Podcast

Questions and Answers

What is the primary function of a Central Maintenance System (CMS)?

What is the primary function of a Central Maintenance System (CMS)?

- To provide in-flight entertainment to passengers.

- To centralize data related to aircraft fault events. (correct)

- To manage the aircraft's fuel consumption.

- To control the aircraft's navigation systems.

Which of the following is a typical input to a Central Maintenance Computer (CMC)?

Which of the following is a typical input to a Central Maintenance Computer (CMC)?

- Weather radar information.

- Passenger seat occupancy data.

- Aircraft system fault monitoring data. (correct)

- Galley equipment status.

In a dual CMC installation, what happens when the active CMC fails?

In a dual CMC installation, what happens when the active CMC fails?

- The flight crew must manually switch to a backup navigation system.

- All non-essential systems are shut down to conserve power.

- The standby CMC is automatically or manually selected. (correct)

- The aircraft is immediately grounded.

Which fault classification requires immediate action from the flight crew?

Which fault classification requires immediate action from the flight crew?

What is the purpose of Built-in Test Equipment (BITE)?

What is the purpose of Built-in Test Equipment (BITE)?

What is the difference between Automatic and Interruptive BITE?

What is the difference between Automatic and Interruptive BITE?

What is the function of the Multifunction Control Display Unit (MCDU) in relation to the CMC?

What is the function of the Multifunction Control Display Unit (MCDU) in relation to the CMC?

What type of information is typically found on the CMC's Message (MSG) pages?

What type of information is typically found on the CMC's Message (MSG) pages?

What is the purpose of 'Confidence Tests' within the CMC menu?

What is the purpose of 'Confidence Tests' within the CMC menu?

What is the role of the Aircraft Communications Addressing and Reporting System (ACARS) in relation to the CMS?

What is the role of the Aircraft Communications Addressing and Reporting System (ACARS) in relation to the CMS?

What are the typical ways to bring data onto an aircraft for data loading?

What are the typical ways to bring data onto an aircraft for data loading?

What is the primary difference between 'uploading' and 'downloading' in the context of aircraft data loading?

What is the primary difference between 'uploading' and 'downloading' in the context of aircraft data loading?

What is the purpose of a Software Repository or File Server on modern aircraft?

What is the purpose of a Software Repository or File Server on modern aircraft?

In the context of data loading, what is the difference between 'Staging' and 'Loading'?

In the context of data loading, what is the difference between 'Staging' and 'Loading'?

What are the four sub-functions carried out by the Central Maintenance Computer (CMC) in a typical data loading system?

What are the four sub-functions carried out by the Central Maintenance Computer (CMC) in a typical data loading system?

What is the primary function of the Electronic Library System (ELS)?

What is the primary function of the Electronic Library System (ELS)?

Which of the following is a typical component of a basic Electronic Library System (ELS) architecture?

Which of the following is a typical component of a basic Electronic Library System (ELS) architecture?

What is the purpose of an Electronic Flight Bag (EFB)?

What is the purpose of an Electronic Flight Bag (EFB)?

What type of information can be printed by the flight compartment printing system?

What type of information can be printed by the flight compartment printing system?

What does the amber FAULT LED on the flight deck printer indicate?

What does the amber FAULT LED on the flight deck printer indicate?

What is damage tolerance in the context of aircraft structure?

What is damage tolerance in the context of aircraft structure?

What is the purpose of Structural Health Monitoring (SHM)?

What is the purpose of Structural Health Monitoring (SHM)?

Why is it important to monitor fatigue imposed on an aircraft structure?

Why is it important to monitor fatigue imposed on an aircraft structure?

How do fatigue meters typically record stress levels on aircraft?

How do fatigue meters typically record stress levels on aircraft?

What do strain gauges measure on aircraft structures?

What do strain gauges measure on aircraft structures?

In a Wheatstone bridge circuit used with a strain gauge, what is the purpose of the resistor placed in an area not under stress?

In a Wheatstone bridge circuit used with a strain gauge, what is the purpose of the resistor placed in an area not under stress?

How do intelligent skins monitor the strain on composite materials?

How do intelligent skins monitor the strain on composite materials?

What is indicated by a 'Hard Failure' fault code type?

What is indicated by a 'Hard Failure' fault code type?

What is the nature of a 'Soft Failure' fault code type?

What is the nature of a 'Soft Failure' fault code type?

What is the significance of 'Maintenance Memos' as a failure fault code type?

What is the significance of 'Maintenance Memos' as a failure fault code type?

What triggers 'Failure Warnings' in the context of fault code types?

What triggers 'Failure Warnings' in the context of fault code types?

What is the function of the 'Existing Faults' page, accessed via the CMC menu?

What is the function of the 'Existing Faults' page, accessed via the CMC menu?

What information does the 'Fault History' function provide?

What information does the 'Fault History' function provide?

What are the advantages of Damage Tolerance Monitoring and SHM?

