Podcast

Questions and Answers

What type of cable is planned for connectivity between the E.I and sub-systems to prevent damage from surge and lightning?

What type of cable is planned for connectivity between the E.I and sub-systems to prevent damage from surge and lightning?

- Coaxial cable

- Copper wire

- Optical fiber cable (correct)

- Twisted pair cable

What is the primary purpose of the Factory Acceptance Test (FAT) for Electronic Interlocking?

What is the primary purpose of the Factory Acceptance Test (FAT) for Electronic Interlocking?

- Simulating operational scenarios to ensure software functionality (correct)

- Conducting real-time equipment functional testing

- Testing installed hardware at the site

- Verifying cross table with physical hardware

During the Site Acceptance Test (SAT), which of the following tests is NOT performed?

During the Site Acceptance Test (SAT), which of the following tests is NOT performed?

- Logic and interlocking testing

- Control Table testing

- Cross Table testing

- Software installation testing (correct)

Which of the following tests is specifically included during FAT for Electronic Interlocking?

Which of the following tests is specifically included during FAT for Electronic Interlocking?

What kind of testing is emphasized during the SAT for a new installation?

What kind of testing is emphasized during the SAT for a new installation?

In SAT for alteration works, which condition allows certain tests to be skipped?

In SAT for alteration works, which condition allows certain tests to be skipped?

Which type of testing is included in the SAT process following the interface with field gears?

Which type of testing is included in the SAT process following the interface with field gears?

What distinguishes the tests performed during FAT from those performed during SAT?

What distinguishes the tests performed during FAT from those performed during SAT?

What must happen whenever modifications are carried out to the Application logic?

What must happen whenever modifications are carried out to the Application logic?

Who is responsible for approving the version and checksum of the Application logic?

Who is responsible for approving the version and checksum of the Application logic?

What is required for maintaining the Checksum records?

What is required for maintaining the Checksum records?

What type of cabinets should the Electronic Interlocking system be installed in?

What type of cabinets should the Electronic Interlocking system be installed in?

What should be done to reduce EMI and EMC effects in the Electronic Interlocking system?

What should be done to reduce EMI and EMC effects in the Electronic Interlocking system?

What is a necessary condition for the Application logic used in the Electronic Interlocking system?

What is a necessary condition for the Application logic used in the Electronic Interlocking system?

Which of the following is not a guideline for installing the Electronic Interlocking system?

Which of the following is not a guideline for installing the Electronic Interlocking system?

Who should verify the safety and functionality of Application logic?

Who should verify the safety and functionality of Application logic?

What type of flooring is recommended for the Electronic Interlocking room?

What type of flooring is recommended for the Electronic Interlocking room?

Which type of ladders should be used for carrying wires in the Electronic Interlocking room?

Which type of ladders should be used for carrying wires in the Electronic Interlocking room?

How should entries to the Electronic Interlocking room be treated?

How should entries to the Electronic Interlocking room be treated?

What is required near electronic equipment to prevent electrostatic damage?

What is required near electronic equipment to prevent electrostatic damage?

What environmental control is essential in the room where Electronic Interlocking is installed?

What environmental control is essential in the room where Electronic Interlocking is installed?

What is the minimum distance that should be maintained between clean and dirty wiring?

What is the minimum distance that should be maintained between clean and dirty wiring?

How should clean and dirty wiring be routed when segregation is not feasible?

How should clean and dirty wiring be routed when segregation is not feasible?

What class of devices is required for surge protection for external interface ports?

What class of devices is required for surge protection for external interface ports?

What test is specifically mentioned for checking new additions to the system?

What test is specifically mentioned for checking new additions to the system?

What is the maximum allowable voltage loss for wires connecting equipment in Electronic Interlocking systems?

What is the maximum allowable voltage loss for wires connecting equipment in Electronic Interlocking systems?

Where should the Factory Acceptance Test (FAT) preferably be conducted?

Where should the Factory Acceptance Test (FAT) preferably be conducted?

Which of the following is a requirement for the power supply arrangements in E.I systems?

Which of the following is a requirement for the power supply arrangements in E.I systems?

Who should preferably conduct the FAT and SAT?

Who should preferably conduct the FAT and SAT?

What kind of external supply should power the fan in Electronic Interlocking?

What kind of external supply should power the fan in Electronic Interlocking?

What should be tested when existing I/O and communication ports are disturbed?

What should be tested when existing I/O and communication ports are disturbed?

What should the periodicity of tests be for existing installations of Electronic Interlocking?

What should the periodicity of tests be for existing installations of Electronic Interlocking?

Flashcards

Software Version Control

Software Version Control

Managing changes and versions of software for electronic interlocking systems.

Application Logic Version

Application Logic Version

Unique version number for each installation's station-specific software logic.

Checksum Approval

Checksum Approval

Validating the integrity of application logic through unique checksums.

