Podcast

Questions and Answers

Which fuselage type relies on numerous structural elements like bulkheads, frames, longerons, and stringers to support the skin?

Which fuselage type relies on numerous structural elements like bulkheads, frames, longerons, and stringers to support the skin?

- Semi-monocoque type (correct)

- Truss type

- Monocoque type

- Pratt truss

In a Warren truss fuselage construction, what happens to the members when the load is reversed?

In a Warren truss fuselage construction, what happens to the members when the load is reversed?

- All members carry only compression.

- All members carry only tension.

- The load is distributed evenly among all members.

- Members switch from carrying tension to compression, and vice versa. (correct)

Why do pressurized aircraft commonly utilize semi-monocoque construction?

Why do pressurized aircraft commonly utilize semi-monocoque construction?

- To better distribute stresses caused by pressurization and metal fatigue. (correct)

- To reduce the weight of the aircraft.

- To improve aerodynamic efficiency.

- To simplify the manufacturing process.

Which of the following is a primary purpose of applying sealant to an aircraft fuselage?

Which of the following is a primary purpose of applying sealant to an aircraft fuselage?

In which type of seal is a bead of sealant placed between two overlapping pieces of metal?

In which type of seal is a bead of sealant placed between two overlapping pieces of metal?

What is the primary purpose of reinforcing the structure around cutouts for doors and windows in an aircraft fuselage?

What is the primary purpose of reinforcing the structure around cutouts for doors and windows in an aircraft fuselage?

Which method is typically used to attach the vertical fin to the fuselage?

Which method is typically used to attach the vertical fin to the fuselage?

What is the primary function of the upper, middle, and lower spars within an engine pylon structure?

What is the primary function of the upper, middle, and lower spars within an engine pylon structure?

Why are wheel wells designed as strong, structural, box-like enclosures?

Why are wheel wells designed as strong, structural, box-like enclosures?

What is the main purpose of seat tracks in an aircraft cabin?

What is the main purpose of seat tracks in an aircraft cabin?

How are aircraft seats typically secured to seat tracks?

How are aircraft seats typically secured to seat tracks?

What is the function of ball-mats in a cargo loading system?

What is the function of ball-mats in a cargo loading system?

What is the purpose of an Anti-Roll-Out (ARO) device in a cargo loading system?

What is the purpose of an Anti-Roll-Out (ARO) device in a cargo loading system?

According to ICAO Annex 6, what is a requirement for the flight crew compartment door on large passenger-carrying airplanes?

According to ICAO Annex 6, what is a requirement for the flight crew compartment door on large passenger-carrying airplanes?

In the construction of the flight deck door, what is the purpose of the decompression and evacuation flap?

In the construction of the flight deck door, what is the purpose of the decompression and evacuation flap?

What precaution should be taken before opening any emergency exit door once the aircraft is on the ground?

What precaution should be taken before opening any emergency exit door once the aircraft is on the ground?

Concerning door seals functions, what is a primary purpose of inflatable door seals?

Concerning door seals functions, what is a primary purpose of inflatable door seals?

How do cargo doors typically differ from passenger main entry doors (MEDs) in terms of their opening mechanism?

How do cargo doors typically differ from passenger main entry doors (MEDs) in terms of their opening mechanism?

What is the purpose of witness ports on cargo doors?

What is the purpose of witness ports on cargo doors?

What is the typical location of the bulk cargo door, and how does it operate compared to other cargo doors?

What is the typical location of the bulk cargo door, and how does it operate compared to other cargo doors?

What feature is commonly included in flight deck windows to prevent ice build-up?

What feature is commonly included in flight deck windows to prevent ice build-up?

What is the purpose of the vent hole in the inner pane of a passenger window?

What is the purpose of the vent hole in the inner pane of a passenger window?

During a flight deck window inspection, what does delamination typically appear as?

During a flight deck window inspection, what does delamination typically appear as?

Why is it important to sand the entire window surface in both horizontal and vertical directions when repairing passenger windows?

Why is it important to sand the entire window surface in both horizontal and vertical directions when repairing passenger windows?

What is the key characteristic of a full cantilever wing design?

What is the key characteristic of a full cantilever wing design?

In wing construction, what is the primary purpose of the wing ribs?

In wing construction, what is the primary purpose of the wing ribs?

What is the main difference between a mono-spar and a multi-spar wing design?

What is the main difference between a mono-spar and a multi-spar wing design?

What does the term 'failsafe' mean in the context of wing spar construction?

What does the term 'failsafe' mean in the context of wing spar construction?

What is the function of check valves in the baffles of an integral fuel tank?

What is the function of check valves in the baffles of an integral fuel tank?