What are the advantages of Damage Tolerance Monitoring and SHM?

What is the purpose of performing “Data Load” selection on a MAT (Maintenance Access Terminal)?

What is the purpose of performing “Data Load” selection on a MAT (Maintenance Access Terminal)?

What type of EFB would you expect to find ODL (Onboard Data Load) functionality?

What type of EFB would you expect to find ODL (Onboard Data Load) functionality?

What is the likely effect of damage to the light transmitting fibres in an intelligent skin?

What is the likely effect of damage to the light transmitting fibres in an intelligent skin?

What is the significance of the 'crosstalk' function in a dual CMC installation?

What is the significance of the 'crosstalk' function in a dual CMC installation?

In the context of aircraft maintenance, what differentiates a 'soft failure' from a 'hard failure'?

In the context of aircraft maintenance, what differentiates a 'soft failure' from a 'hard failure'?

How does a system level BITE differ from a component level BITE?

How does a system level BITE differ from a component level BITE?

What is the primary purpose of accessing the 'PRESENT LEG FAULTS' function of the CMC?

What is the primary purpose of accessing the 'PRESENT LEG FAULTS' function of the CMC?

What role does the Aircraft Communications Addressing and Reporting System (ACARS) play in aircraft maintenance?

What role does the Aircraft Communications Addressing and Reporting System (ACARS) play in aircraft maintenance?

What is the key difference between 'staging' and 'loading' in the context of aircraft data loading?

What is the key difference between 'staging' and 'loading' in the context of aircraft data loading?

In a typical data loading system, which of the following is a sub-function carried out by the Central Maintenance Computer (CMC)?

In a typical data loading system, which of the following is a sub-function carried out by the Central Maintenance Computer (CMC)?

What is the primary benefit of integrating On-board Maintenance Systems (OMS) with the Electronic Library System (ELS)?

What is the primary benefit of integrating On-board Maintenance Systems (OMS) with the Electronic Library System (ELS)?

How does structural health monitoring (SHM) contribute to reducing maintenance costs for aircraft?

How does structural health monitoring (SHM) contribute to reducing maintenance costs for aircraft?

What is the fundamental principle behind the damage tolerance approach in aircraft structural design?

What is the fundamental principle behind the damage tolerance approach in aircraft structural design?

How do fatigue meters assist in structural health monitoring?

How do fatigue meters assist in structural health monitoring?

In a Wheatstone bridge circuit used with a strain gauge, what is the function of the variable resistor?

In a Wheatstone bridge circuit used with a strain gauge, what is the function of the variable resistor?

What aspect of light is monitored in an intelligent skin to assess strain on composite materials?

What aspect of light is monitored in an intelligent skin to assess strain on composite materials?

How does older generation aircraft typically differ from modern aircraft in terms of system testing?

How does older generation aircraft typically differ from modern aircraft in terms of system testing?

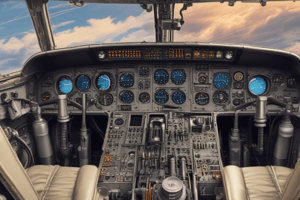

Which of the following best describes the typical location of Central Maintenance Computers (CMCs) in an aircraft?

Which of the following best describes the typical location of Central Maintenance Computers (CMCs) in an aircraft?

What is the significance of the 'weight on wheels' switch input to the CMC?

What is the significance of the 'weight on wheels' switch input to the CMC?

What is a typical storage capacity of aircraft for faults?

What is a typical storage capacity of aircraft for faults?

How is Level A fault classification typically represented to the flight crew?

How is Level A fault classification typically represented to the flight crew?

What is the function of units that are monitored by the CMC that contain circuits known as Built‑in Test Equipment (BITE)?

What is the function of units that are monitored by the CMC that contain circuits known as Built‑in Test Equipment (BITE)?

What is a characteristic of Interruptive or Manual BITE?

What is a characteristic of Interruptive or Manual BITE?

Which of the following is a typical indication that might be seen for Component Level BITE?

Which of the following is a typical indication that might be seen for Component Level BITE?

Which of the following conditions is essential for carrying out multi-system level BITE tests?

Which of the following conditions is essential for carrying out multi-system level BITE tests?

How is the CMC typically accessed on modern commercial aircraft?

How is the CMC typically accessed on modern commercial aircraft?

What information does the header of the CMC menu on the CDU indicate?

What information does the header of the CMC menu on the CDU indicate?

Which of the following pieces of data is typically found on CMC message pages?

Which of the following pieces of data is typically found on CMC message pages?

In the context of CMC fault messages, what does FDE stand for?

In the context of CMC fault messages, what does FDE stand for?

How is the start of a flight leg defined by the CMC if the engines are not shut down from the previous flight?

How is the start of a flight leg defined by the CMC if the engines are not shut down from the previous flight?

What is the main purpose of the 'Confidence Tests' function within the CMC?

