and the resultant magnetic field

- Force tends to cancel the relative motion between the rotor and the stator field

- Rotor, as a result, moves in the same direction as the rotating stator field

- Induction motor cannot run at synchronous speed

- If speeds are the same, there would be no relative motion between the stator and rotor fields

- Without relative motion, there would be no induced voltage in the rotor

Induction Motor (Specifics - cont.)

- Speed of the rotor depends upon the torque requirements of the load

- The bigger the load, the stronger the turning force needed to rotate the rotor

- Turning force can increase only if the rotor-induced EMF increases

- EMF can increase only if the magnetic field cuts through the rotor at a faster rate

- To increase relative speed between field and rotor, the rotor must slow down

- Induction motor turns slower for heavier loads than lighter loads

Induction Motor (Specifics - cont.)

- Slip is directly proportional to load on the motor

Induction Motors – Slip

- Common synchronous speeds for 50-hertz motors are: 3000, 1500, 1000, and 750 rpm, depending on the number of poles (2, 4, 6, 8) per phase

- Common terminology – for example, a two-pole motor (three Ø) has six physical poles

- Rotor is never able to reach synchronous speed; without the speed, there would be no torque

- Typically, the difference between these two speeds is not great

Induction Motors – Slip (Formula)

- S% = (Ns - N) / Ns x 100

- S% = percentage slip

- Ns = synchronous speed

- N = rotor speed

Synchronous Motor

- Characteristic of constant speed between no load and full load

- May be designed either single-phase or multiphase

- Single-phase also spins at synchronous speed

- Discussion below is based on three-phase synchronous motors

Synchronous Motor (Specifics)

- Three-phase AC power to the stator causes a rotating magnetic field to be set up around the rotor

- Rotor is energised with DC (acts like a bar magnet)

- Strong rotating magnetic field attracts strong rotor field activated by DC

- Results in a strong turning force on the rotor shaft

- Rotor therefore rotates in step with the rotating magnetic field– synchronous speed

Synchronous Motor (Additional Details)

- Disadvantages

- Cannot be started from a standstill

- Have no starting torque

- Rotating field quickly passes rotor poles

- Rotor has no chance to get started

Synchronous Motor – Rotor

- Squirrel-cage winding is added to rotor of a synchronous motor for starting

- Simply, the windings are heavy copper bars shorted together by copper rings

- A low voltage is induced in these shorted windings by rotating stator field

- Because of the short circuit, a relatively large current flows in the squirrel cage

- This causes a magnetic field that interacts with the rotating field of the stator

- Interaction causes rotor to turn; following the stator field, the motor begins rotating

- Squirrel-cage rotors will be covered in more detail shortly

Synchronous Motor – Rotor (cont.)

- To start synchronous motor

- AC supplied to stator, but DC is NOT YET supplied to rotor field

- Squirrel-cage windings bring rotor to near synchronous speed

- DC field in rotor is energised at this point

- This locks rotor in step with rotating stator field and full torque is developed

- Centrifugal switch is used to apply DC to rotor at sufficient speed

Synchronous Motor – Rotor (cont.)

- Rotor, typically constructed with salient poles

- When excited with DC – produces alternating north and south magnetic poles

- These magnetic poles on rotor outer are attracted in rotating stator field

- Disadvantage– requires a DC exciter voltage for the rotor

- DC may be obtained either externally or internally, depending on the design of the motor

Synchronous Motor – Operation

- Principle of magnetic attraction between two magnetic fields of opposite polarity - One field is that of the rotating stator, and the other is from the rotor

- No-load

- Centre lines of stator pole of rotating field and rotor pole coincide

- With load

- Backward shift of rotor pole, relative to stator pole; no change in speed

- Angle between rotor and stator poles is called the torque angle

Synchronous Motor - Additional Details

- Operates at synchronous speed with no slip

- Rotor has constant polarity (either permanent magnet or energised electromagnet)

- Will run at the speed regardless of load variations up to a point called the pull-out torque

- Pull-out torque – maximum value of torque a motor can develop without losing synchronism

- A load higher than this will pull the motor out of synchronism and cause it to stop

- Stator is basically the same as an induction motor stator

Synchronous Motor - Additional Details (cont.)

