Podcast

Questions and Answers

What is the main function of lubrication in an engine?

What is the main function of lubrication in an engine?

To supply engine components with an adequate amount of oil with the correct pressure.

Which of the following are components that must be lubricated? (Select all that apply)

Which of the following are components that must be lubricated? (Select all that apply)

- Crankshaft bearings (correct)

- Oil filter

- Connecting rod bearings (correct)

- Carburetor

What type of lubrication system is most commonly used for four-stroke engines?

What type of lubrication system is most commonly used for four-stroke engines?

- Forced-feed lubrication (correct)

- Dry sump lubrication

- Mixture lubrication

- Total-loss lubrication

What is the working principle of forced-feed lubrication?

What is the working principle of forced-feed lubrication?

Dry sump lubrication is used for small diesel engines.

Dry sump lubrication is used for small diesel engines.

What does an oil pressure gauge do?

What does an oil pressure gauge do?

Which oil pump types are mentioned in the content? (Select all that apply)

Which oil pump types are mentioned in the content? (Select all that apply)

What is the role of an oil filter?

What is the role of an oil filter?

The _______ helps in monitoring the oil pressure and is installed between the oil pump and bearings.

The _______ helps in monitoring the oil pressure and is installed between the oil pump and bearings.

What is one advantage of dry sump lubrication?

What is one advantage of dry sump lubrication?

Which of the following types of engine oil is classified by SAE viscosity grades? (Select all that apply)

Which of the following types of engine oil is classified by SAE viscosity grades? (Select all that apply)

What happens to oil viscosity when the engine is at higher temperatures?

What happens to oil viscosity when the engine is at higher temperatures?

What is the function of a pressure limiting valve?

What is the function of a pressure limiting valve?

Engine oil additives are used to enhance the oil's properties.

Engine oil additives are used to enhance the oil's properties.

Flashcards are hidden until you start studying

Study Notes

Lubricating System Functions

- Lubrication ensures adequate oil supply to engine components, maintaining correct pressure.

- Reduces friction, energy losses, and wear between moving parts.

- Cools engine parts to prevent overheating, as they cannot dissipate heat directly.

- Seals moving parts for precision fit, such as piston rings against cylinder walls.

- Cleans by removing debris, deposits, and combustion residues, rendering them harmless.

- Provides corrosion protection and dampens engine noise and vibrations.

Lubrication Points

- Key engine components needing lubrication include:

- Crankshaft, connecting rod, and gudgeon pin bearings

- Tappets, camshaft bearings, and cam tracks

- Rocker arms, timing chains, tensioners, and cylinder barrels

- Exhaust gas turbocharger

Lubricating System Types

- Four-stroke engines:

- Forced-feed lubrication

- Dry sump lubrication

- Two-stroke engines:

- Mixture lubrication

- Total-loss lubrication

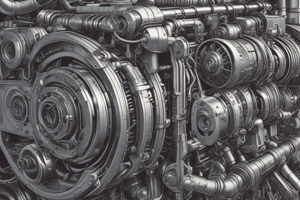

Forced-Feed Lubrication

- Commonly used in tractors, trucks, and automobiles.

- A pump draws oil from the oil pan, forcing it through pipes to lubrication points.

- Components include:

- Oil pressure pump, suction pump, oil pan, filter, cooler, dipstick

- Electric oil sensors display oil content and quality.

Dry Sump Lubrication

- Used in larger diesel engines and high-performance vehicles.

- Oil is collected in a separate reservoir rather than the oil pan.

- Pressurized oil delivery pump sends oil to lubrication points after filtration and cooling.

Advantages of Dry Sump Lubrication

- Flat oil pan reduces engine height and vehicle center of gravity.

- Ensures effective lubrication during high-angle, off-road, or high-speed situations.

- Better oil cooling due to separation from engine heat.

Engine Lubrication Components

- Major components include:

- Oil pan, oil pump, oil filter, oil pressure gauge, oil cooler

- Oil pressure switch, pressure limiting valve, and ventilation system.

Oil Pan Function

- Holds oil supply and contains anti-rolling baffle plates to prevent oil movement during dynamic conditions.

- Acts as a cooling surface for the oil.

Oil Pumps

- Maintain adequate oil pressure with a delivery flow of 250 to 350 liters per hour.

- Types of oil pumps:

- Gear pumps

- Crescent pumps

- Rotor pumps

Gear Pump

- Carries oil in tooth spaces, delivering through the pump wall.

- Prevents backflow through meshed teeth, creating varying pressures.

Crescent Pump

- An advanced gear pump where the inner gear sits on the crankshaft.

- Achieves higher delivery rates, especially at low speeds.

Rotor Pump

- Consists of an outer and inner rotor, generating high pressure and uniform flow.

Regulated Rotor Pump

- Maintains constant oil pressure through control mechanisms that adjust chamber sizes based on pressure changes.

Oil Pressure Gauge and Indicator Lamp

- Monitors oil pressure; the gauge provides direct readings while the lamp signals pressure sufficiency.

Pressure Limiting Valve

- Protects against excessive oil pressure (> 5 bar) to prevent damage to seals and hoses.

Oil Filter

- Prevents impurities from deteriorating lubricant properties.

- Types:

- Full-flow oil filter: ensures oil doesn’t reach lubrication points unfiltered.

- Partial-flow/bypass oil filter.

Crankcase Ventilation

- Handles blow-by gases in spark ignition and turbocharged diesel engines, returning contaminant-laden gases to intake via an oil separator.

Engine Oil

- Viscosity varies with temperature; higher viscosity results in elevated oil pressure when cold.

- Plays a crucial role in lubrication and engine performance.

Engine Oil Types

- Base oils (mineral): Derived from crude oil distillation; modified with additives for stability and protection.

- Synthetic oils: Man-made lubricants offering enhanced performance.

Engine Oil Specification

- SAE viscosity grades categorize oils by thickness; ranges include single-grade (e.g., SAE 10W) and multigrade (e.g., SAE 15W-50).

Oil Additives

- Enhancements added to base oils to meet diverse engine demands and improve performance.

Stresses of Lubricant Oils

- Common issues include oil aging, sludging, dilution, thickening, and consumption.

Maintenance, Problems, and Troubleshooting

- Regular checks and maintenance are crucial to prevent lubrication system failures.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.