Podcast

Questions and Answers

What is the advantage of the single-stage dual-sided impeller?

What is the advantage of the single-stage dual-sided impeller?

- Increased compressor ratio and mass air flow

- Reduced turbulent side air entry

- Reduced impeller diameter (correct)

- Efficient ram recovery

What is the purpose of inlet guide vanes?

What is the purpose of inlet guide vanes?

- To ease the change of airflow from radial to axial direction

- To reduce turbulent side air entry

- To increase compressor ratio

- To induce rotation of the air into the eye of the impeller (correct)

What is a disadvantage of the single-stage dual-sided impeller?

What is a disadvantage of the single-stage dual-sided impeller?

- Inefficient ram recovery (correct)

- Increased compressor ratio

- Reduced impeller diameter

- Efficient airflow direction change

What is a major limitation of centrifugal compressors in larger engines?

What is a major limitation of centrifugal compressors in larger engines?

What replaced the single-stage dual-sided impeller?

What replaced the single-stage dual-sided impeller?

What is an advantage of a centrifugal compressor over an axial compressor?

What is an advantage of a centrifugal compressor over an axial compressor?

What is formed by inclining the front sections of the impeller vanes?

What is formed by inclining the front sections of the impeller vanes?

What is a characteristic of a single-stage centrifugal compressor?

What is a characteristic of a single-stage centrifugal compressor?

What is situated immediately prior to compressor entry when inlet guide vanes are not utilized?

What is situated immediately prior to compressor entry when inlet guide vanes are not utilized?

Why are more than two stages of single entry centrifugal compressors impractical?

Why are more than two stages of single entry centrifugal compressors impractical?

What is a characteristic of some centrifugal flow turboprop engines?

What is a characteristic of some centrifugal flow turboprop engines?

What can be achieved by adding a second compressor stage?

What can be achieved by adding a second compressor stage?

What is the primary purpose of the diffuser in a gas turbine engine?

What is the primary purpose of the diffuser in a gas turbine engine?

What is the point of highest pressure in a gas turbine engine?

What is the point of highest pressure in a gas turbine engine?

What are the two forces that combine to form the angle of attack (AOA) of the compressor blade?

What are the two forces that combine to form the angle of attack (AOA) of the compressor blade?

What occurs when there is an imbalance between the inlet air velocity and compressor rpm?

What occurs when there is an imbalance between the inlet air velocity and compressor rpm?

What is the term used to describe when the entire compressor stalls?

What is the term used to describe when the entire compressor stalls?

What can be done to minimize the chance of an intake-induced stall?

What can be done to minimize the chance of an intake-induced stall?

What is the operating zone between the 'normal operating line' and the 'surge stall line'?

What is the operating zone between the 'normal operating line' and the 'surge stall line'?

What is the point on the operating line where the engine operates during most of its service life?

What is the point on the operating line where the engine operates during most of its service life?

What can occur when a stall or surge causes a momentary stagnation of mass airflow followed by an over-rich condition in the combustor?

What can occur when a stall or surge causes a momentary stagnation of mass airflow followed by an over-rich condition in the combustor?

What is the purpose of a compressor anti-stall bleed system?

What is the purpose of a compressor anti-stall bleed system?

What is the result of compressor efficiency deterioration?

What is the result of compressor efficiency deterioration?

What is the purpose of the compressor surge/stall bleed air valve system?

What is the purpose of the compressor surge/stall bleed air valve system?

What is the primary purpose of the variable stator vane actuating system in a gas turbine engine?

What is the primary purpose of the variable stator vane actuating system in a gas turbine engine?

At low compressor speeds, the variable stator vanes are:

At low compressor speeds, the variable stator vanes are:

What is the result of varying the vane angle in a gas turbine engine?

What is the result of varying the vane angle in a gas turbine engine?

Why do variable stator vanes open as compressor rotor speed increases?

Why do variable stator vanes open as compressor rotor speed increases?

What is the effect of varying vane angles on the airstream in a gas turbine engine?

What is the effect of varying vane angles on the airstream in a gas turbine engine?

What is the benefit of the correct AOA relationship between airflow and rotor blades in a gas turbine engine?

