Podcast

Questions and Answers

What is the primary purpose of laminating the iron core in a transformer?

What is the primary purpose of laminating the iron core in a transformer?

- To reduce hysteresis losses

- To increase the turns ratio

- To minimize eddy current losses (correct)

- To improve insulation

What is the function of the Buchholz relay in a transformer?

What is the function of the Buchholz relay in a transformer?

- To adjust the turns ratio

- To insulate the windings

- To cool the transformer

- To monitor gas and oil levels (correct)

What is the purpose of the tap changer in a transformer?

What is the purpose of the tap changer in a transformer?

- To adjust the output voltage (correct)

- To improve insulation

- To increase the efficiency of the transformer

- To reduce hysteresis losses

What type of rotor is commonly used in induction motors?

What type of rotor is commonly used in induction motors?

What is the purpose of the bearings in an induction motor?

What is the purpose of the bearings in an induction motor?

What is the function of the windings in a transformer?

What is the function of the windings in a transformer?

What is the main purpose of incorporating predictive maintenance features in electrical machine design?

What is the main purpose of incorporating predictive maintenance features in electrical machine design?

Which of the following materials is NOT a common conductor in electrical engineering?

Which of the following materials is NOT a common conductor in electrical engineering?

What is the primary application of Gallium Arsenide (GaAs) in electronic devices?

What is the primary application of Gallium Arsenide (GaAs) in electronic devices?

Which of the following materials is used in the construction of photo detectors and light-emitting diodes (LEDs)?

Which of the following materials is used in the construction of photo detectors and light-emitting diodes (LEDs)?

What is the primary function of Thermal Interface Materials (TIM) in electronic devices?

What is the primary function of Thermal Interface Materials (TIM) in electronic devices?

What is the primary application of FR-4 (Flame Retardant 4) in electrical engineering?

What is the primary application of FR-4 (Flame Retardant 4) in electrical engineering?

What is the primary purpose of the end bells and housing in an induction motor?

What is the primary purpose of the end bells and housing in an induction motor?

Which of the following is a major consideration in electrical machine design?

Which of the following is a major consideration in electrical machine design?

What is the primary function of the terminal box in an induction motor?

What is the primary function of the terminal box in an induction motor?

Which of the following is a thermal consideration in electrical machine design?

Which of the following is a thermal consideration in electrical machine design?

What is the primary purpose of the nameplate on an induction motor?

What is the primary purpose of the nameplate on an induction motor?

Which of the following is a consideration in electrical machine design to ensure efficiency and minimize losses?

Which of the following is a consideration in electrical machine design to ensure efficiency and minimize losses?

What is the primary application of fiberglass composites?

What is the primary application of fiberglass composites?

Which of the following benefits is provided by Computer-Aided Design (CAD)?

Which of the following benefits is provided by Computer-Aided Design (CAD)?

What is the primary advantage of using CAD software for product simulation and analysis?

What is the primary advantage of using CAD software for product simulation and analysis?

What is the primary benefit of using CAD models for manufacturing?

What is the primary benefit of using CAD models for manufacturing?

What is the primary advantage of using CAD software for design iteration?

What is the primary advantage of using CAD software for design iteration?

What is the primary benefit of using Computer-Aided Design (CAD) in product development?

What is the primary benefit of using Computer-Aided Design (CAD) in product development?

What is the primary purpose of Finite Element Analysis (FEA) in CAD?

What is the primary purpose of Finite Element Analysis (FEA) in CAD?

What is the purpose of Computational Fluid Dynamics (CFD) in CAD?

What is the purpose of Computational Fluid Dynamics (CFD) in CAD?

What is the purpose of Thermal Analysis in CAD?

What is the purpose of Thermal Analysis in CAD?

What is the purpose of Kinematic Analysis in CAD?

What is the purpose of Kinematic Analysis in CAD?

What is Parametric Modeling in CAD?

What is Parametric Modeling in CAD?

What is the benefit of integrating analysis tools with CAD software?

What is the benefit of integrating analysis tools with CAD software?

What type of analysis evaluates how a design reacts to forces?

What type of analysis evaluates how a design reacts to forces?

Which CAD modeling technique integrates features with parametric constraints?

Which CAD modeling technique integrates features with parametric constraints?

What is the primary goal of Multidisciplinary Design Optimization (MDO)?

What is the primary goal of Multidisciplinary Design Optimization (MDO)?

What is the primary function of Virtual Prototyping?

What is the primary function of Virtual Prototyping?

What is the primary benefit of Cloud-Based CAD?

What is the primary benefit of Cloud-Based CAD?

What is the primary goal of Generative Design?

What is the primary goal of Generative Design?

What is the primary function of Knowledge-Based Engineering (KBE)?

What is the primary function of Knowledge-Based Engineering (KBE)?

What type of analysis studies motion without considering forces?

What type of analysis studies motion without considering forces?