What should be checked when performing maintenance on an integral fuel tank access panel?

What should be checked when performing maintenance on an integral fuel tank access panel?

What is the main function of a pylon?

What is the main function of a pylon?

Where are high lift and drag devices typically attached to the wing structure?

Where are high lift and drag devices typically attached to the wing structure?

What is the function of the horizontal stabilizer?

What is the function of the horizontal stabilizer?

What is a stabilator?

What is a stabilator?

In a similar method to the wing aileron attachment, what is the location where the rudder and elevator attach?

In a similar method to the wing aileron attachment, what is the location where the rudder and elevator attach?

Where are ailerons attached on an aircraft?

Where are ailerons attached on an aircraft?

How is mass balancing accomplished on a control surface?

How is mass balancing accomplished on a control surface?

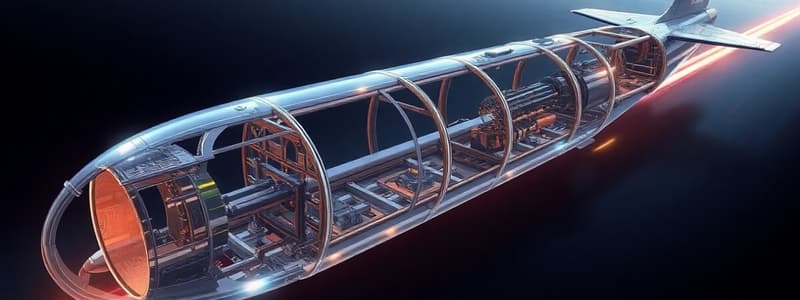

What are aircraft engines usually enclosed in?

What are aircraft engines usually enclosed in?

What materials are pylons typically constructed from?

What materials are pylons typically constructed from?

What is the primary role of a firewall in an aircraft?

What is the primary role of a firewall in an aircraft?

What material is commonly used for manufacturing engine mounts?

What material is commonly used for manufacturing engine mounts?

In a semi-monocoque fuselage, what is the primary benefit of having numerous structural elements like bulkheads, frames, longerons, and stringers?

In a semi-monocoque fuselage, what is the primary benefit of having numerous structural elements like bulkheads, frames, longerons, and stringers?

What differentiates a Pratt truss from a Warren truss in fuselage construction?

What differentiates a Pratt truss from a Warren truss in fuselage construction?

In a pressurized aircraft, what is the main reason for the extensive periodic inspections of the fuselage?

In a pressurized aircraft, what is the main reason for the extensive periodic inspections of the fuselage?

Why are two-part polysulfide sealants typically applied to aircraft fuselage joints during manufacturing?

Why are two-part polysulfide sealants typically applied to aircraft fuselage joints during manufacturing?

What is the primary purpose of a faying seal in aircraft construction?

What is the primary purpose of a faying seal in aircraft construction?

During the installation of a faying seal, what is the significance of smoothing the excess sealant that is squeezed out of the joint?

During the installation of a faying seal, what is the significance of smoothing the excess sealant that is squeezed out of the joint?

What is the main function of pressure seals used in the electrical and flying control cable runs?

What is the main function of pressure seals used in the electrical and flying control cable runs?

What is the role of strong fuselage frames or bulkheads in the area where the wings are attached?

What is the role of strong fuselage frames or bulkheads in the area where the wings are attached?

In the attachment of stabilizers (vertical and horizontal) to the fuselage, what is a key difference compared to wing attachments?

In the attachment of stabilizers (vertical and horizontal) to the fuselage, what is a key difference compared to wing attachments?

What is the purpose of the upper, middle, and lower spars within an engine pylon structure?

What is the purpose of the upper, middle, and lower spars within an engine pylon structure?

Why are seat tracks used in aircraft cabins?

Why are seat tracks used in aircraft cabins?

How do seat track fittings function to secure aircraft seats?

How do seat track fittings function to secure aircraft seats?

What is the primary purpose of a cargo loading system (CLS) in large transport aircraft?

What is the primary purpose of a cargo loading system (CLS) in large transport aircraft?

What is the function of the decompression and evacuation flap on a flight deck door?

What is the function of the decompression and evacuation flap on a flight deck door?

Regarding door seals, what is a primary purpose of inflatable door seals?

Regarding door seals, what is a primary purpose of inflatable door seals?

When repairing chips or scratches on passenger windows, why is it important to sand the entire window surface in both horizontal and vertical directions?

When repairing chips or scratches on passenger windows, why is it important to sand the entire window surface in both horizontal and vertical directions?

What is the significance of Jury Struts in wing design?

What is the significance of Jury Struts in wing design?