What is the main purpose of the 'Confidence Tests' function within the CMC?

When would the MAINTENANCE ENABLE/DISABLE selection be used?

When would the MAINTENANCE ENABLE/DISABLE selection be used?

What is the purpose of performing “SYSTEM CONFIGURATION selection” on a MAT (Maintenance Access Terminal)?

What is the purpose of performing “SYSTEM CONFIGURATION selection” on a MAT (Maintenance Access Terminal)?

On the Flight Deck Printer, what does the green MSG LED indicate?

On the Flight Deck Printer, what does the green MSG LED indicate?

In structure monitoring, what does SHM stand for?

In structure monitoring, what does SHM stand for?

What is the primary functionality provided by an Electronic Flight Bag (EFB)?

What is the primary functionality provided by an Electronic Flight Bag (EFB)?

What is meant by the term 'damage tolerance' in reference to aircraft structure?

What is meant by the term 'damage tolerance' in reference to aircraft structure?

Excessive loads on an aircraft will trigger a warning in the onboard maintenance system, how is this accomplished?

Excessive loads on an aircraft will trigger a warning in the onboard maintenance system, how is this accomplished?

In a balanced Wheatstone bridge using strain gauges, what physical property changes in the strain gauge wire when tensile force is applied?

In a balanced Wheatstone bridge using strain gauges, what physical property changes in the strain gauge wire when tensile force is applied?

Which best describes the role of the Central Maintenance Computer (CMC) in modern aircraft?

Which best describes the role of the Central Maintenance Computer (CMC) in modern aircraft?

How does a dual CMC installation enhance system reliability?

How does a dual CMC installation enhance system reliability?

What is the primary differentiation between 'warnings' and 'cautions' in aircraft fault classification?

What is the primary differentiation between 'warnings' and 'cautions' in aircraft fault classification?

In the context of failure fault code types, what distinguishes a 'hard failure' from a 'soft failure'?

In the context of failure fault code types, what distinguishes a 'hard failure' from a 'soft failure'?

What is the role of 'Maintenance Memos' in the hierarchy of aircraft fault reporting?

What is the role of 'Maintenance Memos' in the hierarchy of aircraft fault reporting?

How does Automatic or Continuous BITE testing differ from Interruptive or Manual BITE testing?

How does Automatic or Continuous BITE testing differ from Interruptive or Manual BITE testing?

What is the significance of Multi-system Level BITE in aircraft maintenance?

What is the significance of Multi-system Level BITE in aircraft maintenance?

What is the role of the Multifunction Control Display Unit (MCDU) in accessing the Central Maintenance Computer (CMC)?

What is the role of the Multifunction Control Display Unit (MCDU) in accessing the Central Maintenance Computer (CMC)?

What is the primary function of the 'Present Leg Faults' page within the CMC menu?

What is the primary function of the 'Present Leg Faults' page within the CMC menu?

How does the Aircraft Communications Addressing and Reporting System (ACARS) contribute to aircraft maintenance operations?

How does the Aircraft Communications Addressing and Reporting System (ACARS) contribute to aircraft maintenance operations?

What is the core difference between 'staging' and 'loading' in the context of aircraft data loading procedures?

What is the core difference between 'staging' and 'loading' in the context of aircraft data loading procedures?

Which of the following is performed by the Central Maintenance Computer (CMC) as a sub-function within a typical data loading system?

Which of the following is performed by the Central Maintenance Computer (CMC) as a sub-function within a typical data loading system?

What is the role of the Software Maintenance Tool (SMT) in the new technology uploading and downloading process?

What is the role of the Software Maintenance Tool (SMT) in the new technology uploading and downloading process?

How does the integration of Onboard Maintenance Systems (OMS) with the Electronic Library System (ELS) benefit maintenance personnel?

How does the integration of Onboard Maintenance Systems (OMS) with the Electronic Library System (ELS) benefit maintenance personnel?

What defines the 'damage tolerance' approach in aircraft structural design and maintenance?

What defines the 'damage tolerance' approach in aircraft structural design and maintenance?

How does Structural Health Monitoring (SHM) enhance the inspection process for aircraft structures?

How does Structural Health Monitoring (SHM) enhance the inspection process for aircraft structures?

Why is it crucial to monitor fatigue imposed on an aircraft structure?

Why is it crucial to monitor fatigue imposed on an aircraft structure?

How do strain gauges typically function in monitoring stress on aircraft structures?

How do strain gauges typically function in monitoring stress on aircraft structures?

In a Wheatstone bridge circuit used with a strain gauge for structure monitoring, what is the role of the resistor placed in an area not under stress?

In a Wheatstone bridge circuit used with a strain gauge for structure monitoring, what is the role of the resistor placed in an area not under stress?

Flashcards

On-Board Maintenance System (OBMS)

On-Board Maintenance System (OBMS)

Electronic/computer-based systems used to monitor and record the performance and status of aircraft systems.

