Podcast

Questions and Answers

What is the purpose of an Onlay in dentistry?

What is the purpose of an Onlay in dentistry?

tooth restoration (occlusal surface plus cusp(s))

Which materials are commonly used for indirect restorations in dentistry?

Which materials are commonly used for indirect restorations in dentistry?

- Dental Ceramics

- Composites

- Metals

- All of the above (correct)

Porcelain is known for its high tensile strength.

Porcelain is known for its high tensile strength.

False (B)

Porcelain-Fused-to-Metal restorations are advantageous due to their strong ____.

Porcelain-Fused-to-Metal restorations are advantageous due to their strong ____.

Match the following dental materials with their common uses:

Match the following dental materials with their common uses:

What is the main difference between an inlay and an onlay?

What is the main difference between an inlay and an onlay?

Which of the following is NOT a characteristic of ceramics used in dentistry?

Which of the following is NOT a characteristic of ceramics used in dentistry?

Porcelain-fused-to-metal restorations are more expensive than all-ceramic restorations.

Porcelain-fused-to-metal restorations are more expensive than all-ceramic restorations.

Match the porcelain types with their respective fusing temperatures:

Match the porcelain types with their respective fusing temperatures:

What does an inlay in dentistry refer to?

What does an inlay in dentistry refer to?

How is an onlay different from an inlay?

How is an onlay different from an inlay?

Which materials are used for indirect restorations in dentistry? Select all that apply.

Which materials are used for indirect restorations in dentistry? Select all that apply.

Porcelain is classified as a type of metal.

Porcelain is classified as a type of metal.

Study Notes

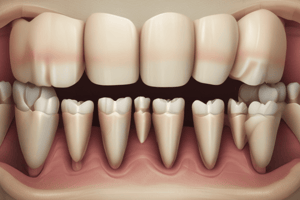

Indirect Restorations

- Inlays: indirect restorations that cover the occlusal surface, excluding cusps

- Onlays: indirect restorations that cover the occlusal surface, including cusps

- Crowns: usually cover the clinical crown of a natural tooth, can create “¾ crowns”

- Bridges: replace missing tooth/teeth, consisting of abutment and pontic (fake tooth)

Materials for Indirect Restorations

- Dental Ceramics (Porcelains):

- Uses: crowns, veneers, fused to metal for crowns and bridges, denture teeth, inlays, and onlays

- Composites

- Metals

Ceramics Characteristics

- High melting point

- Low thermal and electrical conductivity

- High compressive strength and stiffness

- Low tensile strength

- Brittle (low toughness – able to fracture)

- Excellent esthetics

- Great biocompatibility

Composition of Ceramics

- Metal oxide compounds

- Building block of ceramics: silica (silicon dioxide molecule, SiO2)

- Can be amorphous or crystalline arrangement

- Components mined from the earth

- Porcelains are white and translucent ceramics

Types of Porcelain

- High-fusing: fuses at 1300-1350°C, used for denture teeth, highest strength and stability

- Medium-fusing: fuses at 1100-1250°C, used for all-ceramic restoratives

- Low-fusing: fuses at 850-1050°C, used for PFM restorations

Properties of Porcelain

- Great hardness

- Excellent wear resistance

- Can rapidly abrade tooth enamel

- Not ductile – very stiff

- Able to fracture; brittle

- Often used to veneer metals (PFM), especially in stress-bearing areas (posterior)

- Shrinkage occurs upon firing

Preparation of Porcelain

- Mixing powdered quartz, feldspar, and clay

- Mixing with water

- Painting “dentin” or core layer onto die or metallic framework

- Removing excess water and packing particles

- Placing in oven to “sinter” (heated below fusion point)

- Painting “enamel” onto porcelain core

- Firing die and cooling

- Painting stains onto outer surface

- Final high-temperature firing for “glaze” finish

- Cooling slowly

Porcelain-Fused-to-Metal (PFM)

- Advantages: strong core, supports porcelain, easy “seating” – cementation

- Disadvantages: esthetics not perfect, not as translucent, metallic margin, ions may discolor porcelain

- Uses: anterior and posterior restorations

All-Ceramic Restorations

- Superior esthetics

- Made of reinforced porcelains

- Added glass, alumina, leucite, magnesia, or zirconia

- Change in composition for better resistance to cracking

- Video

CAD-CAM System

- Milled porcelain restorations

- Computer-aided design (CAD) and computer-assisted machining (CAM)

