Podcast

Questions and Answers

What primary factor contributed to the crane hook striking the diver's helmet during the subsea operation?

What primary factor contributed to the crane hook striking the diver's helmet during the subsea operation?

- Inadequate communication between the diver and the diving supervisor regarding the rigging status.

- Insufficient length of the crane pennant/stinger, compounded by poor visibility. (correct)

- The diver's failure to maintain a safe distance from the pipe handling frame (PHF).

- The crane operator's lack of experience in subsea lifting operations.

In response to the incident, what measure was NOT implemented by the member to enhance safety?

In response to the incident, what measure was NOT implemented by the member to enhance safety?

- Updating the Job Hazard Analysis (JHA) to incorporate lessons learned regarding safe distances and visibility.

- Updating project procedures to specify minimum pennant lengths for different operations.

- Conducting pre-operation inspections of rigging and lifting equipment.

- Implementing a buddy system to ensure divers are always monitored by a colleague. (correct)

Which action taken during the incident demonstrated effective safety practices?

Which action taken during the incident demonstrated effective safety practices?

- The crane operator's continuation of lowering the hook despite the poor visibility.

- The use of standard communication protocols without adapting to the challenging subsea environment.

- The diver's immediate return to the dive bell after the helmet was struck. (correct)

- The diving supervisor's assumption that the hook had reached the seabed based on the 'no weight' reading.

What does the incident highlight about the role of technology in subsea operations?

What does the incident highlight about the role of technology in subsea operations?

How did the protective equipment contribute to a positive outcome in this incident?

How did the protective equipment contribute to a positive outcome in this incident?

Flashcards

Subsea Incident

Subsea Incident

During subsea spool tie-in, a crane hook struck a diver's helmet due to misjudgment of the hook's position.

Causes of the Incident

Causes of the Incident

Inadequate crane pennant length and poor visibility hindered accurate positioning, leading to the hook slipping and striking the diver.

Preventative Measures

Preventative Measures

Use sufficient crane pennant length, visibility aids (cameras, sonar), and clear communication to avoid equipment misplacement.

Positive actions to note

Positive actions to note

Signup and view all the flashcards

Challenge assumptions

Challenge assumptions

Signup and view all the flashcards

Study Notes

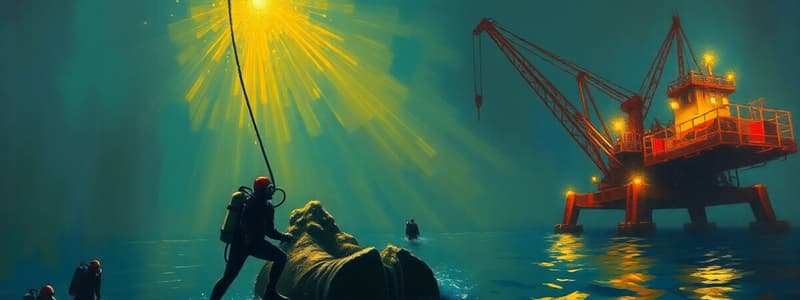

- During subsea spool tie-in operations, a crane hook unexpectedly struck a diver's helmet.

- Published 6 March 2025

- Generated 6 March 2025

- IMCA SF 04/25

What happened?

- Divers were working on the seabed in poor visibility during subsea spool tie-in operations.

- The Diving Supervisor instructed the crane operator to lower the crane hook to the seabed after landing the pipe handling frame (PHF).

- The instruction was to allow the diver to disconnect rigging from the crane.

- The crane operator reported 'no weight' on the crane wire.

- The Diving Supervisor then assumed the hook had reached the seabed.

- The supervisor instructed the diver to disconnect the PHF from the crane.

- The crane hook unexpectedly struck the diver's helmet while positioned beneath the PHF and moving up to disconnect the rigging.

- The diver was unharmed and returned to the dive bell, and the dive was aborted.

- The reclaim helmet was damaged beyond repair, but maintained integrity.

What went right?

- Diver 2 promptly assisted Diver 1, ensuring no injuries were sustained.

- The divers returned to bell safely.

- Both divers and the crane block had locating beacons fixed to them enabling accurate tracking.

- All procedures, lifting plans, and Job Hazard Analysis (JHA's) were followed throughout the operation.

- The protective equipment did its job, and the diver was uninjured because the impact was absorbed by the helmet.

What went wrong?

- The crane hook rested on the top beam of the PHF when lowered for PHF rigging disconnection.

- The resting resulted in a 'no weight' reading, leading the crane operator to assume the hook had reached the seabed.

- The hook slipped off the beam and struck the side of the diver's helmet as the diver approached the disconnection point.

What was the cause?

- Inadequate length of crane pennant/stinger did not provide sufficient distance between the divers and the crane hook.

- Poor visibility hindered the ability to accurately observe the position of the crane hook.

Lessons and actions

- Ensure adequate distance between divers and crane hook.

- The length of the crane pennant/stinger should be sufficient to maintain a safe distance between the divers and the crane hook during subsea operations.

- It reduces the risk of accidental contact with the hook, particularly in limited visibility conditions.

- Enhance visibility aids and monitoring by considering alternative methods in environments with poor visibility.

- Alternative methods involves additional locating beacons, underwater cameras, or sonar to better track the position of critical equipment like the crane hook.

- Improved monitoring can prevent misjudgements about the location of the crane hook.

- Reinforce communications and challenge assumptions.

- Assumptions regarding equipment position should be minimised.

- Clear communication and confirmation procedures between the dive supervisor, crane operator, and divers should be reinforced.

- Every party should be fully aware of the equipment's location at all times.

Member actions

- Updated project procedures to specify minimum pennant lengths for different operations.

- Conducted pre-operation inspections of all rigging and lifting equipment, including crane hooks and pennants, to ensure they meet safety standards and are appropriate for the operation.

- Updated the Job Hazard Analysis (JHA) to incorporate lessons learned from this incident, particularly regarding safe distances, visibility, and communication requirements for subsea lifting operations.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.