Podcast

Questions and Answers

What is a key characteristic of a firetube boiler?

What is a key characteristic of a firetube boiler?

- The boiler is only used for high-pressure applications.

- The products of combustion surround the water and steam.

- The boiler is only used for low-temperature applications.

- The water and steam surround the products of combustion. (correct)

What was a major issue with early firetube boilers?

What was a major issue with early firetube boilers?

- They were too efficient and wasted energy.

- They were too expensive to construct.

- Much heat was passed to brickwork rather than boiler water. (correct)

- They were too large and heavy.

What was an improvement made to early firetube boilers?

What was an improvement made to early firetube boilers?

- Using only riveted construction.

- Decreasing the number of flue gas passes.

- Increasing the size of the boiler.

- Directing combustion gases through firetubes submerged in boiler water. (correct)

What is an advantage of firetube boilers over watertube boilers of comparable rating?

What is an advantage of firetube boilers over watertube boilers of comparable rating?

Why can firetube boilers tolerate lower quality feedwater?

Why can firetube boilers tolerate lower quality feedwater?

What has led to the modern firetube boiler being safer than its early counterparts?

What has led to the modern firetube boiler being safer than its early counterparts?

What is a major disadvantage of firetube boilers?

What is a major disadvantage of firetube boilers?

What is the primary reason locomotive boilers were taken out of service and placed in stationary service?

What is the primary reason locomotive boilers were taken out of service and placed in stationary service?

What is the purpose of staybolts in locomotive boilers?

What is the purpose of staybolts in locomotive boilers?

What is a characteristic of HRT boilers?

What is a characteristic of HRT boilers?

What is the main reason HRT boilers are no longer constructed?

What is the main reason HRT boilers are no longer constructed?

What is the steaming capacity range of HRT boilers?

What is the steaming capacity range of HRT boilers?

What is the main advantage of firetube boilers over watertube boilers?

What is the main advantage of firetube boilers over watertube boilers?

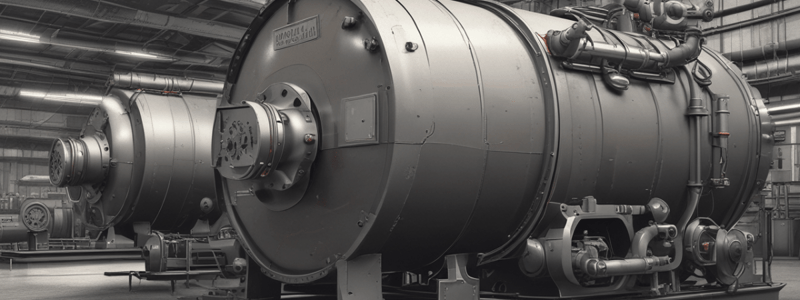

What is the type of boiler shown in Figure 1?

What is the type of boiler shown in Figure 1?

What is the primary application of firebox boilers?

What is the primary application of firebox boilers?

Why are locomotive boilers expensive to construct?

Why are locomotive boilers expensive to construct?

What is the primary advantage of moving the furnace to within the shell of a boiler?

What is the primary advantage of moving the furnace to within the shell of a boiler?

What is the name of the boiler design that is suitable for both high-pressure and low-pressure service?

What is the name of the boiler design that is suitable for both high-pressure and low-pressure service?

What term does ASME use to refer to all types of boilers, regardless of their design?

What term does ASME use to refer to all types of boilers, regardless of their design?

What is the purpose of the reversing chamber in a multi-pass boiler?

What is the purpose of the reversing chamber in a multi-pass boiler?

What is the disadvantage of adding extra passes to a boiler?

What is the disadvantage of adding extra passes to a boiler?

What is the reason for the development of multi-pass boilers?

What is the reason for the development of multi-pass boilers?

What is the term for the pathway through which the products of combustion flow in one direction?

What is the term for the pathway through which the products of combustion flow in one direction?

Why is the Scotch boiler often called a Scotch Marine boiler?

Why is the Scotch boiler often called a Scotch Marine boiler?

What is the purpose of the corrugated furnace in a Scotch boiler?

What is the purpose of the corrugated furnace in a Scotch boiler?

What is the term for the type of Scotch boiler that has a water-cooled surface at the rear of the boiler?

What is the term for the type of Scotch boiler that has a water-cooled surface at the rear of the boiler?

What is a major drawback of modern firetube boilers with multiple passes?

What is a major drawback of modern firetube boilers with multiple passes?

What is the primary heat transfer mechanism in the furnace tube of a two-pass firetube boiler?

What is the primary heat transfer mechanism in the furnace tube of a two-pass firetube boiler?

