Podcast

Questions and Answers

Oil from a hydraulic circuit such as the pilot hydraulic system is used to boost the master cylinder's force when the ______ are applied.

Oil from a hydraulic circuit such as the pilot hydraulic system is used to boost the master cylinder's force when the ______ are applied.

brakes

A hydraulic pump is used to supply oil to the boosted ______, via the pilot accumulator.

A hydraulic pump is used to supply oil to the boosted ______, via the pilot accumulator.

master cylinder

The service brake pedals control the brake master ______, which send oil under pressure to the brake pistons.

The service brake pedals control the brake master ______, which send oil under pressure to the brake pistons.

cylinders

This example shows a brake hydraulic system with a boosted master cylinder and two service brake ______.

This example shows a brake hydraulic system with a boosted master cylinder and two service brake ______.

Some machines are equipped with a hydraulic boosted brake system to obtain increased ______ force with less effort.

Some machines are equipped with a hydraulic boosted brake system to obtain increased ______ force with less effort.

The service brake pedals (1) send oil under pressure to the brake pistons located in the rear ______.

The service brake pedals (1) send oil under pressure to the brake pistons located in the rear ______.

Hydraulic force multiplies the pedal ______ so the operator can brake with less effort.

Hydraulic force multiplies the pedal ______ so the operator can brake with less effort.

Caterpillar's hydraulic brake system utilizes the pilot ______ to enhance functionality.

Caterpillar's hydraulic brake system utilizes the pilot ______ to enhance functionality.

The combination valve operates similarly to the charging valve but replaces it with a ______ valve.

The combination valve operates similarly to the charging valve but replaces it with a ______ valve.

The priority valve directs oil flow from the pump to the brake ______ or another hydraulic system.

The priority valve directs oil flow from the pump to the brake ______ or another hydraulic system.

In the combination valve system, the oil flow into the valve is regulated by the ______ valve.

In the combination valve system, the oil flow into the valve is regulated by the ______ valve.

The combination valve is part of the hydraulic brake systems in the Motor ______.

The combination valve is part of the hydraulic brake systems in the Motor ______.

The pump feeds hydraulic oil into the combination ______.

The pump feeds hydraulic oil into the combination ______.

Another hydraulic system that may receive oil flow from the priority valve is the fan ______.

Another hydraulic system that may receive oil flow from the priority valve is the fan ______.

The relief valve is labeled as ______ in the combination valve diagram.

The relief valve is labeled as ______ in the combination valve diagram.

The combination valve ensures that the brake hydraulic system has oil ______ over other systems.

The combination valve ensures that the brake hydraulic system has oil ______ over other systems.

Step 1 is to verify the customer's ______.

Step 1 is to verify the customer's ______.

Step 2 involves conducting an initial ______.

Step 2 involves conducting an initial ______.

In Step 3, you should list possible ______.

In Step 3, you should list possible ______.

The main focus will be on the Investigate and ______ steps.

The main focus will be on the Investigate and ______ steps.

In Step 4, you analyze possible causes to determine the ______ cause.

In Step 4, you analyze possible causes to determine the ______ cause.

Step 5 involves repairing the ______ cause.

Step 5 involves repairing the ______ cause.

Step 6 is to verify the ______ after repairs.

Step 6 is to verify the ______ after repairs.

In Step 7, all findings are documented in the ______ Report.

In Step 7, all findings are documented in the ______ Report.

The general procedure to check the service brake pressure involves stopping the engine and placing the transmission direction selector in ______.

The general procedure to check the service brake pressure involves stopping the engine and placing the transmission direction selector in ______.

To release all oil pressure from the brake circuit, you must depress the brake ______ repeatedly.

To release all oil pressure from the brake circuit, you must depress the brake ______ repeatedly.

A pressure gauge is installed at the rear service brake pressure ______.

A pressure gauge is installed at the rear service brake pressure ______.

It is important to allow the hydraulic oil to reach normal operating temperature and normal operating ______.