- “CEREC” system by Sirona

- Uses porcelain blocks, milled in the office

- One-appointment indirect restorations

- Expensive start-up cost

Other Systems

- “Procera” system

- “Cerpress” system

- “Sinfony”, Targis/Vectris”, “belleGlass” composite materials

- Allow for conservative prep designs

- Have great esthetics

- Use etch, bonding agent, and resin cement

Metals

- Uses: full metallic crowns, bridges, inlays, onlays, substructure for PFM’s, substructure/framework for partial dentures, temporary crowns

- Properties:

- High thermal and electrical conductivity

- High ductility, opacity, and luster

- High strength and melting points

- Crystalline arrangement of atoms

- Forming metal objects:

- Heating metal beyond melting range

- Casting: heating metal and pouring into a mold

- Lost-wax technique used to create mold space

- Alloying: mixing 2 or more metals to create stronger, harder, and less expensive materials

- Requirements: strong, hard, biologically compatible, high resistance to corrosion and tarnish, easy to cast, not cost-prohibitive

- Alloy composition: noble metals (gold, platinum, palladium), base metal alloys (containing nickel, chromium)

- Gold alloys: adding copper and silver to improve strength

- Porcelain-fused-to-metal alloys: palladium added to eliminate discoloration and add strength

Indirect Restorations

- Inlays: indirect restorations that cover the occlusal surface, excluding cusps

- Onlays: indirect restorations that cover the occlusal surface, including cusps

- Crowns: usually cover the clinical crown of a natural tooth, can create “¾ crowns”

- Bridges: replace missing tooth/teeth, consisting of abutment and pontic (fake tooth)

Materials for Indirect Restorations

- Dental Ceramics (Porcelains):

- Uses: crowns, veneers, fused to metal for crowns and bridges, denture teeth, inlays, and onlays

- Composites

- Metals

Ceramics Characteristics

- High melting point

- Low thermal and electrical conductivity

- High compressive strength and stiffness

- Low tensile strength

- Brittle (low toughness – able to fracture)

- Excellent esthetics

- Great biocompatibility

Composition of Ceramics

- Metal oxide compounds

- Building block of ceramics: silica (silicon dioxide molecule, SiO2)

- Can be amorphous or crystalline arrangement

- Components mined from the earth

- Porcelains are white and translucent ceramics

Types of Porcelain

- High-fusing: fuses at 1300-1350°C, used for denture teeth, highest strength and stability

- Medium-fusing: fuses at 1100-1250°C, used for all-ceramic restoratives

- Low-fusing: fuses at 850-1050°C, used for PFM restorations

Properties of Porcelain

- Great hardness

- Excellent wear resistance

- Can rapidly abrade tooth enamel

- Not ductile – very stiff

- Able to fracture; brittle

- Often used to veneer metals (PFM), especially in stress-bearing areas (posterior)

- Shrinkage occurs upon firing

Preparation of Porcelain

- Mixing powdered quartz, feldspar, and clay

- Mixing with water

- Painting “dentin” or core layer onto die or metallic framework

- Removing excess water and packing particles

- Placing in oven to “sinter” (heated below fusion point)

- Painting “enamel” onto porcelain core

- Firing die and cooling

- Painting stains onto outer surface

- Final high-temperature firing for “glaze” finish

- Cooling slowly

Porcelain-Fused-to-Metal (PFM)

- Advantages: strong core, supports porcelain, easy “seating” – cementation

- Disadvantages: esthetics not perfect, not as translucent, metallic margin, ions may discolor porcelain

- Uses: anterior and posterior restorations

All-Ceramic Restorations

- Superior esthetics

- Made of reinforced porcelains

- Added glass, alumina, leucite, magnesia, or zirconia

- Change in composition for better resistance to cracking

- Video

CAD-CAM System

- Milled porcelain restorations

- Computer-aided design (CAD) and computer-assisted machining (CAM)

- “CEREC” system by Sirona

- Uses porcelain blocks, milled in the office

- One-appointment indirect restorations

- Expensive start-up cost

Other Systems

- “Procera” system

- “Cerpress” system

- “Sinfony”, Targis/Vectris”, “belleGlass” composite materials

- Allow for conservative prep designs

- Have great esthetics

- Use etch, bonding agent, and resin cement

Metals

- Uses: full metallic crowns, bridges, inlays, onlays, substructure for PFM’s, substructure/framework for partial dentures, temporary crowns

- Properties:

- High thermal and electrical conductivity

- High ductility, opacity, and luster

- High strength and melting points

- Crystalline arrangement of atoms

- Forming metal objects:

- Heating metal beyond melting range

- Casting: heating metal and pouring into a mold

- Lost-wax technique used to create mold space

- Alloying: mixing 2 or more metals to create stronger, harder, and less expensive materials

- Requirements: strong, hard, biologically compatible, high resistance to corrosion and tarnish, easy to cast, not cost-prohibitive

- Alloy composition: noble metals (gold, platinum, palladium), base metal alloys (containing nickel, chromium)

- Gold alloys: adding copper and silver to improve strength

- Porcelain-fused-to-metal alloys: palladium added to eliminate discoloration and add strength

Indirect Restorations

- Inlays: indirect restorations that cover the occlusal surface, excluding cusps

- Onlays: indirect restorations that cover the occlusal surface, including cusps

- Crowns: usually cover the clinical crown of a natural tooth, can create “¾ crowns”

- Bridges: replace missing tooth/teeth, consisting of abutment and pontic (fake tooth)

Materials for Indirect Restorations

- Dental Ceramics (Porcelains):

- Uses: crowns, veneers, fused to metal for crowns and bridges, denture teeth, inlays, and onlays

- Composites

- Metals

Ceramics Characteristics

- High melting point

- Low thermal and electrical conductivity

- High compressive strength and stiffness

- Low tensile strength

- Brittle (low toughness – able to fracture)

- Excellent esthetics

- Great biocompatibility

Composition of Ceramics

- Metal oxide compounds

- Building block of ceramics: silica (silicon dioxide molecule, SiO2)

- Can be amorphous or crystalline arrangement

- Components mined from the earth

- Porcelains are white and translucent ceramics

Types of Porcelain

- High-fusing: fuses at 1300-1350°C, used for denture teeth, highest strength and stability

- Medium-fusing: fuses at 1100-1250°C, used for all-ceramic restoratives

- Low-fusing: fuses at 850-1050°C, used for PFM restorations

Properties of Porcelain

- Great hardness

- Excellent wear resistance

- Can rapidly abrade tooth enamel

- Not ductile – very stiff

- Able to fracture; brittle

- Often used to veneer metals (PFM), especially in stress-bearing areas (posterior)

- Shrinkage occurs upon firing

Preparation of Porcelain

- Mixing powdered quartz, feldspar, and clay

- Mixing with water

- Painting “dentin” or core layer onto die or metallic framework

- Removing excess water and packing particles

- Placing in oven to “sinter” (heated below fusion point)

- Painting “enamel” onto porcelain core

- Firing die and cooling

- Painting stains onto outer surface

- Final high-temperature firing for “glaze” finish

- Cooling slowly

Porcelain-Fused-to-Metal (PFM)

- Advantages: strong core, supports porcelain, easy “seating” – cementation

- Disadvantages: esthetics not perfect, not as translucent, metallic margin, ions may discolor porcelain

- Uses: anterior and posterior restorations

All-Ceramic Restorations

- Superior esthetics

- Made of reinforced porcelains

- Added glass, alumina, leucite, magnesia, or zirconia

- Change in composition for better resistance to cracking

- Video

CAD-CAM System

- Milled porcelain restorations

- Computer-aided design (CAD) and computer-assisted machining (CAM)

- “CEREC” system by Sirona

- Uses porcelain blocks, milled in the office

- One-appointment indirect restorations

- Expensive start-up cost

Other Systems

- “Procera” system

- “Cerpress” system

- “Sinfony”, Targis/Vectris”, “belleGlass” composite materials

- Allow for conservative prep designs

- Have great esthetics

- Use etch, bonding agent, and resin cement

Metals

- Uses: full metallic crowns, bridges, inlays, onlays, substructure for PFM’s, substructure/framework for partial dentures, temporary crowns

- Properties:

- High thermal and electrical conductivity

- High ductility, opacity, and luster

- High strength and melting points

- Crystalline arrangement of atoms

- Forming metal objects:

- Heating metal beyond melting range

- Casting: heating metal and pouring into a mold

- Lost-wax technique used to create mold space

- Alloying: mixing 2 or more metals to create stronger, harder, and less expensive materials

- Requirements: strong, hard, biologically compatible, high resistance to corrosion and tarnish, easy to cast, not cost-prohibitive

- Alloy composition: noble metals (gold, platinum, palladium), base metal alloys (containing nickel, chromium)

- Gold alloys: adding copper and silver to improve strength

- Porcelain-fused-to-metal alloys: palladium added to eliminate discoloration and add strength

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Description

This quiz covers the concepts of inlays, onlays, crowns, and bridges in dentistry, including their definitions and differences. It also reviews the concepts of abutment and pontic in bridge construction.