Central Maintenance System (CMS) function

Central Maintenance System (CMS) function

To monitor fault status, initiate tests, generate fault reports, upload/download data and isolate faults.

Central Maintenance Computer (CMC)

Central Maintenance Computer (CMC)

Main processing unit of the CMS that acquires, processes, and outputs data from aircraft systems.

Hard Failure

Hard Failure

Signup and view all the flashcards

Soft Failure

Soft Failure

Signup and view all the flashcards

Failure Warnings

Failure Warnings

Signup and view all the flashcards

Maintenance Messages

Maintenance Messages

Signup and view all the flashcards

Maintenance Memos

Maintenance Memos

Signup and view all the flashcards

Built-in Test Equipment (BITE)

Built-in Test Equipment (BITE)

Signup and view all the flashcards

Interruptive or Manual BITE

Interruptive or Manual BITE

Signup and view all the flashcards

Automatic or Continuous BITE

Automatic or Continuous BITE

Signup and view all the flashcards

Power Up BITE

Power Up BITE

Signup and view all the flashcards

Component Level BITE

Component Level BITE

Signup and view all the flashcards

System Level BITE

System Level BITE

Signup and view all the flashcards

Multi-system Level BITE

Multi-system Level BITE

Signup and view all the flashcards

Multifunction Control Display Unit (MCDU)

Multifunction Control Display Unit (MCDU)

Signup and view all the flashcards

Present Leg Faults

Present Leg Faults

Signup and view all the flashcards

Confidence Tests

Confidence Tests

Signup and view all the flashcards

Existing Faults

Existing Faults

Signup and view all the flashcards

Fault History

Fault History

Signup and view all the flashcards

Aircraft Communications Addressing and Reporting System (ACARS)

Aircraft Communications Addressing and Reporting System (ACARS)

Signup and view all the flashcards

Data Loading System

Data Loading System

Signup and view all the flashcards

Uploading

Uploading

Signup and view all the flashcards

Downloading

Downloading

Signup and view all the flashcards

Software Repository or File Server

Software Repository or File Server

Signup and view all the flashcards

Staging and Uploading

Staging and Uploading

Signup and view all the flashcards

Data Loading or Software Download

Data Loading or Software Download

Signup and view all the flashcards

Software Maintenance Tool (SMT)

Software Maintenance Tool (SMT)

Signup and view all the flashcards

Electronic Library System (ELS)

Electronic Library System (ELS)

Signup and view all the flashcards

Electronic Flight Bag (EFB)

Electronic Flight Bag (EFB)

Signup and view all the flashcards

Printer

Printer

Signup and view all the flashcards

Damage Tolerance

Damage Tolerance

Signup and view all the flashcards

Structure Health Monitoring (SHM)

Structure Health Monitoring (SHM)

Signup and view all the flashcards

Fatigue

Fatigue

Signup and view all the flashcards

Fatigue Meters

Fatigue Meters

Signup and view all the flashcards

Strain Gauges

Strain Gauges

Signup and view all the flashcards

Intelligent Skins

Intelligent Skins

Signup and view all the flashcards

Study Notes

Introduction to On-board Maintenance Systems

- Traditional aircraft troubleshooting involved individual switches and specific test methods for each system.

- Modern aircraft use On-Board Maintenance Systems (OBMS) to monitor and record system performance.

- OBMS monitors aircraft systems, records fault data, and provides information to the flight crew and engineer.

- Collected data is available in flight and on the ground for testing and troubleshooting.

- Some OBMS can relay fault information to the ground while in flight.

- OBMS can store maintenance manuals, troubleshooting guides and flight manuals for easy access.

Central Maintenance Systems (CMS)

- CMS monitors fault status, initiates system tests, generates fault reports, uploads/downloads data, and isolates faults.

- A CMS consists of:

- One or two Central Maintenance Computers (CMC).

- Two or three Multi‑purpose Control and Display Units (MCDU).

- The CMS centralizes data related to aircraft fault events.

- Maintenance systems differ in philosophy, design, and system structure across aircraft types.

Central Maintenance Computer (CMC)

- The Central Maintenance Computer (CMC) is the main processing unit of the CMS.

- CMC acquires, processes, and outputs data to and from aircraft systems.

- Inputs can be digital (ARINC 429) or analogue.

- Typical inputs:

- Aircraft system fault monitoring

- Operating modes and configuration status

- Flight modes

- Commands from flight crew and engineers

- An example is the input from the landing gear's weight on wheels switch to record the flight phase.

- Boeing aircraft store faults for 99 flights or 500 faults.

- Airbus aircraft store faults for a maximum of 63 flights.

- Discrete signals are converted via A/D converters allowing the CPU to process information.

- D/A Converters convert digital to analogue to activate a system test sequence, to activate an indicator such as a warning LED or produce sound at a speaker.

- Dual CMC installations are common on commercial aircraft:

- One CMC is active, and the other is on standby.