It is important to allow the hydraulic oil to reach normal operating temperature and normal operating ______.

If the brake pressure is not in the correct range but the brake accumulator charging valve is functioning correctly, you should replace the brake control ______.

If the brake pressure is not in the correct range but the brake accumulator charging valve is functioning correctly, you should replace the brake control ______.

The procedure to test the oil pressure at the front service brakes should be repeated at pressure port ______.

The procedure to test the oil pressure at the front service brakes should be repeated at pressure port ______.

Some machines may have a pressure test port near the wheels to check pressure at the inlet to the brake ______.

Some machines may have a pressure test port near the wheels to check pressure at the inlet to the brake ______.

The service brake system discussed is a hydraulic ______ brake system.

The service brake system discussed is a hydraulic ______ brake system.

The cut-in/cut-out spool shifts when the accumulator pressure has reached the ______ pressure.

The cut-in/cut-out spool shifts when the accumulator pressure has reached the ______ pressure.

The priority valve sends excess oil to other hydraulic ______.

The priority valve sends excess oil to other hydraulic ______.

The relief valve limits the ______ pressure in the combination valve circuit.

The relief valve limits the ______ pressure in the combination valve circuit.

The orifice removes pump pressure ______.

The orifice removes pump pressure ______.

The check valve maintains the brake charge ______.

The check valve maintains the brake charge ______.

A pressure switch may be included in the circuit to alert the operator of low ______ pressure.

A pressure switch may be included in the circuit to alert the operator of low ______ pressure.

The brake charging ______ valve is responsible for controlling brake pressure.

The brake charging ______ valve is responsible for controlling brake pressure.

The combination valve provides a link between various hydraulic ______ systems.

The combination valve provides a link between various hydraulic ______ systems.

To perform the accumulator pressure test, first stop the ______.

To perform the accumulator pressure test, first stop the ______.

The accumulator pressure port is located on the accumulator charging ______.

The accumulator pressure port is located on the accumulator charging ______.

While performing the test, one must record the highest pressure reading, which is the accumulator cut-______ pressure.

While performing the test, one must record the highest pressure reading, which is the accumulator cut-______ pressure.

After applying service brakes, the pressure should drop, and the lowest pressure is referred to as the cut-______ pressure.

After applying service brakes, the pressure should drop, and the lowest pressure is referred to as the cut-______ pressure.

If the accumulator pressure readings are not in the correct range, one may need to adjust the accumulator charging ______.

If the accumulator pressure readings are not in the correct range, one may need to adjust the accumulator charging ______.

The adjustment screw can be found on the ______ of the accumulator brake pressure setup.

The adjustment screw can be found on the ______ of the accumulator brake pressure setup.

It is important to engage the parking ______ before beginning the accumulator pressure test.

It is important to engage the parking ______ before beginning the accumulator pressure test.

After stopping the engine, place the transmission direction selector in the ______ position.

After stopping the engine, place the transmission direction selector in the ______ position.

Flashcards

Hydraulic Boosted Brake System

Hydraulic Boosted Brake System

A hydraulic system that uses oil pressure to amplify the force applied by the brake pedal, resulting in stronger braking power.

Boosted Master Cylinder

Boosted Master Cylinder

A key component in a boosted brake system that receives oil pressure from the pilot accumulator and transfers it to the brake master cylinders.

Pilot Accumulator

Pilot Accumulator

A hydraulic component that stores pressurized oil for the boosted master cylinder, ensuring a quick and powerful brake response.

