Podcast

Questions and Answers

What is the purpose of factoring hydrant location into apparatus placement?

What is the purpose of factoring hydrant location into apparatus placement?

- To limit the use of hoses at the fire scene

- To enhance the overall appearance of fire trucks

- To save space in front of the building for truck placement (correct)

- To ensure all firefighters stay inside the engine

What happens if the first-due engine cannot spot within hand stretch distance of the hydrant?

What happens if the first-due engine cannot spot within hand stretch distance of the hydrant?

- Water supply completion is deferred to the second-due engine (correct)

- The firefighters retreat and wait for assistance

- It begins a relay operation

- It immediately establishes water supply

What is the role of the second-due pumper's officer upon arrival?

What is the role of the second-due pumper's officer upon arrival?

- To assist the first-due engine with hose deployment

- To conduct an inspection of the fire scene

- To exit the engine and prepare for their assignment (correct)

- To communicate with dispatchers for further instructions

What is typically the attire of the apparatus operator of the second-due pumper?

What is typically the attire of the apparatus operator of the second-due pumper?

What can the apparatus operator of the second-due pumper do if fire flow requirements necessitate it?

What can the apparatus operator of the second-due pumper do if fire flow requirements necessitate it?

Study Notes

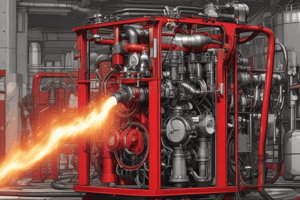

The Engineer

- Engineers must regularly review pump operation skills to perform effectively in emergencies.

- Transition to smaller diameter attack lines and understanding various hose sizes is critical for efficient operation.

- Hose manufacturing advancements have reduced friction coefficients affecting pump operations.

- Simplified calculations are necessary based on feedback from team members.

Pump Discharge Pressure (PDP) Formula

- Total PDP is calculated using the formula: PDP = Nozzle Pressure (NP) + Friction Loss (FL) + Appliances (APPL) + Elevation (ELEV).

- Key variables include:

- NP: The pressure needed at the nozzle.

- FL: Friction loss in the hoseline determined by the coefficient of friction.

- APPL: Pressure loss in appliances used (or gain in some cases).

- ELEV: Elevation adjustments based on height in the setup.

Offensive Operations

- Different nozzles have specific flow rates, typically ranging from 160 GPM to 500 GPM at a nozzle pressure of 50 PSI.

- Friction loss varies per hose size; for example, 1.75” hoselines incur 20-50 PSI loss per 100 feet.

- Understanding and calculating friction loss is essential for determining PDP accurately.

Water Supply Strategies

- Emphasizes immediate water supply through the booster tank to achieve rapid incident control.

- Typical residential fires require 200-300 gallons, highlighting a significant safety buffer with a 1000-gallon booster tank.

Water Supply Plans

- Plan A: First-due engine takes the nearest hydrant within 200 feet for direct water supply establishment.

- Plan B: Reverse lay is utilized if the first engine cannot reach the hydrant, allowing the second engine to establish the supply while the first remains clear for truck access.

Calculation Examples

- Example scenarios provided for various hose configurations and nozzle types to calculate PDP accurately.

- Key figures include elevation impacts of 5 PSI per floor and specific losses based on hose diameters and lengths.

Hydrant Operations

- High-volume hydrant operations are detailed, ensuring adequate water supply for fire suppression.

- Layouts for water shuttle operations such as tender tie-ins and refill protocols improve efficiency in rural settings.

Importance of Fast Water

- Quick access to water is critical for life safety and suppressing fire growth, allowing for aggressive interior firefighting tactics.

- Early deployment of hoselines is crucial for stabilizing situations post-initial engagement.

Miscellaneous

- Various setups such as High-Rise Standpipes and Crosslays are explored, emphasizing importance on nozzle selection and length of hose.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Related Documents

Description

This quiz covers essential knowledge for engineers in firefighting, focusing on pump operation, calculations for pump discharge pressure, and critical hose management skills. Gain insights into the effects of hose diameter and advancements in manufacturing to enhance emergency performance.