What is the main advantage of a single-pass firetube boiler?

What is the main advantage of a single-pass firetube boiler?

What is the purpose of the reversing chamber in a two-pass firetube boiler?

What is the purpose of the reversing chamber in a two-pass firetube boiler?

What is the main reason why multiple-pass boilers have more tubes than single-pass boilers?

What is the main reason why multiple-pass boilers have more tubes than single-pass boilers?

What is the main difference between a dry-back and a wet-back three-pass firetube boiler?

What is the main difference between a dry-back and a wet-back three-pass firetube boiler?

Why do multiple-pass boilers require fewer tubes in each pass?

Why do multiple-pass boilers require fewer tubes in each pass?

What is the main advantage of a vertical tubeless boiler?

What is the main advantage of a vertical tubeless boiler?

What is the purpose of the flame retainer rings in a vertical tubeless boiler?

What is the purpose of the flame retainer rings in a vertical tubeless boiler?

What is the main difference between a firetube boiler and a vertical tubeless boiler?

What is the main difference between a firetube boiler and a vertical tubeless boiler?

What is the advantage of using corrugated furnaces?

What is the advantage of using corrugated furnaces?

What is the primary purpose of the flame retainer rings in a firetube boiler?

What is the primary purpose of the flame retainer rings in a firetube boiler?

What is the purpose of staybolts in firetube boilers?

What is the purpose of staybolts in firetube boilers?

What is the function of the fins welded to the outside of the boiler shell?

What is the function of the fins welded to the outside of the boiler shell?

What is the difference between through stays and staybolts?

What is the difference between through stays and staybolts?

What is the maximum allowable working pressure that special designs of firetube boilers can be manufactured to?

What is the maximum allowable working pressure that special designs of firetube boilers can be manufactured to?

What is the primary mechanism of water circulation in firetube boilers in steam service?

What is the primary mechanism of water circulation in firetube boilers in steam service?

What is the purpose of the small hole drilled into the end of through stays and staybolts?

What is the purpose of the small hole drilled into the end of through stays and staybolts?

Where is the lowest permissible water level typically taken in locomotive and firebox boilers?

Where is the lowest permissible water level typically taken in locomotive and firebox boilers?

What is the advantage of using reinforced furnace tubes?

What is the advantage of using reinforced furnace tubes?

What is the purpose of corrugations and reinforcing rings on furnace tubes?

What is the purpose of corrugations and reinforcing rings on furnace tubes?

How are tubes in a firetube boiler typically joined to the tubesheets?

How are tubes in a firetube boiler typically joined to the tubesheets?

What is the typical rating range for vertical tubeless boilers?

What is the typical rating range for vertical tubeless boilers?

What is the purpose of the doors in a firetube boiler?

What is the purpose of the doors in a firetube boiler?

What is the effect of corrugations on furnace turbulence?

What is the effect of corrugations on furnace turbulence?

What is the function of the reversing chamber in a firetube boiler?

What is the function of the reversing chamber in a firetube boiler?

What is the purpose of the inner door and baffle in a firetube boiler with multiple passes?

What is the purpose of the inner door and baffle in a firetube boiler with multiple passes?

What is the consequence of uneven water circulation in firetube boilers?

What is the consequence of uneven water circulation in firetube boilers?

What is the purpose of the tubesheets in a firetube boiler?

What is the purpose of the tubesheets in a firetube boiler?

Why are tubes in a firetube boiler installed differently in each pass?

Why are tubes in a firetube boiler installed differently in each pass?

What was the primary reason for the development of submerged furnace tubes in early firetube boilers?

What was the primary reason for the development of submerged furnace tubes in early firetube boilers?

What is the primary benefit of the large water volume in firetube boilers?

What is the primary benefit of the large water volume in firetube boilers?

Why did design codes become necessary for firetube boilers?

Why did design codes become necessary for firetube boilers?

What is the primary advantage of firetube boilers over watertube boilers of comparable rating?

What is the primary advantage of firetube boilers over watertube boilers of comparable rating?

What led to the improvement in safety of modern firetube boilers compared to their early counterparts?

What led to the improvement in safety of modern firetube boilers compared to their early counterparts?

What was a major issue with early firetube boilers?

What was a major issue with early firetube boilers?

What is the primary reason for the limited operating pressure of firetube boilers?

What is the primary reason for the limited operating pressure of firetube boilers?

What is the main advantage of locomotive boilers in steam locomotives and steam traction engines?

What is the main advantage of locomotive boilers in steam locomotives and steam traction engines?

What is the primary advantage of a single-pass firetube boiler over multi-pass designs?