What is the benefit of the correct AOA relationship between airflow and rotor blades in a gas turbine engine?

Flashcards are hidden until you start studying

Study Notes

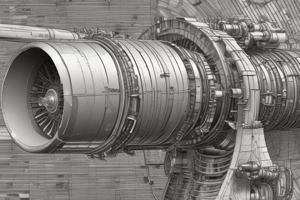

Impeller Types

- Impellers can be single-entry (single-sided) or dual-entry (dual-sided)

- Single-stage dual-sided impeller provides the same compressor ratio and mass air flow with a smaller impeller diameter

- Disadvantages of single-stage dual-sided impeller: turbulent side air entry and inefficient ram recovery

Inlet Guide Vanes

- Impellers incorporate inlet guide vanes called rotating guide vanes or inducers

- Inlet guide vanes induce rotation of the air into the eye of the impeller

- Inlet guide vanes can be formed by inclining the front sections of the impeller vanes to impart a whirl motion in the direction of impeller rotation

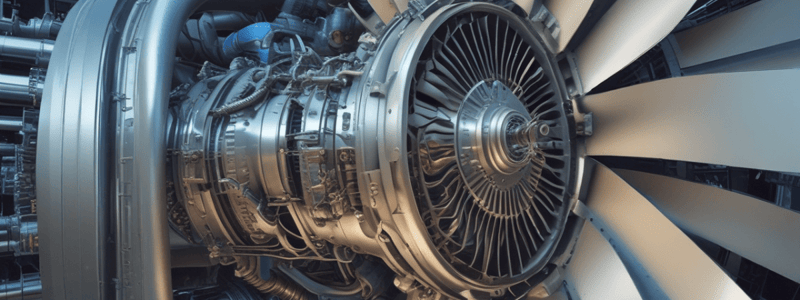

Centrifugal Compressors

- Centrifugal compressors are commonly used in conjunction with axial flow compressors

- Centrifugal compressors are used in smaller flight engines, including turboshaft, turboprop, and turbofan

- Larger engines use axial flow type compressors due to the limitation on mass airflow

- Compressor ratios are about the same for single-sided and dual-sided single-stage impellers

- Ratios as high as 10:1 can be obtained from a single-stage centrifugal compressor

- Compression can be boosted to about 15:1 by a second compressor stage

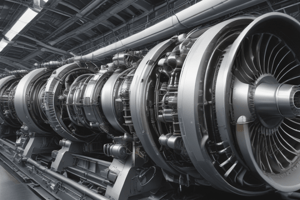

Multistage Centrifugal Compressors

- More than two stages of single entry are impractical due to:

- Airflow energy loss when making the turns from one impeller to the next

- High weight per stage

- High drive power extraction

Centrifugal Compressor Advantages

- Centrifugal compressor is shorter in length than an axial compressor

- Centrifugal compressor has advantages due to its shorter length

Compressor Diffuser

- The diffuser reduces the velocity of the air to prevent the flame in the combustion chamber from being blown out

- The diffuser increases the static pressure of the air, preparing it to enter the combustion area

- The diffuser is known as the point of highest pressure in the gas turbine engine

Compressor Stall and Surge

- Compressor aerofoils experience an infinite variety of AOAs and air densities

- Controlling the AOA is a design function of the inlet duct, the compressor, and the fuel control sensors

- AOA of the compressor blade is the result of inlet air velocity and compressor rpm

- Compressor stall occurs when there is an imbalance between the two vector quantities

- Compressor stall can cause engine damage and a loud audible noise

Anti-Stall Bleed System

- The compressor anti-stall bleed system unloads the compressor by dumping unwanted air during starting and low power operation

- The system restricts the inlet airflow during starting and low power operation

- The system is installed on some gas turbine engines to minimize compressor acceleration and deceleration stall problems at low and intermediate speeds

Variable Vane System

- The variable stator vane actuating system is incorporated on many gas turbine engines

- The system varies the geometry of the compressor gas path to exclude unwanted air and maintain the proper relationship between compressor speed and airflow

- The system is used to minimize compressor acceleration and deceleration stall problems at low and intermediate speeds

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.