In wing construction, what is the primary role of the wing skin?

In wing construction, what is the primary role of the wing skin?

What is the purpose of wing ribs in wing construction?

What is the purpose of wing ribs in wing construction?

When performing maintenance on an integral fuel tank access panel, what should be checked?

When performing maintenance on an integral fuel tank access panel, what should be checked?

What is the purpose of a nacelle?

What is the purpose of a nacelle?

What is the purpose of the horizontal stabilizer?

What is the purpose of the horizontal stabilizer?

Where is the rudder attached on an aircraft?

Where is the rudder attached on an aircraft?

For the structural components of a pylon what transmits weight and lateral loads?

For the structural components of a pylon what transmits weight and lateral loads?

What is the primary reason for using a two-part polysulfide sealant during the manufacturing of an aircraft fuselage?

What is the primary reason for using a two-part polysulfide sealant during the manufacturing of an aircraft fuselage?

In the context of aircraft fuselage maintenance, what is the purpose of applying sealant to surface skin panels?

In the context of aircraft fuselage maintenance, what is the purpose of applying sealant to surface skin panels?

What is the main difference between the attachment of wings and stabilizers (vertical and horizontal) to the fuselage?

What is the main difference between the attachment of wings and stabilizers (vertical and horizontal) to the fuselage?

In seat track systems, how do the fittings on aircraft seats engage with the tracks to ensure secure attachment while allowing for adjustments?

In seat track systems, how do the fittings on aircraft seats engage with the tracks to ensure secure attachment while allowing for adjustments?

What is the significance of an Anti-Roll-Out (ARO) device in a cargo loading system?

What is the significance of an Anti-Roll-Out (ARO) device in a cargo loading system?

According to ICAO Annex 6, what measures are required for flight crew compartment doors on large passenger-carrying airplanes exceeding 45,500 kg or with more than 60 passenger seats?

According to ICAO Annex 6, what measures are required for flight crew compartment doors on large passenger-carrying airplanes exceeding 45,500 kg or with more than 60 passenger seats?

In the construction of the flight deck door, what role does the decompression and evacuation flap play?

In the construction of the flight deck door, what role does the decompression and evacuation flap play?

What action is of utmost importance prior to opening any emergency exit door after the aircraft has landed?

What action is of utmost importance prior to opening any emergency exit door after the aircraft has landed?

How do cargo doors typically differ from passenger main entry doors (MEDs) concerning their opening mechanism?

How do cargo doors typically differ from passenger main entry doors (MEDs) concerning their opening mechanism?

What is one of the key functions of the vent hole in the inner pane of a passenger window?

What is one of the key functions of the vent hole in the inner pane of a passenger window?

Why are wing spars generally oriented with the long dimension of their cross-section running up and down in the wing?

Why are wing spars generally oriented with the long dimension of their cross-section running up and down in the wing?

What is the purpose of check valves within the baffles of an integral fuel tank?

What is the purpose of check valves within the baffles of an integral fuel tank?

What is the function of a firewall in an aircraft?

What is the function of a firewall in an aircraft?

In what part of the wing structure are high lift and drag devices typically attached?

In what part of the wing structure are high lift and drag devices typically attached?

What is the primary function of the rudder on an aircraft?

What is the primary function of the rudder on an aircraft?

Compared to a fixed stabiliser, what is unique about the design of a stabilator?

Compared to a fixed stabiliser, what is unique about the design of a stabilator?

What is the purpose of mass balancing control surfaces on an aircraft?

What is the purpose of mass balancing control surfaces on an aircraft?

Why are aircraft engines typically enclosed in a nacelle?

Why are aircraft engines typically enclosed in a nacelle?

What is the function of the upper, middle, and lower spars within an engine pylon structure?

What is the function of the upper, middle, and lower spars within an engine pylon structure?

Flashcards

Fuselage

Fuselage

The primary body of an aircraft, housing crew, passengers, and cargo. It's designed for minimal aerodynamic resistance and structural integrity.

Truss Type Fuselage

Truss Type Fuselage

A fuselage construction type where members are joined to form a rigid structure.

Pratt Truss

Pratt Truss

A truss featuring wooden longerons and wire stays.