Service Brake Pedals

Service Brake Pedals

Signup and view all the flashcards

Brake Master Cylinders

Brake Master Cylinders

Signup and view all the flashcards

Rear Axle

Rear Axle

Signup and view all the flashcards

Pilot Hydraulic System

Pilot Hydraulic System

Signup and view all the flashcards

Hydraulic Pump

Hydraulic Pump

Signup and view all the flashcards

Combination valve in Motor Graders (MG)

Combination valve in Motor Graders (MG)

Signup and view all the flashcards

Priority Valve (MG)

Priority Valve (MG)

Signup and view all the flashcards

Brake accumulator (MG)

Brake accumulator (MG)

Signup and view all the flashcards

Check valve (MG)

Check valve (MG)

Signup and view all the flashcards

Relief valve (MG)

Relief valve (MG)

Signup and view all the flashcards

Orifice (MG)

Orifice (MG)

Signup and view all the flashcards

Pressure switch (MG)

Pressure switch (MG)

Signup and view all the flashcards

Cut-in/cut-out spool (MG)

Cut-in/cut-out spool (MG)

Signup and view all the flashcards

Combination Valve

Combination Valve

Signup and view all the flashcards

Cut-in/Cut-out Spool

Cut-in/Cut-out Spool

Signup and view all the flashcards

Brake Accumulator

Brake Accumulator

Signup and view all the flashcards

Relief Valve

Relief Valve

Signup and view all the flashcards

Orifice

Orifice

Signup and view all the flashcards

Check Valve

Check Valve

Signup and view all the flashcards

Pressure Switch

Pressure Switch

Signup and view all the flashcards

Solenoid Valve

Solenoid Valve

Signup and view all the flashcards

Service Brake Pressure Test

Service Brake Pressure Test

Signup and view all the flashcards

Service Brake Pressure Test Port

Service Brake Pressure Test Port

Signup and view all the flashcards

Hydraulic Accumulator Brake System

Hydraulic Accumulator Brake System

Signup and view all the flashcards

Brake Accumulator Charging Valve

Brake Accumulator Charging Valve

Signup and view all the flashcards

Brake Control Valve

Brake Control Valve

Signup and view all the flashcards

Depress Brake Pedal Repeatedly

Depress Brake Pedal Repeatedly

Signup and view all the flashcards

Normal Operating Temperature

Normal Operating Temperature

Signup and view all the flashcards

Accumulator

Accumulator

Signup and view all the flashcards

Accumulator Charging Valve

Accumulator Charging Valve

Signup and view all the flashcards

Cut-in Pressure

Cut-in Pressure

Signup and view all the flashcards

Cut-out Pressure

Cut-out Pressure

Signup and view all the flashcards

Accumulator Pressure (Cut-in/Cut-out) Test

Accumulator Pressure (Cut-in/Cut-out) Test

Signup and view all the flashcards

Accumulator Brake Pressure Adjustment

Accumulator Brake Pressure Adjustment

Signup and view all the flashcards

Adjustment Screw

Adjustment Screw

Signup and view all the flashcards

Digital Pressure Indicator Group Tool

Digital Pressure Indicator Group Tool

Signup and view all the flashcards

Caterpillar 7-Step Diagnostic Process

Caterpillar 7-Step Diagnostic Process

Signup and view all the flashcards

Step 1: Verify Customer Concern

Step 1: Verify Customer Concern

Signup and view all the flashcards

Step 2: Conduct Initial Inspection

Step 2: Conduct Initial Inspection

Signup and view all the flashcards

Step 3: List Possible Causes

Step 3: List Possible Causes

Signup and view all the flashcards

Step 4: Analyze Possible Causes and Determine Root Cause

Step 4: Analyze Possible Causes and Determine Root Cause

Signup and view all the flashcards

Step 5: Repair Root Cause

Step 5: Repair Root Cause

Signup and view all the flashcards

Step 6: Verify the Repair

Step 6: Verify the Repair

Signup and view all the flashcards

Step 7: Document Concern, Analysis, Repair in Service Report

Step 7: Document Concern, Analysis, Repair in Service Report

Signup and view all the flashcards

Study Notes

Global Dealer Learning: Brake Systems Troubleshooting - Hydraulic Brake Systems

- This module provides information on hydraulic brake system components, operation, testing, and troubleshooting procedures for Caterpillar machines.