What is the primary advantage of a single-pass firetube boiler over multi-pass designs?

Why are horizontal return tubular (HRT) boilers no longer constructed?

Why are horizontal return tubular (HRT) boilers no longer constructed?

Why do multiple-pass firetube boilers require more powerful draft fans?

Why do multiple-pass firetube boilers require more powerful draft fans?

What is the purpose of the waterlegs in a locomotive boiler?

What is the purpose of the waterlegs in a locomotive boiler?

What is the primary difference between a dry-back and a wet-back three-pass firetube boiler?

What is the primary difference between a dry-back and a wet-back three-pass firetube boiler?

What is the main difference between a locomotive boiler and a firebox boiler?

What is the main difference between a locomotive boiler and a firebox boiler?

Why do four-pass firetube boilers have fewer tubes in each pass?

Why do four-pass firetube boilers have fewer tubes in each pass?

What is the advantage of using an all-welded construction in modern locomotive boilers?

What is the advantage of using an all-welded construction in modern locomotive boilers?

Why are firetube boilers slow to heat up and bring to operating pressure and temperature?

Why are firetube boilers slow to heat up and bring to operating pressure and temperature?

What is the advantage of a vertical tubeless boiler over other firetube designs?

What is the advantage of a vertical tubeless boiler over other firetube designs?

What is the purpose of the flame retainer rings in a firetube boiler?

What is the purpose of the flame retainer rings in a firetube boiler?

What is the purpose of the radial stays in a locomotive boiler?

What is the purpose of the radial stays in a locomotive boiler?

Why are HRT boilers often retrofitted for gas or oil firing?

Why are HRT boilers often retrofitted for gas or oil firing?

Why are single-pass firetube boilers more economical to maintain?

Why are single-pass firetube boilers more economical to maintain?

What is the primary mechanism of heat transfer in the furnace tube of a two-pass firetube boiler?

What is the primary mechanism of heat transfer in the furnace tube of a two-pass firetube boiler?

What is the primary application of firetube boilers?

What is the primary application of firetube boilers?

What is the consequence of reducing the number of tubes in each pass of a four-pass firetube boiler?

What is the consequence of reducing the number of tubes in each pass of a four-pass firetube boiler?

What is the primary application of vertical tubeless boilers?

What is the primary application of vertical tubeless boilers?

What is the primary reason for moving the furnace within the shell of a boiler?

What is the primary reason for moving the furnace within the shell of a boiler?

What is the main advantage of a multi-pass boiler over a single-pass boiler?

What is the main advantage of a multi-pass boiler over a single-pass boiler?

What is the primary purpose of the reversing chamber in a multi-pass boiler?

What is the primary purpose of the reversing chamber in a multi-pass boiler?

What is the term used to describe the pathway through which the products of combustion flow in one direction?

What is the term used to describe the pathway through which the products of combustion flow in one direction?

What is the main disadvantage of adding extra passes to a boiler?

What is the main disadvantage of adding extra passes to a boiler?

What is the primary advantage of a Scotch boiler over a firebox boiler?

What is the primary advantage of a Scotch boiler over a firebox boiler?

What is the main reason why modern firetube boilers are more efficient than their early counterparts?

What is the main reason why modern firetube boilers are more efficient than their early counterparts?

What is the primary reason why multi-pass boilers require more complex door designs?

What is the primary reason why multi-pass boilers require more complex door designs?

What is the primary advantage of a wet-back boiler over a dry-back boiler?

What is the primary advantage of a wet-back boiler over a dry-back boiler?

What is the primary reason why firetube boilers are more suitable for low-pressure and high-pressure service?

What is the primary reason why firetube boilers are more suitable for low-pressure and high-pressure service?

What is the primary purpose of the fins welded to the outside of the boiler shell?

What is the primary purpose of the fins welded to the outside of the boiler shell?

What is the consequence of poor water circulation in firetube boilers?

What is the consequence of poor water circulation in firetube boilers?

What is the typical lowest permissible water level for locomotive and firebox boilers?

What is the typical lowest permissible water level for locomotive and firebox boilers?

What is the purpose of the tubesheets in a firetube boiler?

What is the purpose of the tubesheets in a firetube boiler?

What is the primary mechanism of water circulation in firetube boilers in hot water service?

What is the primary mechanism of water circulation in firetube boilers in hot water service?

What is the maximum allowable working pressure that special designs of firetube boilers can be manufactured to?

What is the maximum allowable working pressure that special designs of firetube boilers can be manufactured to?

What is the purpose of the reversing chamber in a multi-pass firetube boiler?

What is the purpose of the reversing chamber in a multi-pass firetube boiler?