Warren Truss

Warren Truss

Signup and view all the flashcards

Stressed Skin Fuselage

Stressed Skin Fuselage

Signup and view all the flashcards

Pressurized Fuselage

Pressurized Fuselage

Signup and view all the flashcards

Polysulfide Sealant

Polysulfide Sealant

Signup and view all the flashcards

Faying Seal

Faying Seal

Signup and view all the flashcards

Fillet Seal

Fillet Seal

Signup and view all the flashcards

Cable Sealing

Cable Sealing

Signup and view all the flashcards

Wing Attachment

Wing Attachment

Signup and view all the flashcards

Stabilizer Attachment

Stabilizer Attachment

Signup and view all the flashcards

Pylon Attachment

Pylon Attachment

Signup and view all the flashcards

Landing Gear Attachment

Landing Gear Attachment

Signup and view all the flashcards

Seat Tracks

Seat Tracks

Signup and view all the flashcards

Seat Attachment Fittings

Seat Attachment Fittings

Signup and view all the flashcards

Cargo Loading System

Cargo Loading System

Signup and view all the flashcards

Transport Components

Transport Components

Signup and view all the flashcards

Guidance Components

Guidance Components

Signup and view all the flashcards

Restraining Components

Restraining Components

Signup and view all the flashcards

Anti-Roll-Out Device

Anti-Roll-Out Device

Signup and view all the flashcards

Main Entry Doors (MEDs)

Main Entry Doors (MEDs)

Signup and view all the flashcards

Service Doors

Service Doors

Signup and view all the flashcards

Cargo Doors

Cargo Doors

Signup and view all the flashcards

Plug-Type Door

Plug-Type Door

Signup and view all the flashcards

Door Warning System

Door Warning System

Signup and view all the flashcards

Door Seals

Door Seals

Signup and view all the flashcards

Door Locking Mechanism

Door Locking Mechanism

Signup and view all the flashcards

Flight Deck Door

Flight Deck Door

Signup and view all the flashcards

Emergency Exit Doors

Emergency Exit Doors

Signup and view all the flashcards

Emergency Escape Slide

Emergency Escape Slide

Signup and view all the flashcards

Safety Devices (Doors)

Safety Devices (Doors)

Signup and view all the flashcards

Cargo Doors

Cargo Doors

Signup and view all the flashcards

Bulk Cargo Door

Bulk Cargo Door

Signup and view all the flashcards

Aircraft Windows

Aircraft Windows

Signup and view all the flashcards

Passenger Windows

Passenger Windows

Signup and view all the flashcards

Flight Deck Windows

Flight Deck Windows

Signup and view all the flashcards

Delamination

Delamination

Signup and view all the flashcards

Wing Spar

Wing Spar

Signup and view all the flashcards

Wing Ribs

Wing Ribs

Signup and view all the flashcards

Wing Attach Fitting

Wing Attach Fitting

Signup and view all the flashcards

Wing Skin

Wing Skin

Signup and view all the flashcards

Rigid Removable Tank

Rigid Removable Tank

Signup and view all the flashcards

Bladder Fuel Tank

Bladder Fuel Tank

Signup and view all the flashcards

Integral Fuel Tank

Integral Fuel Tank

Signup and view all the flashcards

Wing Attachment Points

Wing Attachment Points

Signup and view all the flashcards

Pylon Function

Pylon Function

Signup and view all the flashcards

Nacelle

Nacelle

Signup and view all the flashcards

Horizontal Stabilizer

Horizontal Stabilizer

Signup and view all the flashcards

Vertical Stabilizer/Rudder

Vertical Stabilizer/Rudder

Signup and view all the flashcards

Study Notes

- The fuselage is the main body of the aircraft to which wings and tail are attached, providing space for crew, passengers, cargo, and controls.

- Aircraft fuselages need to be streamlined for capacity, and single-engine types usually have the engine in the nose with accessible accessories.

- Fuselages have attachment points for wings, tail, and landing gear that allow easy inspection, removal, repair, and replacement.

- Fuselages accommodate wings extending through them, and must protect occupants in a turnover, with enough emergency exits.

Typical Fuselage Sections

- Truss, monocoque, and semi-monocoque construction are typical aircraft fuselage sections.

- Most modern aircraft use semi-monocoque structures, with stressed skin supported by bulkheads, frames, longerons, and stringers for load distribution.

- Aircraft fuselages are tubular with an oval cross-section, where bulkheads and frames define shape, and longerons disperse longitudinal loads.

- Stringers attach the skin, reinforced cavities incorporate wings and landing gear (like APU), and door/window cutouts maintain load distribution.

Truss Type

- A truss joins several members for a rigid structure.

Pratt Truss

- Pratt trusses use wooden longerons, wood struts, and piano wire stays.

Warren Truss

- Warren trusses connect longerons with diagonal members, where all members carry either tension or compression.

- Smooth shapes are achieved using Pratt and Warren trusses with a non-load carrying superstructure covered in cloth.

- Truss structures are commonly made of steel, but also use wood, aluminum, or other materials.

Stressed Skin Fuselage

- Stressed skin construction carries all loads in the exterior skin and allows for smooth, aerodynamic shapes.