- Safety briefing includes emergency phone numbers, first aid responders, location of exits, fire extinguishers, hazard alerts, evacuation location, storm shelter, and hazardous material information.

Purpose

- The module covers hydraulic brake system components, operation, testing, and troubleshooting for machines with hydraulic brakes.

Reason

- Successful completion validates required knowledge, skills, and behaviors for diagnosing and repairing hydraulic brake systems in Caterpillar machines.

Assessment Criteria

- Knowledge assessment: Closed book, minimum passing score of 80%.

- Skills assessment: Competent/Not Yet Competent (determined by instructor observation).

- Instructor observation: Test procedures must be performed correctly.

Learning Outcomes

- Identify hydraulic brake system components.

- Explain hydraulic brake system operation.

- Describe different applications of hydraulic brake systems.

- Describe hydraulic brake system testing and adjusting procedures.

- Describe hydraulic brake system troubleshooting procedures.

- Perform hydraulic brake system testing and adjusting procedures.

Cat 7-Step Diagnostic Process

- Investigate: Verify customer concern, conduct initial inspection

- Isolate: List possible causes

- Analyze: Analyze possible causes, determine root cause

- Repair: Repair root cause

- Verify: Verify repair

- Document: Document concern, analysis, repair in service report

Hydraulic Brake Systems Introduction

- Introduction to hydraulic brake systems.

- The Caterpillar 7-Step Diagnostic Process is applied.

- This module offers basic information about hydraulic brake systems.

- Advanced courses will build upon this foundation using a structured method.

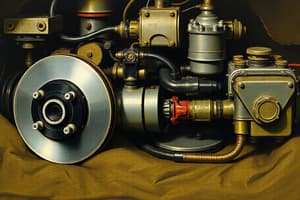

Hydraulic Brake Systems Overview

- Components include Hydraulic Master Cylinder, Hydraulic Boosted Master Cylinder, and Hydraulic Brake Accumulator.

- Master cylinders use oil from a reservoir to apply the brakes. No external oil source is required.

- Hydraulically boosted master cylinders use an external oil source to reduce the pedal effort.

- Hydraulic Accumulators store oil under pressure to use when applied for service brakes.

Master Cylinder (CWL)

- Explains the hydraulic brake system on a compact wheel loader (CWL), without a hydraulic boost.

- The operator's pedal force is transferred, oil is supplied from the reservoir.

- The system sends pressurized oil to the brake piston in the brake caliper.

Master Cylinder (BHL)

- Addresses the hydraulic brake system on a backhoe loader (BHL).

- Left and right brake pedals are controlled by a linkage to a master cylinder.

- The left and right brake pedals can be either used together or separately.

Boosted Master Cylinder Review (BHL)

- Explains hydraulic boosted brake systems on a Backhoe Loader.

- Use of a hydraulic circuit (like a pilot system) to boost the force of the master cylinder.

- Operators can achieve greater braking force with less effort using a hydraulic boost.

Boosted Master Cylinder Operation (BHL)

- Describes the operation of the boosted master cylinder on the backhoe loader.

- Fluid from the pilot hydraulic system boosts the force applied to the master cylinder.

- Spring chambers and components are described, along with the associated process.

Boosted Master Cylinder Operation (CWL) – Brakes Released

- Explains the operation of the boosted master cylinder in a wheel loader with brakes released.

- Oil flows through the system, and the components remain in the neutral position.

Boosted Master Cylinder Operation (CWL) – Brakes Engaged

- Describes the boosted master cylinder operation when the brakes are engaged.

- Servo pistons, plungers, and oil pressure changes are described as the braking system operates.

Boosted Master Cylinder Operation (TH) – Brakes Released

- Discusses boosted master cylinder operation for a telehandler with brakes released.

- The hydraulic accumulator is not pressurized and the system is in neutral.

Boosted Master Cylinder Operation (TH) – Brakes Engaged

- Details the operation when the brakes are engaged, showing the different component interactions using a diagram.

