Podcast

Questions and Answers

What is the primary purpose of the sheath in a cable?

What is the primary purpose of the sheath in a cable?

- To carry the electrical current.

- To protect the cable against mechanical damage. (correct)

- To reduce the cable's weight.

- To provide electrical insulation between conductors.

The new color code for electrical cables was implemented and became compulsory before March 2011.

The new color code for electrical cables was implemented and became compulsory before March 2011.

False (B)

What material is commonly used as insulation in fire-resistant cables designed to operate at temperatures up to 250°C?

What material is commonly used as insulation in fire-resistant cables designed to operate at temperatures up to 250°C?

Magnesium Oxide

Cables that are buried underground often use ______ cables to protect against mechanical damage.

Cables that are buried underground often use ______ cables to protect against mechanical damage.

Which of the following is a characteristic of multi-core cables compared to single-core cables?

Which of the following is a characteristic of multi-core cables compared to single-core cables?

Match the cable component with its typical function.

Match the cable component with its typical function.

In the cable specification 4C,120 mm2 Cu/XLPE/PVC /SWA/PVC + 70 mm2 Cu/PVC/CPC, what does 'XLPE' indicate?

In the cable specification 4C,120 mm2 Cu/XLPE/PVC /SWA/PVC + 70 mm2 Cu/PVC/CPC, what does 'XLPE' indicate?

Polyester (mylar) tape is typically used as armouring for cables.

Polyester (mylar) tape is typically used as armouring for cables.

What is the primary reason for using single-core cables beyond 120 mm² in size?

What is the primary reason for using single-core cables beyond 120 mm² in size?

Final circuits typically carry larger currents compared to submain cables.

Final circuits typically carry larger currents compared to submain cables.

Which of the following components is a key addition to fire-resistant (FR) cables compared to standard cables?

Which of the following components is a key addition to fire-resistant (FR) cables compared to standard cables?

Busducts are primarily used in low-current applications because of their large physical size compared to cables.

Busducts are primarily used in low-current applications because of their large physical size compared to cables.

According to the guidelines, if phase conductors are 50 mm², what should be the minimum size of the CPC?

According to the guidelines, if phase conductors are 50 mm², what should be the minimum size of the CPC?

What are three applications of FR cables?

What are three applications of FR cables?

Cables used in final circuits typically range from ______ mm².

Cables used in final circuits typically range from ______ mm².

The Cat CWZ fire resistance test ensures that a cable remains conductive at a temperature of 950°C for 3 hours, even under water-spray and ______ impact conditions.

The Cat CWZ fire resistance test ensures that a cable remains conductive at a temperature of 950°C for 3 hours, even under water-spray and ______ impact conditions.

Match the cable characteristic with its effect on current carrying capacity:

Match the cable characteristic with its effect on current carrying capacity:

Which factor does NOT directly influence the current carrying capacity of a cable?

Which factor does NOT directly influence the current carrying capacity of a cable?

Match the characteristics with either Cables or Busducts:

Match the characteristics with either Cables or Busducts:

Using a cable with an undersized cross-sectional area will always immediately result in a short circuit and fire.

Using a cable with an undersized cross-sectional area will always immediately result in a short circuit and fire.

What is a consequence of running cables in an enclosed environment with poor ventilation?

What is a consequence of running cables in an enclosed environment with poor ventilation?

What is the primary concern when using cable support systems in electrical installations?

What is the primary concern when using cable support systems in electrical installations?

According to the examples, a voltage drop of 4.35% in a cable is generally considered acceptable under normal operating conditions.

According to the examples, a voltage drop of 4.35% in a cable is generally considered acceptable under normal operating conditions.

What type of cable support is typically used for managing large cables in an electrical installation?

What type of cable support is typically used for managing large cables in an electrical installation?

According to CP5, all wirings installed within a wall must have adequate __________ protection.

According to CP5, all wirings installed within a wall must have adequate __________ protection.