What is the typical rating range for vertical tubeless boilers?

What is the typical rating range for vertical tubeless boilers?

What is the primary advantage of using corrugated furnaces?

What is the primary advantage of using corrugated furnaces?

What is the term for the type of boiler that is suitable for both high-pressure and low-pressure service?

What is the term for the type of boiler that is suitable for both high-pressure and low-pressure service?

What is the primary benefit of using corrugated furnaces in boilers?

What is the primary benefit of using corrugated furnaces in boilers?

Why are tubes in a firetube boiler installed differently in each pass?

Why are tubes in a firetube boiler installed differently in each pass?

What is the purpose of the small hole drilled into the end of through stays and staybolts?

What is the purpose of the small hole drilled into the end of through stays and staybolts?

What is the primary function of the tubesheets in a firetube boiler?

What is the primary function of the tubesheets in a firetube boiler?

What is the advantage of using ring-reinforced furnaces?

What is the advantage of using ring-reinforced furnaces?

Why are firetubes not reinforced like furnace tubes?

Why are firetubes not reinforced like furnace tubes?

What is the purpose of the doors in a firetube boiler?

What is the purpose of the doors in a firetube boiler?

What is the primary benefit of using diagonal stays in firetube boilers?

What is the primary benefit of using diagonal stays in firetube boilers?

Why are staybolts often attached by welding?

Why are staybolts often attached by welding?

What is the primary purpose of the inner door and baffle in a firetube boiler with multiple passes?

What is the primary purpose of the inner door and baffle in a firetube boiler with multiple passes?

Flashcards are hidden until you start studying

Study Notes

Firetube Boilers

- Advantages:

- Less expensive to purchase than watertube boilers

- Cost less to maintain

- Simpler to maintain and repair

- Have simple, rugged construction

- Can tolerate lower quality feedwater

- Disadvantages:

- Limited to operating pressure of about 2.4 MPa

- Large water volume makes them slow to heat up and bring to operating pressure and temperature

- Take longer to recover from load increases

Locomotive Boilers

- Also known as steam locomotive boilers or steam traction engines

- Can produce up to 45,000 kg/h of superheated steam at 2,400 kPa

- Most were much smaller

- Were either internally fired or externally fired

- Most were riveted designs, but some newer ones are all-welded construction

- Are extensively stayed to support flat surfaces

- Have poor water circulation, are difficult to maintain, and provide poor cleaning and inspection access

Horizontal Return Tubular (HRT) Boilers

- Developed around the same time as locomotive boilers

- Not designed for portability

- Range in steaming capacity from about 500 to 7,000 kg/h, at pressures up to around 1,700 kPa

- Were either top or bottom supported

- Have extensive field-erected brickwork, which requires maintenance and repair

Firebox Boilers

- Are externally fired, two- or three-pass, horizontal firetube boilers

- Most are designed for low-pressure heating service

- Early firetube boilers were very inefficient and unsafe

- Design codes were developed to standardize design calculations and construction methods

- Welding methods progressed, and eventually replaced riveted construction, leading to stronger boilers

Scotch Boilers

- Also known as "Scotch" boilers, "horizontal return tubular" boilers, or "return tubular" boilers

- Designed to maximize heat transfer and increase efficiency

- Suitable for high-pressure and low-pressure service

- Are the predominant style of firetube boiler manufactured today

- Often called "Scotch Marine" boilers

Gas Passes

- One of the advances in boiler technology was to add tubes within the shell of the boiler

- Multi-pass boilers were developed to lengthen the flue gas path without the need for a longer boiler

- Each pass provides more time for heat transfer to occur

- Designs range from one-pass to four-pass, with each additional pass providing more heat transfer

Vertical Tubeless Boilers

- A special two-pass firetube design

- Does not have firetubes, but has a central furnace tube

- Has many advantages, including simplicity, compactness, and automatic controls

- Widely used in dry-cleaning, laundry, and small industrial applications

Firetubes

- Cylindrical steel components subject to external pressure

- Designed like furnace tubes, but not reinforced

- Can be made of welded or seamless tubing

- Tubes can be joined to tubesheets by expanding, welding, or both

Stays

- Support the flat surfaces of the boiler

- Many different styles of stays, including diagonal stays, through stays, and staybolts

- Diagonal stays are used where through stays would block manhole access to the waterside

- Through stays are used where such interference is not a problem

- Staybolts are short through stays, usually attached by welding### Firetube Boilers

- Firetube boilers heat water from the inside of the furnace tube and the outside of the shell.

- They can fire natural gas, propane, or fuel oil.

- Available in ratings from 40 to 600 kW (4 to 60 BoHP).

