Podcast

Questions and Answers

The primary purpose of nacelles is to reduce aerodynamic drag.

The primary purpose of nacelles is to reduce aerodynamic drag.

True (A)

What are cowling flaps used for on a nacelle?

What are cowling flaps used for on a nacelle?

regulate engine temperature

The region in stress-strain diagram from the origin to the elastic limit is called the __________ range.

The region in stress-strain diagram from the origin to the elastic limit is called the __________ range.

elastic

What is a bar element?

What is a bar element?

What are plates made to carry only in-plane axial loads called?

What are plates made to carry only in-plane axial loads called?

Compression is the resistance to stretching an object.

Compression is the resistance to stretching an object.

______ is the stress that resists a force that tends to pull something apart.

______ is the stress that resists a force that tends to pull something apart.

Match the following major structural stresses with their descriptions:

Match the following major structural stresses with their descriptions:

Flashcards are hidden until you start studying

Study Notes

Aircraft Structural Designs and Systems

- A structural system is a deformable solid body that carries loads and transmits them to other parts of the body.

- The constituents of a structural system are beams, plates, shells, or a combination of the three.

Bar Elements

- Bar elements are one-dimensional structural members that carry and transmit bending, shearing, torsional, and axial loads or a combination of the four.

- Bars that carry only axial loads are referred to as axial rods or two-force members.

- Structural systems constructed entirely out of axial rods are called trusses.

Plate Elements

- Plate elements are two-dimensional extensions of bar elements.

- Plates that carry only in-plane axial loads are called membranes.

- Those that carry only in-plane shearing loads are referred to as shear panels.

Shell Elements

- Shells are curved plate elements that occupy a space.

- Examples of shells include fuselages, building domes, and pressure vessels.

Bending Members

- A structural member that can carry bending moments is called a beam.

- A beam can also act as an axial member carrying longitudinal tension and compression.

Torsion Members

- Torque is an important form of load to aircraft structures.

- A member subjected to torsional moments would twist about a longitudinal axis through the shear center of the cross-section.

Major Structural Stresses

- There are five major stresses to which all aircraft are subjected: tension, compression, torsion, shear, and bending.

- Tension is the stress that resists a force that tends to pull something apart.

- Compression is the resistance to crushing produced by two forces pushing toward each other in the same straight line.

- Torsion is the stress that produces twisting.

- Shear is the stress that resists the force tending to cause one layer of a material to slide over an adjacent layer.

- Bending stress is a combination of compression and tension.

General Load Classification

- Loads can be classified into three categories: surface loads, body loads, and dynamic loads.

- Surface loads are produced by surface contact and include dynamic and/or static pressures.

- Body loads depend on body volume and include inertial, magnetic, and gravitational forces.

- Dynamic loads are time-dependent, whereas static loads are independent of time.

Wing Structure

- The main function of the wing is to pick up the air loads and transmit them to the fuselage.

- The wing cross-section takes the shape of an airfoil, which is designed based on aerodynamic considerations.

- The wing as a whole performs the combined function of a beam and a torsion member.

- The wing structure includes spars, ribs, and skin.

Wing Spar

- The spar is a heavy beam running spanwise to take transverse shear loads and spanwise bending.

- The spar is usually attached to the fuselage by wing fittings, plain beams, or a truss.

- The spar carries the loads caused by wing bending, with the caps providing a foundation for attaching the skin.

Wing Rib

- Wing ribs are planar structures capable of carrying in-plane loads.

- They are placed chordwise along the wing span.

- Ribs reduce the effective buckling length of the stringers and thus increase their compressive load capability.

Wing Skin

- The skin on a wing is designed to carry part of the flight and ground loads in combination with the spars and ribs.

- The skin is often used as a stressed-skin design, where fuel is carried inside the wings.

Wing Construction

- There are three fundamental designs of wing construction: monospar, multispar, and box-beam.

- The monospar wing incorporates only one main spanwise or longitudinal member in its construction.

- The multispar wing incorporates more than one main longitudinal member in its construction.

- The box-beam type of wing construction uses two main longitudinal members with connecting bulkheads.

Wing Attachment

- Wings are often of full cantilever design, meaning they are built so that no external bracing is needed.

- The semi-cantilever usually has one or perhaps two supporting wires or struts attached to each wing and the fuselage.

Fuselage Structure

- The fuselage is the main structure or body of the fixed-wing aircraft.

- There are two general types of fuselage construction: truss and monocoque.

- The truss-framed fuselage is generally covered with fabric, and is usually constructed of steel tubing welded together.

- The monocoque fuselage relies largely on the strength of the skin or covering to carry the primary loads.

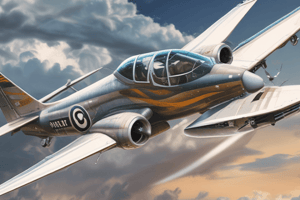

Nacelles

- Nacelles are streamlined enclosures used primarily to house the engine and its components.

- The nacelle contains the engine and accessories, engine mounts, structural members, a firewall, and skin and cowling on the exterior.

Empennage

- The empennage is the tail section of the aircraft.

- The structure of the stabilizers is very similar to that used in wing construction.

- The empennage consists of a tail cone, fixed aerodynamic surfaces or stabilizers, and movable aerodynamic surfaces.

Landing Gear

- The purpose of the landing gear is to provide a suspension system during taxi, take-off, and landing.

- The landing gear is designed to absorb and dissipate the force of a landing impact.

- The main structural components of a landing gear system are the shock absorber, axle, torque links, side braces, retraction actuators, wheels, and tires.

General Load Conditions

- The limit loads are the maximum anticipated loads in the entire service lifespan of the vehicle.

- The ultimate loads are the limit loads multiplied by a factor of safety.

- The limit loads and ultimate loads are often prescribed by specifying certain load factors.### Stress-Strain Diagram

- The stress-strain diagram is a graph that shows the relationship between stress (σ) and strain (ε) of a material.

- The diagram is obtained by plotting the stress and strain values measured during a tension-compression test.

Proportional Limit and Hooke's Law

- The proportional limit is the point on the stress-strain curve where the relationship between stress and strain is no longer linear.

- Within the proportional limit, the stress is directly proportional to the strain, which is known as Hooke's Law.

Elastic Limit and Elastic Range

- The elastic limit is the maximum stress that a material can withstand without undergoing permanent deformation.

- The elastic range is the region of the stress-strain diagram between the origin and the elastic limit, where the material returns to its original shape when the load is removed.

Plastic Range and Yielding

- The plastic range is the region of the stress-strain diagram to the right of the elastic limit, where the material undergoes permanent deformation.

- Yielding occurs when the material reaches its yield point, where a slight increase in stress causes a significant increase in strain.

- The yield stress is the stress at which yielding occurs.

Strain Hardening and Ultimate Stress

- Strain hardening is the process by which the material becomes stronger and more resistant to deformation as it is strained.

- The ultimate stress is the maximum stress that a material can withstand before failure.

Necking and Fracture

- Necking occurs when the material begins to constrict or form a neck in a localized region, leading to a decrease in cross-sectional area.

- The stress-strain diagram curves downward as the material approaches fracture.

True Stress and Strain

- True stress and strain are calculated using the actual cross-sectional area and length of the specimen at the instant the load is measured.

- The true stress-strain diagram shows the actual stress and strain values, which are different from the conventional stress-strain diagram.

Allowable Stress and Factor of Safety

- The allowable stress is the maximum safe stress that a material can carry.

- The allowable stress is typically taken as the yield point or ultimate strength divided by a factor of safety.

- The factor of safety is the ratio of the ultimate or yield strength to the allowable stress.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.