Podcast

Questions and Answers

What is one of the advantages of casting mentioned in the text?

What is one of the advantages of casting mentioned in the text?

- Quality issues with porosity

- Reduced material usage

- Limited size of castings

- Ability to produce complex shapes (correct)

Which industry uses casting to manufacture parts for aircraft?

Which industry uses casting to manufacture parts for aircraft?

- Medical

- Construction

- Aerospace (correct)

- Automotive

Which manufacturing process is stated as being more expensive than casting?

Which manufacturing process is stated as being more expensive than casting?

- Extrusion

- Welding

- Forging

- Machining (correct)

In what type of equipment are castings used in the construction industry?

In what type of equipment are castings used in the construction industry?

What is a major disadvantage of casting mentioned in the text?

What is a major disadvantage of casting mentioned in the text?

Which casting process involves creating a wax model covered in a refractory material?

Which casting process involves creating a wax model covered in a refractory material?

Which casting process uses sand as the mold material?

Which casting process uses sand as the mold material?

Which casting process involves using a metal die?

Which casting process involves using a metal die?

Which casting process is suitable for producing large quantities of castings?

Which casting process is suitable for producing large quantities of castings?

Which casting process is relatively inexpensive and suitable for producing a wide range of shapes and sizes?

Which casting process is relatively inexpensive and suitable for producing a wide range of shapes and sizes?

Flashcards are hidden until you start studying

Study Notes

Manufacturing Process: Casting Process

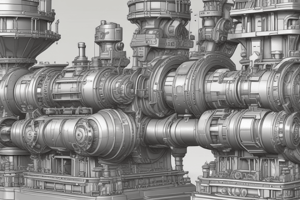

Casting is a manufacturing process in which a liquid material is poured into a mold, which contains a hollow cavity of the desired shape, and allowed to solidify. What is left is the desired shape in the solidified material. Casting is a very old technique, with some of the oldest known castings dating back more than 4,000 years.

Types of Casting Processes

There are several types of casting processes, each with its unique characteristics, advantages, and limitations. Some of the most common types include:

-

Permanent mold casting: In this process, a metal mold is used, which can be used multiple times. The mold is made from metal and is more durable than sand molds. Permanent mold casting is suitable for producing large quantities of castings.

-

Sand casting: This is the most common type of casting process. Sand is used as the mold material, which can be easily shaped and reused. Sand casting is suitable for producing a wide range of shapes and sizes, and it is relatively inexpensive.

-

Investment casting: Also known as lost wax casting, this process involves creating a wax model of the desired part, which is then covered in a refractory material, such as ceramic. The wax is melted out, leaving a shell of the refractory material. Molten metal is poured into the shell, which melts away, leaving the desired casting.

-

Die casting: This process involves using a metal die, which is much harder than the material being cast. Die casting is suitable for producing large quantities of very precise parts, and it is typically used for high-strength metals, such as aluminum and zinc.

Advantages and Disadvantages of Casting

Casting offers several advantages, including:

-

Complex shapes: Casting can produce very complex shapes that are difficult or impossible to manufacture using other processes.

-

High strength-to-weight ratio: Castings can have a high strength-to-weight ratio, making them ideal for applications where strength and weight are important factors.

-

Reduced material usage: Casting can reduce the amount of material used, as it is possible to create hollow structures within the casting, reducing the overall weight and cost.

However, casting also has some disadvantages:

-

Limited size: Castings are limited in size, as the mold must be able to be poured.

-

Quality issues: Castings can have issues with porosity, which can reduce their strength and durability.

-

Cost: Casting can be more expensive than other manufacturing processes, as it requires specialized equipment and skilled labor.

Applications of Casting

Casting is used in a wide range of industries and applications, including:

-

Aerospace: Casting is used to manufacture parts for aircraft, such as engine components and structural parts.

-

Automotive: Casting is used to manufacture parts for cars and trucks, such as engines, transmissions, and suspension components.

-

Construction: Casting is used to manufacture parts for construction equipment, such as cranes and excavators.

-

Medical: Casting is used to manufacture medical devices, such as prosthetic limbs and implants.

In conclusion, casting is a versatile and complex manufacturing process that has been used for thousands of years. It offers several advantages, including the ability to produce complex shapes and high strength-to-weight ratios, but it also has some disadvantages, such as limited size and quality issues. Despite these challenges, casting continues to be a popular and important manufacturing process in a wide range of industries.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.