What factors contribute most significantly to an increase in cable resistance?

What factors contribute most significantly to an increase in cable resistance?

Concealed conduit is suitable for surface mounting a switched-socket outlet.

Concealed conduit is suitable for surface mounting a switched-socket outlet.

What is the recommended cable size for lighting circuits according to the guide?

What is the recommended cable size for lighting circuits according to the guide?

Using an inadequately sized cable poses no risk as long as the circuit breaker is functioning correctly.

Using an inadequately sized cable poses no risk as long as the circuit breaker is functioning correctly.

In the calculation of voltage drop ($V_d$), what two factors are multiplied together?

In the calculation of voltage drop ($V_d$), what two factors are multiplied together?

Match the wiring component type with its typical installation method:

Match the wiring component type with its typical installation method:

What is the maximum allowable voltage drop from the origin of the electrical installation to the socket outlet or fixed equipment terminals?

What is the maximum allowable voltage drop from the origin of the electrical installation to the socket outlet or fixed equipment terminals?

Cable insulation will degrade slowly over time due to ______.

Cable insulation will degrade slowly over time due to ______.

A cable with an IFL of 35A is used in a system, but its current carrying capacity (CCC) is rated for 32A. What is the most likely consequence?

A cable with an IFL of 35A is used in a system, but its current carrying capacity (CCC) is rated for 32A. What is the most likely consequence?

Which of the following is NOT a suggested solution for addressing voltage drop issues in an electrical installation?

Which of the following is NOT a suggested solution for addressing voltage drop issues in an electrical installation?

A 3-phase system typically operates at 230V ± 10%.

A 3-phase system typically operates at 230V ± 10%.

Match the following components with their typical voltage tolerance:

Match the following components with their typical voltage tolerance:

What are the main disadvantages associated with using busducts?

What are the main disadvantages associated with using busducts?

Horizontal busducts in factories are typically installed at ground level for easy access.

Horizontal busducts in factories are typically installed at ground level for easy access.

List three factors that influence the current carrying capacity of a cable.

List three factors that influence the current carrying capacity of a cable.

Inadequate cable size can lead to a temperature increase, insulation __________, and potentially a fire.

Inadequate cable size can lead to a temperature increase, insulation __________, and potentially a fire.

Match the cable color identification with the corresponding system (old or new):

Match the cable color identification with the corresponding system (old or new):

What is the primary purpose of a fire barrier in fire retardant cables?

What is the primary purpose of a fire barrier in fire retardant cables?

A voltage drop of 5% is generally acceptable for most equipment.

A voltage drop of 5% is generally acceptable for most equipment.

What conditions are specified for Conductive Water Zone (CWZ) cables?

What conditions are specified for Conductive Water Zone (CWZ) cables?

Flashcards

Oversheath

Oversheath

A protective outer layer made of flame retardant PVC type ST2 or LSHF compound.

Submain cables

Submain cables

Cables designed to carry large currents, typically used in larger installations.

Final circuits

Final circuits

Cables that carry small currents, generally ranging from 1.5 to 4 mm².

CPC cable size

CPC cable size

Signup and view all the flashcards

Current carrying capacity

Current carrying capacity

Signup and view all the flashcards

Ambient temperature

Ambient temperature

Signup and view all the flashcards

Installation factor

Installation factor

Signup and view all the flashcards

Grouping factor

Grouping factor

Signup and view all the flashcards

Silicone Rubber

Silicone Rubber

Signup and view all the flashcards

Magnesium Oxide

Magnesium Oxide

Signup and view all the flashcards

Cable Sheath

Cable Sheath

Signup and view all the flashcards

Single Core Cable

Single Core Cable

Signup and view all the flashcards

Multi Core Cable

Multi Core Cable

Signup and view all the flashcards

Cable Specification X

Cable Specification X

Signup and view all the flashcards

Insulation Material

Insulation Material

Signup and view all the flashcards

Armoured Cable

Armoured Cable

Signup and view all the flashcards

Cable Sizing Standards

Cable Sizing Standards

Signup and view all the flashcards

Inadequately Sized Cable

Inadequately Sized Cable

Signup and view all the flashcards

Temperature Increase Effects

Temperature Increase Effects

Signup and view all the flashcards

Current Carrying Capacity (CCC)