- Can produce nearly 100% dry and saturated steam at up to 1035 kPa.

- Special designs can be manufactured with maximum allowable working pressures up to 3450 kPa.

- Individually, the largest of these designs can produce up to 940 kg/h of steam.

Water Circulation

- All boilers must be designed to provide adequate water circulation.

- Firetube boilers in steam service rely on circulation caused by natural convection.

- Firetube boilers in hot water service use forced circulation.

- The greatest heat transfer is from radiant furnace heat.

- More steam is produced adjacent to the furnace tube, causing a rise in fluid above the furnace tube and a general settling of fluid adjacent to the shell.

Lowest Permissible Water Level

- All boiler heat transfer surfaces require cooling.

- Boiler tubes are cooled with water.

- Superheater tubes are cooled with steam.

- The lowest permissible water level is usually taken as being 25 mm above the crown sheet for locomotive and firebox boilers.

- For HRT, Scotch marine, and packaged firetube boilers, the lowest permissible water level is usually taken as 25 mm above the top surface of the top row of tubes.

Firetube Boiler Shell

- A complete firetube boiler shell is constructed of courses, heads, furnace tubes, firetubes, stays, and access openings.

- Tubesheets are flat heads with formed edges called flanges.

- Furnace tubes are cylindrical components made of steel, subject to external pressure.

Firetube Boiler Development

- Early firetube boilers were inefficient and unsafe.

- Improvements included submerged furnace tubes and multiple flue gas passes.

- Design codes were developed to standardize design calculations and construction methods.

- Welding methods progressed, and eventually replaced riveted construction, leading to stronger boilers.

Firetube Boiler Advantages

- Simple, rugged construction.

- Contain more water than watertube boilers of a comparable rating, making them quick to respond to load changes.

- Can tolerate lower quality feedwater without disrupting water circulation.

- Less expensive to purchase and maintain than watertube boilers.

- Simpler to maintain and repair than watertube boilers.

Firetube Boiler Disadvantages

-

Limited in operating pressure to about 2.4 MPa.

-

The large water volume makes them slow to heat up and bring to operating pressure and temperature.

-

Take longer to recover from load increases due to the greater volume of water to heat.### Firetube Boilers

-

Modern firetube boilers come in one-, two-, three-, and four-pass designs, which vary in their flue gas paths and heat transfer mechanisms.

-

The relative location of the burner and chimney determines whether the boiler has an even or odd number of passes.

-

The two-pass design is a dry-back, and the three- and four-pass designs are wet-back.

One-Pass Boilers

- One-pass boilers have no central furnace tube, and each firetube is a small-volume furnace, creating more radiant heat transfer surface.

- They have no internal baffles and no refractory, making them more economical to maintain.

- Draft fans can be smaller due to short flue gas travel paths and little furnace pressure drop.

Two-Pass Boilers

- Two-pass firetube boilers have a reversing chamber at the back of the boiler, with primarily radiant heat transfer in the furnace tube and convective heat transfer in the firetubes.

- They are economical to purchase, simple to maintain, and commonly installed.

Three-Pass Boilers

- Three-pass boilers provide greater economy than two-pass designs, with the flue gas traveling a greater distance and having more opportunity to transfer heat to the water.

- They are available as dryback or wetback designs.

Four-Pass Boilers

- Four-pass boilers are considered the most economical design, with the flue gas transferring heat and decreasing in specific volume, resulting in a decrease in flue gas velocity.

- Additional passes must have fewer tubes to maintain proper conditions for combustion.

Vertical Tubeless Boilers

- Vertical tubeless boilers are a special two-pass firetube design with a central furnace tube, but no firetubes.

- They are simple, packaged designs, ready for hook-up with automatic controls, and occupy very little floor space.

- They are widely used in dry-cleaning, laundry, and small industrial applications.

Firebox Boilers

- Modern firebox boilers do not have brick settings, and have minimal refractory, with water-cooled furnaces and usually 3-pass designs.

- They are heavily stayed, difficult to clean, and hard to inspect.

Scotch Boilers

- Scotch boilers were designed to maximize heat transfer and increase efficiency by utilizing the heat that would be otherwise lost through brickwork.

- They are suitable for high-pressure and low-pressure service, and are the predominant style of firetube boiler manufactured today.

- They are also called "Scotch" boilers, "horizontal return tubular" boilers, and "return tubular" boilers.

Gas Passes

- The term "pass" refers to a passageway through which products of combustion flow, in essentially one direction.

- Multi-pass boilers were developed to lengthen the flue gas path without the need for a longer boiler.

- Each additional pass increases heat transfer, but also increases door complexity and refractory requirements.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.