- Most metal aircraft use stressed skin, and air must be pumped into pressurized cabins.

Pressurized Fuselage

- Pressurization causes significant stress, so nearly all pressurized aircraft have a Semi-Monocoque construction.

- Pressurized fuselage structures undergo extensive periodic inspections, with modifications or redesigns as needed.

Pressurization Sealing

- Two-part polysulfide sealant is applied to withstand moisture ingress.

- Sealant is used between skin joints and seams, and on skin repairs and patches.

- Windscreens and windows use seals or gaskets, with sealant on external fairings.

- Sealing prevents corrosion and contains fuel in wing/body sections.

Faying Seal

- Faying refers to overlapping metal pieces, and sealant is placed between these pieces. Excess sealant is smoothed over the external portion of the joggle to provide a pressurization seal.

Fillet Seal

- A fillet seal is used when two pieces of metal are joined together, e.g. a stringer to the skin.

Electrical and Flying Control Cable Sealing

-

Electrical/flying control cable runs are sealed to protect against pressure leaks.

-

Electrical cables are sealed using rubber/silicon seals or sealant plates, while control cable runs use pressure seals that grip tightly.

-

Wings, stabilizers, engine pylons, and landing gear are attached to the fuselage.

-

Structure at major component attachment areas is reinforced, and attachment points vary.

-

Wings are attached either above or below the fuselage, which may be notched to accept a center wing section.

-

Strong fuselage frames or bulkheads are at wing attachment areas to carry loads and transfer them through longerons and beams.

-

Fittings or lugs on the frame mate and wing spar attach to bolts or fasteners.

Stabilisers (Vertical and Horizontal)

- Stabilizers attach similarly to wings, but the fuselage structure is stronger.

- Vertical fins typically use bolted fittings on a frame member or bulkhead.

- Attachments on the stabilizer are usually on the front and rear spars.

- Some horizontal stabilizers attach to the vertical stabilizer without additional fuselage attachments.

- Other horizontal stabilizers attach to strengthened fuselage frames, supported by forward and rear spars.

Pylons

- Engine pylons attach to the wing spars, usually built outwards and forward.

- Pylon members are called spars, transferring engine thrust to the airframe through the wing spars.

- A streamlined enclosure, the nacelle, houses the engine and has a firewall.

Undercarriage/Landing Gear

-

Landing gear is attached to the wings, specifically the main gear at the wing spar(s).

-

Landing gear strong enough to withstand landing forces when the aircraft is fully loaded.

-

Wing spars support the weight of the aircraft, and adaptive structures at the attach point support the gear/allow for retraction.

-

Wheel wells are strong, structural enclosures framed by heavy members and webs, with provision for door attachments.

-

Passenger and flight crew seats are secured to longitudinal tracks.

Seat Tracks

- Seat tracks attach with quick-release fasteners.

- Seat tracks are attached to the tops of the floor, with beams running down the length of the passenger cabin and flight deck

- Seat tracks enable pitch adjustments and reconfigurations of seat rows.

- Seat track fasteners also install cabin partitions (e.g., galley installations).

Seat Attachment

- Aircraft seats are usually secured to seat legs and to the track to provide adjustable spacing for legroom or modify the spacing between rows of seats.

- Track fittings enter the track through wide openings, slide fore or aft, and are locked by a spring-loaded pin.

- Threaded fasteners prevent rattling of the fittings.

Cargo Loading System

- Transport aircraft can carry passengers, cargo, or both.

- They typically have forward and aft main cargo compartments, with some having a smaller 'bulk' cargo compartment.

- Cargo is maneuvered using tracks, rollers, and Power Drive Units (PDUs), with ball-mats at entrances.

- Powered cargo systems allow load maneuvering inside.

- Seat track-type fasteners attach webbing nets.

Conveying and Locking Systems

- Cargo Loading Systems restrain, guide, and transport Unit Load Devices (ULD) during loading/unloading.

- Transport components include ball mats roller rails, and doorsill protectors.

- Guidance components include guide rails, side guides, and door guides.

- Restraining/locking components include cargo locks, outboard/centerline restraints, and end stops.

- Ball-mat area components allow ULD movement in any direction.

Anti-Roll-Out (ARO) Device

- The Anti-Roll-Out (ARO) device retracts when hit by a ULD base plate and lifts to prevent the ULD from falling out.

- ARO devices protect the door sill and aircraft, and must be retracted before the cargo door is closed.

Cargo Loading Operation

- Cargo is loaded and restrained using an electromechanical system comprising retractable driving/guide equipment.

- One person can carry out the loading operation.