Current Carrying Capacity (CCC)

Signup and view all the flashcards

Voltage Drop

Voltage Drop

Signup and view all the flashcards

Acceptable Voltage Regulation

Acceptable Voltage Regulation

Signup and view all the flashcards

Cable Resistance

Cable Resistance

Signup and view all the flashcards

Effects of Increased Ambient Temperature

Effects of Increased Ambient Temperature

Signup and view all the flashcards

Fire Retardant Cables

Fire Retardant Cables

Signup and view all the flashcards

Busducts

Busducts

Signup and view all the flashcards

Function of Busducts

Function of Busducts

Signup and view all the flashcards

CWZ Cable

CWZ Cable

Signup and view all the flashcards

Sprinkler Pump

Sprinkler Pump

Signup and view all the flashcards

Cable Tray

Cable Tray

Signup and view all the flashcards

Voltage Drop Formula

Voltage Drop Formula

Signup and view all the flashcards

Voltage Drop Tolerance

Voltage Drop Tolerance

Signup and view all the flashcards

Support Systems

Support Systems

Signup and view all the flashcards

Actual Cable Drop

Actual Cable Drop

Signup and view all the flashcards

Disadvantages of Busducts

Disadvantages of Busducts

Signup and view all the flashcards

Cable Ambient Temperature Effect

Cable Ambient Temperature Effect

Signup and view all the flashcards

Cable Ladder

Cable Ladder

Signup and view all the flashcards

Concealed Conduit

Concealed Conduit

Signup and view all the flashcards

Mechanical Protection

Mechanical Protection

Signup and view all the flashcards

CP5 Regulations

CP5 Regulations

Signup and view all the flashcards

Study Notes

Cables and Support Systems

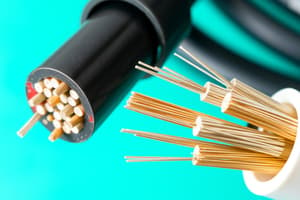

- Cables are insulated conductors.

- Cables consist of conductors, insulation, and mechanical protection.

- Components include main, sub-mains, and final sub-circuits.

- Cable support systems: e.g., cable ladders, cable trays, and cable conduits.

- Fire resistance cables: designed for use in fire-prone environments, often using materials like magnesium oxide.

- Busducts: combine conductors, insulation, mechanical protection, and support into a single unit.

Cable Components

- Sheath: Protects the cable from damage.

- Conductor: Usually copper or aluminum, size determined by current rating. Stranded conductors offer flexibility.

- Insulator: Covers the conductor, with higher insulator sizes handling higher voltages.

Cables & Cable Components

- Cables are insulated conductors.

- Three main cable components are Conductor, Insulation, and Mechanical protection.

Conductor

- Conductor size is measured in mm².

- Conductor material is either copper or aluminum.

- Aluminum is lighter and cheaper, but has higher resistivity than copper, leading to a larger size for the same current carrying capacity. Copper is heavier and more expensive, but has lower resistivity.

- Stranded conductors are twisted together for flexibility during installation.

- Total cross-sectional area of individual wires in a stranded conductor is used to determine size.

Conductor/Insulator

- Stranded conductors are comprised of many small wires, enabling flexibility during installation.

- Conductor size is the total cross-sectional area of all wires, excluding air space.

- Insulators are the external coverings of conductors; protecting live conductors from contact.

Other Insulations

- Synthetic rubber insulators handle high temperatures up to 85°C.

- Silicone rubber is used for special applications in temperatures ranging from -60°C to 150°C.

- Magnesium oxide insulation is a fire-resistant insulator.