- Star wound stator winding will draw less current than a delta wound type

- Common to use a 'star-delta' arrangement for starting larger, three-phase induction motors

- This limits starting current on initial start

- At approx. 75% speed, switches over to 'delta'

- In Star, the voltage is reduced to 58% (or 240V for 415V)

- In Delta, phase voltage increases by 173% as does current, which results in increased torque

- Line current (in delta) increases 3 times its value in star connection

Single-Phase Induction Motors

- Probably more single-phase AC induction motors in use today than any other type

- Unlike polyphase induction motors, the stator field in a single-phase AC motor does not rotate

- Instead, it simply alternates polarity between poles as the AC changes polarity

Single-Phase Induction Motors (cont.)

- As a result of magnetic induction, a magnetic field is produced around the rotor

- This field will always be in opposition to the stator field (Lenz's law applies)

- If the rotor is rotated by an outside force, the push-pull along the line is disturbed

- At this instant, south pole on the rotor is attracted to the left-hand pole — north to RH pole

- All of this is a result of the rotor being rotated 90° by an outside force

- The pull that now exists between the two fields becomes a rotary force

- This further turns the rotor toward magnetic correspondence with the stator

- Because two fields continuously alternate, they will never actually line up

- Rotor will continue to turn once started

Single-Phase Induction Motors (Additional Details)

- Several types of single-phase AC induction motors in use today

- They operate in the same fashion, except for the means of starting

- Once up to operating speed, all single-phase AC induction motors operate similarly

- Various methods used for starting single-phase AC induction motors:

- Split-phase

- Shaded-pole

Split-Phase AC Induction Motor

- One type of induction motor which incorporates a starting device.

- Designed to use inductance, capacitance, or resistance to develop starting torque

- Typically, the start winding is disconnected after the motor reaches 75% of its rated speed

Capacitor-Start Split-Phase

- Stator consists of main winding and a starting winding (auxiliary)

- Start winding is parallel with the main winding and is placed physically at right angles to it

- A 90-degree electrical phase difference between the two windings is obtained by connecting the auxiliary winding in series with a capacitor and starting switch

- In the start winding circuit, current leads voltage by about 45°

- In the main winding, current lags voltage by about 45°—thus, current in the each winding is 90° out of phase, and likewise, the magnetic fields

Capacitor-Start Split-Phase (cont.)

- Effect is that the two windings act like a two-phase stator and produce the rotating field required for start

- At 75% speed, a centrifugal device (starting switch) removes the start winding

- Motor then runs as a plain single-phase induction motor.

Permanent-Split Capacitor Motor

- Capacitor of this motor is left in series with the start winding during normal operation

- Starting torque is low, approximately 40% of full load

- Used on low-inertia loads, such as fans and blowers

Permanent-Split Capacitor Motor (cont.)

- Another type of split-phase induction motor—the resistance-start motor

- Start winding positioned at right angles to the main winding

- Start winding is switched in and out of the circuit (75%) as in the capacitor-start motor

- Electrical phase shift between currents in two windings is obtained by making impedance of windings unequal

- Main winding has high inductance and low resistance (I lags V by a large angle)

- Start winding has low inductance and high resistance (I lags V by a smaller angle)

- Starting torque is not as great as compared to a capacitor-start motor

Shaded-Pole Induction Motor

- First effort in developing a self-starting, single-phase motor

- Has field poles that extend inward from motor housing

- A portion of each pole is encircled with a heavy copper ring

- Copper ring causes the magnetic field through the ring portion of the pole face to lag appreciably behind that of the other half of the pole

- Results in slight rotation in the field, which is strong enough to cause rotation

- Torque created is small; but enough to start but not efficient overall

- Reverse direction by placing shading ring on the other pole face

Speed Control

- Induction motors are practically fixed-speed devices

- Two methods available to change the rotation speed:

- Using a frequency converter (VSD or Variable Speed Drive)

- Using a motor with separate windings for different speeds

- Frequency converters are utilized where accurate speed control is needed

- Frequency converters work well with three-phase AC induction motors but not with single-phase AC induction motors

Direction of Rotation – Three-Phase

- Direction of rotation depends upon the direction of the rotating field

- Reversing the direction is achieved by reversing any two phases

Reversing a Split-Phase Motor

- With some split-phase motors, a switch can select the direction of rotation

- Phase b to lag a, or b to lead a, thus causes the motor to follow the leading current

- Only available on some single-phase motors

- Many motors' start and run windings are physically different

- Centrifugal switch must also be considered, if used

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.