- Containers are driven by retractable rollers and steered by guides, with load stops, locks, and lip guides for restraint.

- The system activates when the cargo door is open, electrical power is available, and the control panel switch is on.

Doors and Emergency Exits

- Modern aircraft have main entry, service, and cargo doors.

Introduction

- Doors are classified by their functions and operating mechanisms.

Plug Type Door

- Plug doors seal using pressure differences and are used on pressurized aircraft. The higher pressure forces the wedge-shaped door into the frame.

Non-plug Type Door

- Cargo doors open outward, preventing inward swing, and use locking mechanisms.

Passenger Main Entry Doors (MEDs)

- Aircraft Main Entry Doors (MEDs) are on the left and right sides of the fuselage, numbered from nose to tail.

- Left doors are mainly for passenger entry, while right doors are for galley servicing.

- Door warning systems visually indicate open or incorrectly latched doors.

- All MEDs are emergency exits, and door structure is similar to the fuselage.

Door Structure

- Aircraft doors are made from a riveted assembly, similar to the fuselage.

- The door structure houses opening, locking, and emergency mechanisms, and consists of a frame, beams, formers, and intercostals.

Door Frame Stops

- Pressure stop fittings on the door frame hold the door closed when pressurized via a pressure stop pin.

- The pressure stop fitting transmits pressure loads to the fuselage structure.

Door Seals

- Door seals stop pressurization air leaks (pressure seals) and reduce transmission of light, noise, and heat. They also improve aerodynamic smoothness.

- Door seals are flexible and held by adhesive, screws, or flanged channels, with some inflating when pressurized.

- Common seal shapes include bulb-type, diaphragm, flap-type, and multiform.

Door Locking Mechanism

- Mechanisms inside the door control locking and the evacuation system.

- Doors can be raised/lowered or cocked, and locking mechanisms vary.

- Main Entry Doors (MED) have locking mechanisms controlled by door handles. To open the door from the outside, push the latch button and rotate the handle in the direction of the door decal.

Flight Deck Door

- The Flight Deck Door separates the flight deck from the cabin. It is armored against intrusions.

- The flight crew can grant access via a toggle switch on the flight deck door panel.

Introduction

- Access to the flight deck through the door must be controlled, and limited to essential personnel.

- The door must remain locked unless there is a legitimate reason to open it.

Flight Deck Door Construction

- A decompression/evacuation flap is located in the lower part of the door.

- The door is always locked when closed and when the aircraft is powered.

- The door has a spyhole, keypad, and door handle on the cabin side.

Emergency Exit Doors

- Aircraft are required to have several escape doors or over-wing hatches for passenger evacuation.

- The required number depends on passenger capacity.

- All emergency exit doors in the main entry area have an emergency escape slide.

- Precautions must be taken to ensure the disarming of the escape slide before opening the door on the ground.

- A cabin pressure indicator should ensure the cabin pressure is not too high before opening the door.

Emergency Escape Slide

- Main Entry Doors (MED) have fittings to attach an emergency escape slide.

- The slide is gas-inflated, stored inside the door, and activated by a girt bar.

- The girt bar mechanism operates via a mode selector lever (Armed/Disarmed).

Safety Devices

- Safety devices prevent inadvertent operation of emergency escape slides, which include safety pins into to mode selector lever

- Safety gags prevent movement of the actuators during maintenance.

- Doors to pressurized areas have proximity sensors to indicate the open/closed and locked position.

Cargo Doors

- Cargo doors load/unload freight and equipment quickly

- Forward, aft, and bulk cargo doors are installed, with nose/side cargo doors on some aircraft.

- The bulk cargo door has an opening for loose luggage, etc.

- Electrically, hydraulically, or manually operated forward, aft, and side cargo doors open outward.

- The bulk cargo door, however, opens inward and is manual.

- The bulk cargo door is manually operated.

Cargo Door Structure

- Aircraft cargo doors are constructed similarly to Main Entry Doors (MED), but larger.

Cargo Door Locking Mechanism

- Cargo doors are non-plug type doors and open outward.

- Locking hooks inside the door engage around door pins, pulling it closed.

- A latching mechanism rotates around pins on the fuselage frame, securing the door.

- A seal around the door perimeter seals the opening

Cargo Door Operation

- Electrical, hydraulic, or manual systems control cargo doors, with control panels outside and inside the cargo area.

- Interior and exterior control switches are used.

Bulk Cargo Door

- The bulk cargo door is generally on the right side of the aircraft, behind the aft cargo door and allows access to the bulk cargo compartment.

- It is a plug type, manually opened, and hinges along the top with guide rollers/stops.

- Hinge arms rotate the door, with a counterbalance or snubber.

