Podcast

Questions and Answers

What is responsible for converting the rotational motion to linear action in a DC generator?

What is responsible for converting the rotational motion to linear action in a DC generator?

- Commutator (correct)

- Armature

- Stator

- Brushes

What principle states that an EMF appears perpendicularly across each loop of wire in the coil when the armature spins inside the magnetic field?

What principle states that an EMF appears perpendicularly across each loop of wire in the coil when the armature spins inside the magnetic field?

- Faraday's Law (correct)

- Ohm's Law

- Boyle's Law

- Newton's Law

What happens when adjacent loops on the armature have opposing magnetic fields due to a change in rotation direction?

What happens when adjacent loops on the armature have opposing magnetic fields due to a change in rotation direction?

- They amplify each other

- They short-circuit (correct)

- They cancel each other out

- They create a resistance

Why does a spark occur between two armature loops during the operation of a DC generator?

Why does a spark occur between two armature loops during the operation of a DC generator?

What is the purpose of using commutators in DC generators?

What is the purpose of using commutators in DC generators?

What is the primary function of a DC generator?

What is the primary function of a DC generator?

Which part of a DC generator contains the windings?

Which part of a DC generator contains the windings?

How does a DC generator convert the AC generated in the winding into DC current?

How does a DC generator convert the AC generated in the winding into DC current?

What is the purpose of the commutator in a DC generator?

What is the purpose of the commutator in a DC generator?

What fundamental principle does a DC generator operate on?

What fundamental principle does a DC generator operate on?

Flashcards are hidden until you start studying

Study Notes

DC Generator Basics

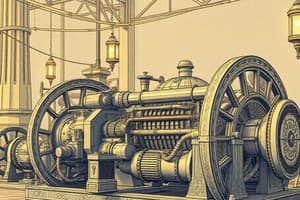

A Direct Current (DC) generator is an electrical machine designed to produce direct current from mechanical energy. It works on the principle of electromagnetic induction, where a magnet rotates within a stationary set of coils, creating an alternating voltage across the coils due to the changing magnetic field. This output can either be unidirectional or multidirectional depending on whether it uses commutators or diodes respectively. Here we'll delve into its functions, construction, working principles, applications, types, and maintenance requirements.

Functionality

The primary function of a DC generator is to convert mechanical power obtained through an external source like a steam turbine or diesel engine into electric power by utilizing the basic concepts of Faraday's Law of Electromagnetic Induction. A DC generator has three main parts; the armature which contains the windings, the stator housing the permanent magnets, and the commutator which facilitates the conversion of AC generated in the winding into DC current suitable for transmission over cables.

Construction

At its core, a DC generator consists of a cylindrical rotator called the armature enclosing multiple coils of wire wound around a hollow shaft. These copper coils form a series of loops known as conductors or slots attached to both ends of the casing to facilitate movement under mechanical force. On one end of these conductors sits the commutator - a split ring contactor with brushes pressed against them, converting the rotational motion to linear action. At the other end lies a stationary structure containing magnets arranged radially outwards along the circumference, forming an electromagnetic field whose polarity changes periodically while the armature turns.

Working Principles

When the armature spins inside the magnetic field created by the stator, an EMF (Electromotive Force) appears perpendicularly across each loop of wire in the coil according to Lenz's law. Since the magnetic fields of adjacent loops on the armature always have opposite polarities, they cancel each other out except when there's a change in direction of rotation. When this occurs, a momentary short circuit happens between two neighbors because their opposing magnetic fields will try to neutralize each other, causing a spark that heats up the carbon segment on the brush, eventually burning away some material until it breaks off and falls onto the rotater surface. As this cycle repeats itself continuously, internal resistance builds up heat in the conductor which must dissipate quickly lest it melt down! Now imagine if you could capture all those tiny individual DC pulses together into something bigger... That's how a full wave rectifier comes into play!.

This process generates an AC voltage across the ends of each turn, with a phase relationship determined by the relative positions of the conducting loop segments, resulting in an instantaneous difference in potential between any pair of armature terminals due to differences in position relative to the stator flux lines. However, since most systems require only unidirectional DC current delivery, devices called commutators are employed to reverse them periodically so that whatever changes occur do not affect operation during regular cyclic intervals.

Applications

DC generators find many practical applications such as battery charging, supplying DC motive power for mining equipment or traction locomotives, telegraphy & telephone networks, remote signaling systems like railway crossings, and even low cost standby systems for small isolated loads like residential water pumps. They also serve as reliable sources of emergency back-up power for critical infrastructure facilities including hospitals and data centers.

Types

There are two primary types of DC generators based upon the method used to control the flow of current from the device:

-

Brush type: Most commonly found everywhere requiring electricity generation from mechanical means, these employ physical contacts made by graphite blocks touching fixed metal surfaces running alongside conductors to establish the necessary connection.

-

Dry type: Similar in concept but without using liquid lubricants or solid particles, dry-type generators typically replace traditional hydraulic systems with air bearings supported by vacuum chambers instead of oil baths used in traditional designs.

Maintenance Requirements

Proper care and timely repair procedures help maintain optimal performance levels for your DC generator. Some key areas of focus for routine maintenance include checking brushes for wear, adjusting clearances between brushes and commutator rings, ensuring oil levels remain consistent (if applicable), cleaning dust from ventilation ports regularly, inspecting windings for damage caused by arcing, and ensuring proper alignment of moving components to prevent excessive friction. Also important is keeping track of loading patterns to predict when heavy maintenance might become mandatory before system failure strikes unexpectedly.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.