- A fault monitoring circuit within each CMC controls a "data switch".

- 'Crosstalk' enables the two CMC to share and monitor faults within each CMC.

- A CMC can generate up to 10,000 different fault codes.

- The CMC can be a self-contained Line Replaceable Unit (LRU) or a software function.

Fault Classification

- Aircraft systems use warnings, cautions, and advisories to indicate faults.

- Warnings are RED visual indications accompanied by a continuous aural warning requiring immediate action.

- Cautions are AMBER visual displays with a single aural tone requiring immediate flight crew awareness.

- Advisories are AMBER visual indications with no aural tone that needs flight crew awareness.

- The CMS records faults by classification:

- Level A (Warnings)

- Level B (Cautions)

- Level C (Advisories)

- Airbus classification system:

- Class 1: warnings and cautions

- Class 2: advisory or system status notification

- Class 3: maintenance memos (not displayed to the flight crew)

Failure Fault Code Types

- Failure fault codes include:

- Hard failure

- Soft failure

- Failure warnings

- Maintenance messages

- Maintenance memos

- Hard failure: system performance change due to operating system, LRU component, or wiring failure.

- Soft failure: system or LRU failure with no performance change; caused by BITE failures or faults in non-essential components.

- Failure warnings: indications where the built-in test detects a fault condition.

- Maintenance messages: generated by a Central Maintenance Computer (CMC) for each fault type.

- Maintenance Memos: fault-tolerant LRU, sub-system, or board-level faults where FDEs or status messages do not display.

Built-in Test Equipment (BITE)

- Units monitored by the CMC contain Built‑in Test Equipment (BITE).

- BITE is installed in navigation, flight control and environmental control systems, among others.

- The term BITE includes:

- Detection of the Fault.

- Accommodation of the fault.

- Annunciation or logging of the fault.

- Almost all avionic systems have some built-in test system.

- BITE identifies and isolates faults within failed LRUs.

- Types of BITE tests:

- Interruptive or Manual BITE

- Automatic or Continuous BITE

- Power Up BITE

- Component Level BITE

- System Level BITE

- Multi-System Level BITE

Interruptive or Manual BITE

- Flight crew or engineer initiates the test on the system or Line Replaceable Unit (LRU) through a selection of a test switch or function.

Automatic or Continuous BITE

- The system or LRU carries out the test on, or as, an internal operating function and without initiation.

Power Up BITE

- An automatic BITE where the system, LRU, or function carries out the test as an internal operating function as a part of its power-up sequence.

Component Level BITE

- Limited to a specific LRU or component within a system.

- Indications include magnetic dolls eyes, gauges, LEDs, lamps, test values, and audible tones.

System Level BITE

- Defined for a specific system.

- Enabled by a switch or automatically.

- Interfacing with other systems, sensors, or interlocks may be required.

- Provides greater fault isolation than simple LRU BITE.

- Indications are the same as Component Level BITE with one added indication: Fault Code/Fault Message

Multi-system Level BITE

- Works across and interfaces with all required systems.

- Needs to be enabled through a switch or separate function.

- Interdependent switch positions, sensors, or interlocks need to be serviceable.

- Failures of correlated systems generate fault codes, messages, or indications in the system under test.

Multifunction Control Display Unit (MCDU)

- The CMC is accessed via Multifunction Control Display Units (MCDU) in the flight deck.

- Small aircraft may have one MCDU; larger aircraft have two or three.

- MCDUs enable flight crew or engineers to navigate the OBMS via on-screen menus.

- Users can view current/present faults, previous faults, upload/download databases, and initiate system BITEs.

- Menus provide specific information about each fault, such as the date and time of occurrence.

Operation

- The CMC displays its maintenance information on the CDU.

- Information is organized within a menu structure.

- Access to the CMC MENU can be inhibited by the flight phase.

CDU Menu

- Accessed by pushing the MENU key on the CDU.

- The CMC is accessed by selecting the button adjacent to CMC on the CDU screen.

- All CMC functions and data pages are accessible through the two pages of the CMC MENU.

- The first page supports line maintenance and aircraft turnaround.

- The second page supports extended maintenance and troubleshooting.

- The header shows which CMC is in control (CMC-L MENU or CMC-R MENU).

Message Pages

- Most fault data provided by the CMC is shown on Message (MSG) pages.

- These provide the same type of fault data.

- Data shown includes:

- CMC fault message

- Number of the CMC fault message

- ATA chapter

- Date and time of occurrence

- Flight leg during which the fault became active

- Equipment number

- Indication of whether the fault is active

- Activation flight phase

- Fault determination (hard, intermittent, non-determined, or N/A)

- Flight Deck Effect (FDE)

Flight Leg

- A flight leg starts with the aircraft on the ground when the first engine starts.

- If the engines are not shut down from the previous flight, the next flight leg starts when the last door goes from open to closed.