Door Safety Devices

- Proximity devices ensure that doors are securely locked.

- Each door has proximity devices to indicate it is latched and closed.

Introduction

- All windows allow maximum visibility and must hold cabin pressure. Flight deck windows also protect against bird impact and ice.

Window Composition

- Small aircraft have single-pane acrylic windows and windshields.

- Transport aircraft have passenger/flight deck windows. On transport aircraft Passenger cabin windows are fixed-plug type made of acrylic plastic.

Passenger Windows

- Most passenger windows have two layers of plastic. A third non-structural pane mounted in the interior panel, protects the inner window pane and reduces noise.

- A retainer ring with nuts/bolts or spring clips installs cabin windows, and frames are riveted to the fuselage.

- The panes of of glass are designed to hold differential pressure.

- Proper cleaning prevents damage.

- The inner pane of the window has a small vent hole in the centre which ensures same pressure between the panes as the cabin pressure.

Flight Deck Windows

- Six flight deck windows are located on the forward section of most modern aircraft.

- Two forward windows are "windshields", and side windows can slide open.

- Transport aircraft flight deck windows are constructed from laminations of tempered glass and plastic.

- A conductive lamination heats the window for impact resistance and anti-icing.

- Sliding windows are located on the side of the flight deck and are used as emergency exits.

Construction of A320 Flight Deck Window

- Fixed windows and number three and sliding windows number two are composed of stretched acrylic glass on A320s.

- Sliding windows are installed from inside using rails.

- A silicon seal bonds the windows to the frame.

The Openable/Sliding Window

- The openable/sliding windows provide a visual outlet and emergency escape route for the crew. It can be opened or closed, using a handle that operates a drive cable and drive screw to move the window.

- The window is locked in the full closed position by a latching handle when in the full position by four latches.

- An alert switch at the top of the window provides flight indication that the window is opened.

Flight Deck Window Inspection

-

Delamination, bubbles, chips, cracking, and scratches are types of damage found.

-

Delamination is the separation of layers, appearing shiny is seen as a flat bubble.

-

Small bubbles in the vinyl are not dangerous but may indicate heater control issues. The windshield must be replaced if bubbles decrease visual quality.

-

Chips occur when material is removed from the surface of the windowpane.

-

The windshield should be replaced if there are cracks in the glass or vinyl, especially if they prevent vision, or scratches more than 0.002 in (0.051 mm) in depth.

Passenger Window Inspection

- Passenger windows checked for crazing, cracking, chipping, scratches, and in-plane cracking.

- Crazing has frequent fissures, cracks can extend at all angles, and scratches displace material.

- Chips either have shell-type circular edges or sharp 'V' shape.

- Removal/replacement occur if damage exceeds limits per the Aircraft Maintenance Manual (AMM).

Window Repairs

- Allowable repairs include grinding/polishing to remove surface damage.

- Removal of window damage is achieved using sandpaper, polishing, or buffing.

Wing Construction

- Wing construction types are mono-spar, multi-spar, and box beam.

Introduction

- Wings consist of left/right wing box sections and a center wing box, which supports the fuselage and is enclosed within the fuselage structure.

Construction

- Wings attach to the fuselage, designed to produce lift.

- Wing design depends on size, weight, use of aircraft, speed, rate of climb, and landing.

- Wings are identified as left and right by their location relative to the flight crew.

- Most wings are full cantilever, constructed without the need for external bracing.

- Smaller aircraft wings use external supports. Fairings reduce drag, and Jury Struts help control strut movement.

- The most common material is aluminum, but modern aircraft use composite materials.

Example of Wing Construction Showing Front and Rear Spar plus Ribs and Stringers

- Spars/stringers run spanwise, and ribs/formers/bulkheads run chordwise.

- Wing construction is based on one of three designs: mono-spar, multi-spar, and box beam.

- The mono-spar wing uses one main longitudinal member, and ribs/bulkheads supply contour.

- The Multi-spar wing utilises more than one main longitudinal member.

Typical Box Beam Structure

- The box beam wing uses two main members with connecting bulkheads.

Wing Spars

- Wing spars are the main structural members, running parallel to the aircraft's lateral axis.

- They are usually connected to the fuselage by fittings, beams, or a truss.

- Spars can be made of metal, wood, or composite materials dependent on the design.

- Most spars are rectangular, composites or combined materials used to increase strength while reduce weight.

- Commonly used I-beam spars have top/bottom "caps" and a vertical "web".

Example of Truss Design Spar

- Failsafe design is built into the spar web.

Spar with Failsafe Construction

- False spars do not extend the entire length of the wing.

