Podcast

Questions and Answers

What is the purpose of testing a cathodic protection system on an underground steel tank or gas piping?

What is the purpose of testing a cathodic protection system on an underground steel tank or gas piping?

- To assess the color of the tank surface

- To determine the level of corrosion protection provided by the system (correct)

- To check the tank's weight

- To measure the volume of gas in the tank

Which instrument can be used to measure the tank-to-soil potential in a cathodic protection system?

Which instrument can be used to measure the tank-to-soil potential in a cathodic protection system?

- pH meter

- Voltmeter and copper sulfate half cell reference electrode (correct)

- Thermometer

- Barometer

Why is it important to test cathodic protection systems periodically according to NFPA codes?

Why is it important to test cathodic protection systems periodically according to NFPA codes?

- To measure the gas volume in the tank

- To assess the color changes on the tank

- To ensure ongoing protection against corrosion (correct)

- To monitor the tank's weight

What should you do if your cathodic protection test results are unsatisfactory?

What should you do if your cathodic protection test results are unsatisfactory?

When should you consult with your supervisor regarding testing a cathodic protection system?

When should you consult with your supervisor regarding testing a cathodic protection system?

Why do inadequate cathodic protection readings lead to a shorter life for an underground steel tank or gas piping system?

Why do inadequate cathodic protection readings lead to a shorter life for an underground steel tank or gas piping system?

When should the initial test of the cathodic protection system be completed?

When should the initial test of the cathodic protection system be completed?

How often should follow-up testing be conducted for the cathodic protection system?

How often should follow-up testing be conducted for the cathodic protection system?

What should be done if a cathodic protection system fails a test?

What should be done if a cathodic protection system fails a test?

How long should documentation of test results be retained?

How long should documentation of test results be retained?

What is the purpose of a Portable Copper-Copper Sulfate Half Cell Reference Electrode?

What is the purpose of a Portable Copper-Copper Sulfate Half Cell Reference Electrode?

How should you prepare a Portable Copper-Copper Sulfate Half Cell Reference Electrode before use?

How should you prepare a Portable Copper-Copper Sulfate Half Cell Reference Electrode before use?

Why is it important to avoid over-tightening the copper rod assembly back onto the tube of the Portable Copper-Copper Sulfate Half Cell Reference Electrode?

Why is it important to avoid over-tightening the copper rod assembly back onto the tube of the Portable Copper-Copper Sulfate Half Cell Reference Electrode?

What is recommended to remove if found damaged during inspection of the Portable Copper-Copper Sulfate Half Cell Reference Electrode?

What is recommended to remove if found damaged during inspection of the Portable Copper-Copper Sulfate Half Cell Reference Electrode?

What is the purpose of letting the Portable Copper-Copper Sulfate Half Cell Reference Electrode sit for 24 hours after filling it with solution?

What is the purpose of letting the Portable Copper-Copper Sulfate Half Cell Reference Electrode sit for 24 hours after filling it with solution?

Why should you clean out the Portable Copper-Copper Sulfate Half Cell Reference Electrode every two or three months under normal conditions?

Why should you clean out the Portable Copper-Copper Sulfate Half Cell Reference Electrode every two or three months under normal conditions?

Study Notes

Initial Testing and Scheduling

- Initial testing must be completed after cathodic protection system installation, unless prohibited by extreme weather conditions.

- In cases of extreme weather, testing must be completed within 180 days of installation.

Follow-up Testing

- Conduct a follow-up test 12 to 18 months after the initial assessment.

- Periodic testing must be conducted at intervals of no more than 36 months.

Repair and Re-testing

- Systems that fail a test must be repaired promptly, unless climatic conditions prevent immediate action.

- In cases of delayed repair, repairs should be completed within 180 days.

- After repair, testing intervals begin again.

Documentation

- Retain documentation of the results from the two most recent tests to comply with the NFPA code.

- Follow company policy for documentation requirements.

Copper Half Cell Reference Electrodes

- Portable Copper-Copper Sulfate Half Cell Reference Electrodes consist of a plastic tube, copper rod, and copper sulfate solution.

- Inspect the copper rod to ensure it's smooth and shiny before use.

- Polish the copper rod with a non-metallic scouring pad or sandpaper to remove dirt or contaminants.

- Fill the tube with Copper Sulphate and distilled or deionized water, ensuring no crystals on the threads.

- Screw the plug assembly onto the tube end, being careful not to over-tighten.

- Let the electrode sit for 24 hours before using it.

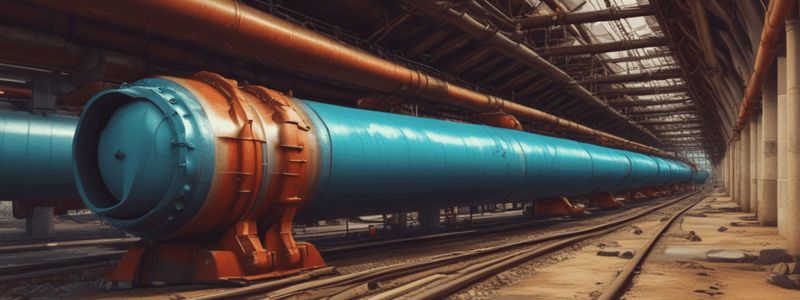

Testing Piping Systems

- Testing a piping system is performed similarly to testing a container, with one or more test stations set up along the piping.

- For propane containers, access the anode connections inside the tank dome for testing.

Cathodic Protection System Testing

- Testing determines the level of corrosion protection on the system.

- Insufficient cathodic protection can lead to corrosion and shorter system life.

- Testing involves checking the tank-to-soil potential, which is a measurement of the voltage or stored energy surrounding the tank and its piping.

- NFPA codes require testing at the time of installation and periodically to ensure system protection.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Description

Test your knowledge on the importance and methods of testing a cathodic protection system installed on underground steel propane tanks or metallic gas piping systems. Learn about the significance of determining corrosion protection levels and how to check tank-to-soil potential readings.