- MICC cables are fire resistant, able to operate at up to 250°C.

Color Code

- Color coding for electrical wiring standardizes connections in single-phase and three-phase systems.

- Old and new schemes exist.

Single Core and Multi Core

- Single core cables have single conductors, suitable for high-current applications.

- Multi core cables have multiple conductors, suitable for smaller size applications.

Cable Specification

- Specific cables have 3-phase configurations.

- The conductors have a cross-sectional area.

- Insulation is cross-linked polyethylene.

- Sheath is polyvinyl chloride.

- Separate earth cables have a calculated size.

Single & Multi Core Cables

- Conductors are usually stranded copper.

- Insulation is usually cross-linked polyethylene or other polymers.

- Fillers, binders, bedding, armouring, and oversheaths are used as necessary for mechanical protection or specific application needs.

Cable Specification

- Multicore cables are common up to a 120 mm² cross-sectional area.

- Submain cables handle high current loads.

- Final circuits have lower current requirements.

- Circuit protective conductors need their size calculated according to the phase conductors, typically less.

Selection of Cable Size

- Cable size selection is based on current carrying capacity and voltage drop.

Current Carrying Capacity

- Cable size directly affects the current-carrying capacity.

- Higher ambient temperatures reduce current-carrying capacity.

- Enclosures reduce current-carrying capacity.

- Multiple cables together reduce current-carrying capacity.

Selection of Cable Size

- Selecting a cable size requires consideration of ambient temperature, installation factor, grouping factor, and design standards.

- Small cable sizes can lead to overheating, damage, short circuits, and possible fire.

- Large cable sizes are wasteful.

- Standards provide minimum acceptable cable sizes for specific applications (e.g., lighting and power).

Guide from CP5

- Provides detailed information for calculating voltage drop.

What happens if a cable is inadequately sized?

- Inadequate cable sizing can cause conductor overheat.

- This can lead to insulation breakdown, short circuits, or even fires.

- Cable insulation degrades over time due to overheating. This should be avoided.

Voltage Drop

- Equipment voltage range varies with whether it's single or three phase.

- Allowable voltage drop should be considered in calculations.

- Drop should be less than 4% in overall wiring diagrams.

Cable Support

- Cable support systems include cable ladders, cable trays, and cable conduits.

- Use appropriate supports for individual cable types. Different systems cater to various cable sizes.

Installation Details for Socket

- CP5 regulations mandate adequate mechanical protection for wiring within walls, including connections.

- This is essential for safe operation within a building structure.

Cable Support System Installation

- Supports include metal trays or ladders, brackets, and channels.

- These systems are used in a variety of areas including buildings.

Fire Retardant Cables

- Fire retardant cables are designed to continue operating during fires, which is critical.

- Some cables have added fire resistant layers or compounds to give extra protection during a fire.

MICC & Mica-taped FR Cables

- Fire-resistant cables are tested under various conditions to ensure continuous safety, even in extreme situations.

- Materials used for the cables impact the result of these tests.

Functions of Busducts

- Busducts combine multiple functions into one unit. (conductor, insulation, mechanical protection, support)

- Busducts are smaller than cables for larger current requirements, and have lower resistance for high currents than cables.

Busducts

- Busducts combine multiple functions into a single unit.

- Busducts, used at high currents, have low resistance. This helps reduce wiring concerns.

- Busduct usage is common in high rise buildings and factories.

Busducts in Factories

- Horizontal busducts run extensively at high levels in factories.

- Droppers are installed where power is needed.

Cable Tray

- Cable trays are support structures for cables.

- Practical for many wiring needs.

Summary 1

- Summarizes cable components, color coding, cable drawings, current carrying capacity, and sizing criteria.

Summary 2

- Provides a summary of circuit voltage drops, support systems for mounting, and fire-resistant cable types.

Summary 3

- Busduct components, advantages (size, low resistance, ease of installation), and disadvantages (high cost, custom installation) are highlighted.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.