Checksum Modifications

Checksum Modifications

Signup and view all the flashcards

Installation Guidelines

Installation Guidelines

Signup and view all the flashcards

Safety and Functionality Tests

Safety and Functionality Tests

Signup and view all the flashcards

Approved Application Logic

Approved Application Logic

Signup and view all the flashcards

Dust Proof Cabinets

Dust Proof Cabinets

Signup and view all the flashcards

Interlocking Room Flooring

Interlocking Room Flooring

Signup and view all the flashcards

Wire Routing

Wire Routing

Signup and view all the flashcards

Rodent and Insect Control

Rodent and Insect Control

Signup and view all the flashcards

Electrostatic Discharge Protection

Electrostatic Discharge Protection

Signup and view all the flashcards

Air Conditioning Requirements

Air Conditioning Requirements

Signup and view all the flashcards

Lightning Protection

Lightning Protection

Signup and view all the flashcards

Power Line Protection

Power Line Protection

Signup and view all the flashcards

Clean and Dirty Wiring Separation

Clean and Dirty Wiring Separation

Signup and view all the flashcards

Factory Acceptance Test (FAT)

Factory Acceptance Test (FAT)

Signup and view all the flashcards

Site Acceptance Test (SAT)

Site Acceptance Test (SAT)

Signup and view all the flashcards

Control Table Testing

Control Table Testing

Signup and view all the flashcards

Cross Table Testing (Square Sheet Testing)

Cross Table Testing (Square Sheet Testing)

Signup and view all the flashcards

Intercommunication Test

Intercommunication Test

Signup and view all the flashcards

Correspondence Test

Correspondence Test

Signup and view all the flashcards

Redundant OFC Cable

Redundant OFC Cable

Signup and view all the flashcards

Testing for Alteration Works

Testing for Alteration Works

Signup and view all the flashcards

FAT (Factory Acceptance Test)

FAT (Factory Acceptance Test)

Signup and view all the flashcards

SAT (Site Acceptance Test)

SAT (Site Acceptance Test)

Signup and view all the flashcards

Redundant Power Supply

Redundant Power Supply

Signup and view all the flashcards

Voltage Loss in Wiring

Voltage Loss in Wiring

Signup and view all the flashcards

Fan Power Isolation

Fan Power Isolation

Signup and view all the flashcards

Lightning & Surge Protection

Lightning & Surge Protection

Signup and view all the flashcards

Study Notes

Version Control of Electronic Interlocking Software and Hardware

- Approved versions of the generic system software and hardware are controlled by competent authorities.

- Application logic (station-specific) versions and checksums are unique per installation and approved by the circuit diagram approving authority.

- Checksums are recorded and controlled.

- Version numbers and checksums change with any application logic modifications.

- Proper checksum records are kept at station, divisional, and zonal headquarters.

Installation of Electronic Interlocking

- Installation follows approved guidelines and technical advisories.

- Application logic safety and functionality are verified through exhaustive tests performed by authorized personnel.

- Only approved application logic with checksums is used.

- Railways maintain and control the approved checksums.

- Interlocking systems are housed in approved dustproof cabinets with transparent doors.

- Interface relays are paralleled for increased reliability.

- Spare input/output cables are wired to Wago terminals for future adjustments.

- Input/output cables are twisted for minimized EMI and EMC.

- Electronic Interlocking should be placed close to the operator's room.

- Direct track crossings between the E.I room and the main system should be avoided.

- The E.I room floor and walls are tiled/similar material to prevent painting related dust.

Electronic Interlocking Room

- FRP or insulated ladders are used for wiring.

- Room entries are sealed to prevent entry of pests.

- Electrostatic floor pads and hand bands are used near the equipment to prevent electrostatic discharges.

- Air conditioning is required in the E.I room.

Building/Room Protection

- External lightning protection is at the top of buildings.

- If another metal structure provides protection, Class A protection isn't needed, but building guidelines are followed.

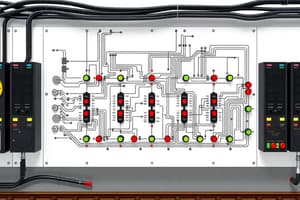

- Surge and lightning protection is provided to power lines in an Electronic Equipment Room.

- Separate power supply lines are used for the Electronic Equipment Room.

- Clean and dirty wires are kept separate, with a 150mm minimum distance.

- Clean and dirty wires crossing must be perpendicular.

- Surge protection is in place for all copper-based interfaces.

- Communications are via Optical Fiber Cable (OFC) for redundancy.

Testing of Electronic Interlocking

- Factory Acceptance Test (FAT): Uses computer simulation to verify interlocking application software.

- Testing does not include interface checks as hardware is not present and only reduced time application software interaction is checked.

- Site Acceptance Test (SAT): Site testing with hardware and a simulation panel, including interface verification (after connecting to field gears)

- Tests can differ for new installations vs site alterations.

- Different tests include checking logic, interlocking, interface equipment functionality, cross tables, control tables, and intercommunication between sub-racks/correspondence.

Power Supply

- Redundancy in power supply and controls is required following specifications.

- Wires should limit voltage loss to 0.5%.

- Separate power supplies are required for fans, isolated from the E.I system's power supply.

- Fuses are required.

Lightning and Surge Protection and Earthing

- Rules around lightning and surge protection and earthing are included in a dedicated section.

- Wiring, testing, and commissioning are aligned with section 19.8.

Maintenance

- Periodic tests for existing installations (relay/electronic interlocking):

- Physical inspection (annual/as needed)

- System integrity (every 5 years/when alterations happen)

- Insulation testing on cables

- Apparatus testing in aligned with specifications.

- Electrical signal circuits will be tested by signal staff for installations with up to 20 routes / more than 20 routes respectively.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Related Documents

Description

This quiz covers key aspects of version control and installation procedures for electronic interlocking software and hardware systems. It highlights the importance of maintaining approved versions, checksums, and installation guidelines to ensure safety and functionality. Test your knowledge on the regulations and practices that govern these systems in the railway sector.