Present Leg Faults

- Provides information on flight deck effects (FDEs) and CMC fault messages recorded during the present flight leg.

- Includes:

- CMC fault messages recorded during the present flight leg

- FDEs correlated to recorded CMC fault messages

- Latched EICAS status messages (correlated or not)

- CMC fault messages correlated to latched EICAS status messages

Confidence Tests

- Used to ensure specific systems are functioning properly.

- System ground tests that are accessible to the flight crew.

EICAS Maintenance Pages

- Provides access to show an EICAS maintenance page on the lower EICAS display.

Ground Tests

- Starts BITE tests of aircraft systems and LRUs.

- The CMC transmits a signal to an LRU to start the BITE test.

- The LRU sends the test result to the CMC.

- The CMC displays the test result on the CDU.

Existing Faults

- Shows the systems with active CMC fault messages in ATA chapter sequence.

Fault History

- Provides information about CMC fault messages stored in the CMC's non-volatile memory (NVM).

- The CMC can store a maximum of 500 CMC fault messages.

Maintenance Access Terminal (MAT)

- An advanced maintenance data storage system.

- Boeing introduced the Maintenance Access Terminal (MAT).

- Airbus introduced the Onboard Maintenance Terminal (OMT).

- Maintenance personnel can directly access maintenance data and perform ground tests.

- The MAT allows access to ground tests, system configuration etc.

Aircraft Communications Addressing and Reporting System (ACARS)

- Data from the CMS can be relayed to ground stations via ACARS or ATIMS.

- These systems use a Central Management Unit (CMU) to gather data.

- The data is packaged and sent to the aircraft operators ground operation station for analysis and monitoring of the aircraft's performance.

- ACARS data is transmitted using VHF, HF radio, or satellite communications (SATCOM).

Data Loading

- A data loading system is an interface between aircraft computers and ground equipment.

- Data loading is used to update software and databases or retrieve aircraft system data.

- Data can be downloaded or staged onto an aircraft server or repository.

- The data can then be used by the engineer when they are changing Line Replaceable Units (LRUs) which require data loading of software to provide them full system functionality.

- Data sources:

- Disc

- Pen-drive

- Through the airport network

- On a maintenance laptop

Disc Drive Unit

- Used on older aircraft types.

- Can operate in automatic or manual mode.

- The manual mode is only used to download data, while the automatic mode is used to both view and download data.

- The disc used must contain specific configuration information.

- A Multipurpose Disk Drive Unit (MDDU) may be used. Also, if a MDDU is not installed, uploading and downloading functions can be performed through a connector by using a portable data loader.

Multipurpose Disk Drive Unit (MDDU)

- Contains:

- An electronic unit with power supply, input/output, and CPU/Floppy Disk Drive Control boards.

- A Disk Drive installed on shock mounts.

- A Window with a 16-character alphanumerical LCD display.

- The data support is a 3.5-inch double-face, high-density disc (1.44 megabytes).

- This disc is in MS-DOS format.

Uploading

- Aircraft system computers use the loading system to update their database or modify parts of their operational software.

- Uploading is a data transfer from the repository or another media to the target hardware.

- Uploading can be carried out:

- From the repository to an aircraft computer

- From a dedicated source (CD, DVD) to the repository

- Directly from a CD/DVD to an aircraft computer

- Used to load new software or update software per service bulletin or airworthiness directive.

Downloading

- A downloading procedure is a data transfer from a computer to a storage media.

- The operator must select the file(s) to download and then the storage media.

Software Repository or File Server

- Media containing software loaded onto aircraft computers are kept onboard the aircraft in these locations.

- Contains a copy of the loads and batch files running on the aircraft.

- Repository capacity is typically set at 10 gigabytes.

- Only accessible by the Data Load and Configuration System (DLCS) for read and write functions.

- The Repository management function allows the addition or deletion of software.

New Technology Uploading and Downloading\Staging and Loading

- The latest types of aircraft use varied and different systems and methods to stage, configure, and load software.

- Airbus uses the Data Loading and Configuration System (DLCS).

- Boeing uses a Core Network and Crew Information System (CIS) to stage and load LRU and Line Replaceable Modules (LRM).

- Software and other LRU manufacturers will have their own systems to carry out this function.

- Staging software (Boeing) or Uploading (Airbus) describes how system software is brought onto the aircraft and securely stored.

- Data Loading (Boeing) or Software download (Airbus) is getting the operational configuration and airline modifiable software onto the LRU or LRM either by batch files or individual Loadable Software Airplane Parts (LSAP) loads.

Software Maintenance Tool (SMT)

- An application used on a maintenance laptop to manually stage the software on the aircraft.

- An On-board Data Load Function (ODLF) is used to load the software onto the LRU or LRM.

- Staging systems manage all data loading and configuration functions through their networks.

- Access to SMT is via the Maintenance Laptop onboard computer only.