- The hydraulic pump, the servo piston(s) and accumulators become involved.

Hydraulic Accumulator Brake System Review

- Identifies components in a hydraulic accumulator brake system on a 972M wheel loader.

- Describes the role of components in supplying oil for the brake system.

- Explains how the pedal, valve, and accumulators work together to operate the system.

Brake Charging Valve (Cut-In)

- Explains the operation of the brake charging valve on a 988G wheel loader in Cut-In mode.

- The valve controls the oil flow from the accumulators to the hydraulic system.

- Oil pressure in various parts of the system determine valve actions.

Brake Charging Valve (Cut-Out)

- Explains the operation of the brake charging valve on a 988G wheel loader in Cut-Out mode.

- The oil pressure in the accumulators increases, making the valve block oil flow.

Accumulator Charging (LWL)

- Discusses accumulator charging in large wheel loaders (LWL).

- Variable hydraulic pumps and pump servo valves control oil flow to accumulators.

- The control spring, swashplate, and control piston regulate oil flow.

Combination Valve (MG)

- Describes the combination valve operation in motor grader applications.

- The priority valve controls oil flow to the brake accumulators or other hydraulic systems (e.g., fan motor), ensuring oil priority to the brakes.

- The system’s sensors ensure optimal oil pressure.

Combination Valve (MWL)

- Describes operation in medium wheel loaders.

- The ECM controls the charging solenoid valve, which steers oil to the accumulators or other systems.

- Pressure sensors alert the operator of low brake oil pressure.

Systems Testing and Adjusting Overview

- Overview of testing and adjusting procedures for hydraulic brake systems.

- Includes descriptions of different tests for troubleshooting.

Operational Checks: Brake Holding Tests

- Procedures for both service and parking brake holding ability tests.

- These tests determine whether the brakes are operating correctly.

- Key steps in the procedure covered, including engine speed, transmission control, and brake operations.

Brake Accumulator Check: Hydraulic Accumulator Brake Systems

- Explains the general procedure for performing the brake accumulator check.

- Includes descriptions from a hydraulic schematic

Accumulator Pressure

- Explains how to check and charge the brake accumulator.

- Nitrogen usage for proper pressure and stability is described, along with steps to perform this process.

Service Brk Pres Test: Master Cyl Brake Sys

- Describes the general procedure to check service brake pressure on machines with master cylinders.

- Gauge installation and pressure readings are important parts to understanding this testing process.

Service Brk Pres: Hyd Accum Brake System

- Describes the general procedure to check service brake pressure on machines with hydraulic accumulator brake systems.

- Steps for testing the pressure and checking for defects in the system are described.

Accum Pressure (Cut-in/Cut-Out) Test

- Explains the general procedure for the accumulator pressure cut-in/cut-out test.

- The process involves checking the highest and lowest pressures, with the goal of finding any irregularities.

- Includes instructions for using appropriate gauges.

Accumulator Brake Pressure Adjustment

- Explains how to adjust the accumulator pressure.

- Includes using a plug and an adjustment screw.

Parking Brake Pressure

- Explains the general procedure to adjust the parking brake pressure.

- Includes steps for engine start-up and adjusting the pressure to within manufacturer specifications.

System Troubleshooting Overview

- Overview of common troubleshooting processes for hydraulic brake systems.

- It highlights the use of troubleshooting charts to analyze possible causes.

Caterpillar 7-Step Diagnostic Process

- Detailed steps to follow for investigating, isolating, repairing, and documenting a brake issue.

- Describes each step in detail.

Initial Inspection

- Explains the steps to perform a thorough initial inspection of the hydraulic brake system to check for leaks, damage and any problems which could have contributed to the problem.

- Includes diagrams.

Symptom Troubleshooting

- Detailed chart helps establish troubleshooting steps for various scenarios.

- The intent of the troubleshooting chart is to help technicians establish probable causes.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.