What is the primary benefit of CAD/CAE Integration?

What is the primary benefit of CAD/CAE Integration?

What is the primary benefit of Hybrid Methods in CAD?

What is the primary benefit of Hybrid Methods in CAD?

Flashcards are hidden until you start studying

Study Notes

Transformer Constructional Features

- Transformers have a laminated iron core to minimize eddy current losses

- The core is constructed from thin laminations coated to reduce hysteresis losses and improve efficiency

- Transformers have primary and secondary windings made of copper or aluminum wire, insulated to prevent short circuits

- The turns ratio between primary and secondary windings determines the voltage transformation

- Insulation is crucial to prevent electrical breakdown between the windings and the core

- Transformers are often enclosed in a tank filled with oil for cooling and insulation

- Cooling systems include natural convection, forced air, or oil circulation systems

- Some transformers have a tap changer to adjust the turns ratio and output voltage

- Large transformers may include a Buchholz relay to detect internal faults by monitoring gas and oil levels

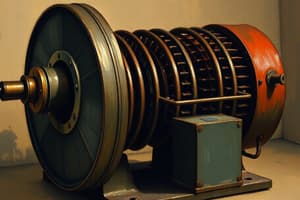

Induction Motor Constructional Features

- The stator consists of a laminated iron core with three-phase windings

- The windings are evenly spaced to create a rotating magnetic field when powered

- Induction motors have either a squirrel-cage rotor or a wound rotor

- The squirrel-cage rotor is a cylindrical laminated core with conductive bars embedded in the slots

- Bearings support the rotor and allow it to rotate within the stator

- End bells and housing protect the motor and provide environmental protection

- Cooling systems include natural convection, forced air, or liquid cooling

- The terminal box contains the connection points for the motor leads

- The nameplate provides important information such as voltage, current, power factor, speed, and other specifications

- Larger motors may include a fan to enhance cooling

Electrical Machine Design Considerations

- Application requirements: understanding load characteristics, environmental conditions, and machine type and size

- Electromagnetic design: core material selection, magnetic circuit design, and winding design

- Thermal considerations: heat dissipation, temperature rise, and cooling mechanisms

- Mechanical design: structural integrity, rotor and stator construction, and mechanical stresses

- Efficiency and losses: core losses, copper losses, and material selection

- Manufacturability and cost: material cost, ease of manufacturing, and assembly

- Control and regulation: control system compatibility, regulation, and compliance

- Reliability and maintenance: predictive maintenance features and serviceability

- Noise and vibration: noise reduction and vibration control

- Size and weight constraints: compact design and weight optimization

Electrical Engineering Materials

- Conductors: copper, aluminum, and silver

- Insulators: polymer insulators, ceramics, and porcelain

- Semiconductors: silicon, germanium, and gallium arsenide

- Superconductors: niobium-titanium, niobium-tin, and high-temperature superconductors

- Dielectric materials: ceramic capacitors, polymer capacitors, and high-k dielectrics

- Magnetic materials: ferrites, alnico, and rare-earth magnets

- Optoelectronic materials: gallium arsenide, indium phosphide, and silicon

- Thermal materials: thermal interface materials, copper, and aluminum

- Composite materials: fiberglass composites, carbon nanotube composites, and other composite materials

Need for CAD

- Design efficiency: speed and accuracy in design creation and modification

- Accuracy and precision: measurement control and geometric relationships

- Visualization: realistic 3D visualizations for design understanding and communication

- Product simulation and analysis: stress analysis, thermal analysis, and other simulations

- Collaboration and communication: multi-user collaboration and version control

- Documentation and standards compliance: accurate documentation and regulatory compliance

- Cost reduction: reduction of errors and rework

- Prototyping and manufacturing: generation of physical prototypes and manufacturing tool paths

- Design iteration: easy modification and iteration of designs

- Time-to-market acceleration: faster design iterations and product development

Analysis Methods of CAD

- Finite element analysis (FEA): structural integrity and behavior under various conditions

- Computational fluid dynamics (CFD): fluid flow patterns, temperature distributions, and other fluid behaviors

- Mechanical stress analysis: stress and strain distribution under various loads

- Thermal analysis: heat transfer and temperature distribution

- Kinematic analysis: motion of mechanical components and interference analysis

- Optimization analysis: refinement of designs to meet specific criteria

- Electromagnetic analysis: electromagnetic field interactions with designs

Synthesis and Hybrid Methods of CAD

- Geometric modeling: wireframe, surface, and solid modeling

- Parametric modeling: parametric constraints and feature-based modeling

- Finite element analysis (FEA): structural, thermal, and fluid dynamics analysis

- Assembly modeling: top-down and bottom-up assembly modeling

- Kinematic and dynamic analysis: motion and force analysis

- Hybrid methods: feature-based and parametric modeling, surface and solid modeling, CAD/CAM integration, and CAD/CAE integration

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.