Central Maintenance Computer (CMC) Sub-functions

- These four sub-functions must be carried out:

- Data Loading Management for up/down data loading procedures

- Aircraft Configuration Monitoring

- Repository (onboard software database) Management

- Software Pin Programming (SPP) Management

DLCS Interfaces (A380)

- The Data Load and Configuration System (DLCS) has an application hosted in the Aircraft network server units.

- This DLCS application is used to manage software data loading and configuration.

- The DLCS application stores and retrieves software to/from the Repository.

- The DLCS applications can be connected to the e-Logbook and to the aircraft documentation to ease maintenance procedures.

Human Machine Interfaces (HMIs) and CMC access Interface for Data Loading

- HMIs is principally an Airbus term where other manufacturers simply refer to the interface device in hand.

- HMIs used to control the DLCS:

- CAPT and F/O Onboard Information Terminals (OITs)

- The Onboard Maintenance Terminal (OMT)

- The Portable Multipurpose Access Terminal (PMAT)

- Other aircraft Interfaces can include

- Connection of a Maintenance Laptop (either wired or Wireless)

- The Aircraft Primary Display System

- Use of an Electronic Flight Bag

- Use of an Attendant Panel (where CMC listed cabin faults are present)

- Use of a Maintenance Access Terminal (MAT)

- Using the Onboard Data Load Function (ODLF) via a Maintenance Laptop (ML) requires turning the Ground Test Switch into the Data Load Enable position.

CMCS - Main Menu Selections

- The Central Maintenance Computing Function (CMCF) menus supply access to the following functions:

- Line maintenance

- Extended maintenance

- Other functions

- Help

- Report

MAT Main Menu Bar

- The ONBOARD MAINTENANCE selection from the Maintenance Access Terminal (MAT) main menu display will cause the CMCF main menu bar to show at the top of the MAT display.

- These are the selections available on this menu:

- INBOUND FLIGHT DECK EFFECTS

- EXISTING FLIGHT DECK EFFECTS

- GROUND TESTS

- SYSTEM CONFIGURATION

SYSTEM CONFIGURATION Selection

- The SYSTEM CONFIGURATION selection gives access to configuration data for system LRUs.

- This data includes hardware and software part numbers.

EXTENDED MAINTENANCE - MAT Main Menu Selection

- The EXTENDED MAINTENANCE selection supplies access to functions performed when more time is needed such as during overnight maintenance.

- These are the selections available on this menu:

- PRESENT LEG FAULTS

- EXISTING FAULTS

- FAULT HISTORY

- DATA LOAD

- HARD DRIVE SOFTWARE PART NUMBER MANAGEMENT

- MAINTENANCE PLANNING

- MAINTENANCE ENABLE/DISABLE

- EXIT MAINTENANCE

- The DATA LOAD selection is used to load LRU software.

System Configuration Box

- The system configuration selection dialog box shows ATA chapters and ATA system names for access to hardware and software configuration information for different LRUs and LRMs in the ATA systems.

- The system configuration dialog box shows:

- Dialog box title

- List box title

- Number of items

- List box

- Buttons

- The title of the list box is the ATA chapter number and system selected from the system configuration selection dialog box.

- The total number of LRM/LRU items shows at the top of the list box.

Configuration Data

- The configuration data identifiers are:

- Hardware part number

- Software #n part number

- LRU part number

- Serial number

- Options

- Other item

- Configuration data shows to the right of the configuration data identifiers.

Data Loading - General

- This is an introduction to the DATA LOAD screens that maintenance personnel will use to load software into specific systems or LRUs on the aircraft.

- This screen allows the user to monitor and start the data load function.

- The Destination Selection Screen allows the user to select the destination systems and LRUs that require data loading.

- The Source Selection Screen allows the user to select the source of the software and the specific files to be loaded.

Electronic Library System (ELS)

- The Electronic Library System (ELS) provides flight crew and maintenance personnel with timely access to necessary information.

- The system provides flight crew, maintenance engineers, and cabin crew with instantaneous access to the operational manuals, procedures, and navigation charts.

- In addition to timely access to the information, flight crews also have enhanced avionics functionality due to ELS mass storage capabilities. Besides maintenance personnel benefit because the On‑board Maintenance Systems (OMS) are combined with the Electronic Library System (ELS) in an integrated maintenance and fault-reporting environment.

- Types of user manuals included:

- A/C Maintenance Manual

- Quick Reference Handbook (QRH)

- Electronic Checklists

- Operations Manual

- Rotor Flight Manual

Basic Electronic Library System Architecture

- A typical system consists of a monochromatic active-matrix Liquid Crystal Display (LCD), an avionics-quality optical disk drive, an ARINC 744A printer, and a workstation platform.

- The user input device to the LCD consists of a capacitive touch screen overlay on the display surface.

- Systems utilise an Electronic Flight Bag (EFB), which is part of a Crew Information System (CIS), which both flight crew and engineers can access.

- Flight crew access their desired information by simply touching the display screen in the appropriate Graphic User Interface (GUI) menu tab areas.

- Input systems can include a keyboard.

Electronic Flight Bag Systems

- An Electronic Flight Bag (EFB) is an electronic information management device that helps flight crews perform flight management tasks more easily and efficiently with less paper.

- Provides onboard library capability and comprehensive functionality.

- Functionality includes access to video, the Onboard Maintenance System (OMS), the Onboard Data Load (ODL) functionality, and the Onboard Software Management (OSM).

Classes of Electronic Flight Bag (EFB)

- Electronic Flight Bags (EFBs) are divided into three hardware classes and three software types.

Hardware Classes:

- Class 1

- Class 2

- Class 3 Software Types:

- Type A

- Type B

- Type C

Printing System

- The flight compartment printing system supplies high-speed hard copy text and graphics.

- Located in the flight deck at the rear of the centre pedestal, or sometimes under the flight interphone handset. Also, some aircraft types have two flight deck printers, with each having dedicated functions.

Inputs to the Printer

- Central Maintenance Control (CMC) fault information can be printed.

- Systems that report to the printer:

- Central Maintenance Computer System (CMCS)

- Aircraft Condition Monitoring System (ACMS)

- ARINC Communications Addressing and Reporting System (ACARS)

- The Information System

- Captain electronic flight bag (EFB) electronic unit (EU)

- Integrated Modular Avionics suite systems

- Controller Pilot Data Link Computer CPDLC

The Flight Deck Printing System

- Gives a paper copy of data such as:

- Airplane system messages

- Charts

- Weather briefings

- Reports

- Faults

- General

- Print commands can come from:

- Captain or first officer EFB

- Maintenance laptop

- A Multifunction Display (MFD)

Printer Controls and Indications

- Push and hold the SLEW switch to advance the paper.

- The green MSG LED comes on when a message is received.

- Push the ALRT RST (Alert Reset) switch to reset the MSG LED.

- Push the REPT (Repeat) switch to print out the last printed message again.

- Push the TEST switch to start a self-test.

- If the test passes, a test pattern prints out.

- If the test fails, the amber FAULT LED comes on.

- The amber FAULT LED turns on if:

- A self-test is started and fails

- The front door is opened

- The printer is out of paper

- The paper indicator shows the amount of paper that remains in the printer.

Printer Servicing

- A yellow light appears when the paper supply is low.

- Use the release lever on the aft right side to move the handset cradle aft.

- Use the printer door latch to open the printer.

- Holders on each side of the printer hold the paper roll in place.

- The paper bar guides the paper out of the paper slot.

Introduction to Structure Monitoring

- Damage tolerance is the ability of an aircraft structure to sustain damage, without catastrophic failure, until the component can be repaired or replaced.

- Types of damage:

- Stress corrosion

- Cracks

- Accidental damage

- Impact damage

- Delamination

- Dis-bonding

- Water ingress

- Damage due to loads/strain

- Damage tolerance, or safety by inspection, was developed as a design philosophy in the 1970s as an improvement on the fail-safe principle for structural deterioration.

- Damage tolerant structures are designed to sustain cracks without catastrophic failure until detected in scheduled inspections.

- Structural health monitoring (SHM) involves sensors integrated into the aircraft structure for continuous or periodic inspection.

- SHM enables operators to identify the initiation and growth of damage in situ.

Structure Health Monitoring (SHM)

- SHM is a key enabling technology to ensure the integrity of future aircraft structures.

- SHM can help in increasing the structural allowable limits, removing conservatism in current designs. Besides it will reduce structural weight leading to reduced acquisition and maintenance costs.

Fatigue

- All components experience normal wear and tear due to repeated flight cycles.

- Structural components may develop cracks that can eventually fail.

- It is important to monitor and record the level of fatigue imposed on an aircraft structure.

- Methods to assist in SHM:

- Fatigue meters

- Strain gauges

- Intelligent Skins

Fatigue Meters

- Used to record overall, accumulated stress levels on aircraft.

- Can be stand alone or part of a system with external sensors.

- External sensors allow for real-time monitoring and can indicate when the aircraft nears or exceeds design limits.

Strain Gauges

- May be used to monitor stress levels on specific aircraft structures.

- Measure the deformation or strain caused by stress acting upon the component.

- If we replace one of the resistors in a balanced Wheatstone bridge with a wire strain gauge, the resistance will be a function of the deformation of the material.

- Measuring the resistance will give an indication of the deformation and, hence the stress applied. This can be used to indicate loading to aircraft systems and indicated to the pilot. The values will also be used for recording accumulated values.

Intelligent Skins

- Constructed with fibre optic sensors embedded in the material.

- The ability to conduct light will change as the fibres are stretched or damaged.

- The control unit senses changes in the light transmitted and interprets the strain on the material.

- Normally limited to composite materials.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.