Wing Ribs

- Wing ribs combine with spars and stringers to make up the framework, also used in ailerons, elevators, rudders, and stabilizers.

- Wing ribs extend from the wing leading edge to the rear spar or the wing trailing edge.

- The wing ribs provide the wing with its cambered shape and transmit the loads from the wing skins and stringers to the wing spars.

Basic Structural Components of a Wing, Spars, and Ribs

- False ribs do not span the entire wing chord.

Wing Roots and Tips

- Wing attach fittings are at the inboard end of the wing spars. The interface between the wing and fuselage is usually covered with a fairing.

- A wing tip is often removable and bolted to the outboard end.

Wing Skin

- Wing skin carries flight/ground loads with spars and ribs.

Example of Full Cantilever Wing Section

- "Stressed skin design" means skin shares the load.

- Skin can be made from fabric, wood, or aluminum.

- Chemically milled aluminum provides varied thickness.

- Honeycomb structured wing panels are often used as skin.

Fuel Storage

- Rigid removable, flexible bladder, and integral fuel tanks are the different types of fuel storage tanks.

Introduction

- The location, size, shape, and construction of fuel tanks vary.

Rigid Removable Tanks

- Simple rigid tanks are strapped to the airframe.

- They are often riveted or welded, with baffles.

- Rigid removable tanks must be supported by the airframe and held in place with padded straps to prevent movement and chafing in flight.

- Many early tanks were made of a thin steel sheet called 'terneplate'.

- Removable fuel tanks are often located in the wings.

Wing Fuel Tank Bay with Straps

- Being able to remove and repair, or replace a fuel tank can be a great convenience in the event of a leak or malfunction. Fuel tank repairs must be done in accordance with the manufacturer’s specifications.

- It is critical to follow safety procedures during welding repairs.

Bladder Fuel Tanks

- Reinforced flexible material makes a bladder fuel tank, used instead of a rigid tank.

- Bladder tanks must be attached to the structure with clips or other fastening devices.

- It should lie smoothly in the bay to avoid fuel contaminants getting blocked from settling into the sump.

- Bladder tanks are usually wiped on the inside with clean engine oil, when stored for extended periods, to avoid drying and cracking.

Integral Fuel Tanks

- Part of the wings or fuselage structure is sealed with a fuel-resistant sealant to form the fuel tank.

- This type of tank is known as ‘integral fuel tanks’ and are commonly used in wing structures and sealed wings are known as "wet wings".

Typical Fuel Tank Wing Structure with Baffles and Check Valves

-

Wing ribs/box beam members act as baffles, with additional baffles added.

-

Integral fuel tanks must have access panels for inspection/repairs.

-

Large aircraft have numerous access panels on the bottom surface of the wings.

-

Panels are sealed with an O-ring and aluminum gasket, and are tightened with screws.

-

During maintenance strict safety procedures must be followed.

-

All fuel must be emptied and fuel vapors must be purged from the tank.

-

Landing gear, pylons, and flight controls attach to the structure.

-

Wing attachment points fit flight control surfaces, landing gear, and engine pylons.

Landing Gear

- Landing gear is attached to the wings; and attachment points are at the wing rear spar(s).

- Wings spars are designed to be strong.

Pylons

- The Pylon’s function is to carry the engine and are usually designed to be aerodynamic

- Structures also have various forms, sizes, and designs.

Wing Rear Spar Showing Landing Gear Attachment Points

- Pylons and nacelles attach to wings.

- The pylon structure is built out and forward from the forward wing spars.

- Wing spars transfer engine thrust loads to the airframe; and nacelles attach to pylons.

Nacelle

- Nacelles reduce drag, and house the engine and its components.

Control Surfaces and High Lift/Drag Devices

- High lift and drag devices, including ailerons, slats, spoilers, and speed brakes, attach to the front and rear wing spars.

Aileron

- Each outboard aileron is supported by hinge support fittings attached to the wing trailing edge rib structure. Hinge fittings on the aileron front spar attach to the wing support fittings. The aileron actuator and reaction linkages attach to wing rear spar fittings and aileron front spar fittings.

Spoilers/Speedbrakes

- The spoiler attachment fittings consist of hinge fittings and attachment angles are either located on the aft face of the wing rear spar, or on the aft face of the spoiler support beam.

Trailing Edge (TE) Flaps

- The Trailing Edge (TE) flap attachment fittings consist of two pairs of flap tracks, one pair for each flap assembly which are each bolted to the wing rear spar and other support members.

- Both tracks of the outboard flaps are attached to the lower edges of special wing ribs, forward of the wing rear spar.

Leading Edge (LE) Flaps and Slats

-

Leading Edge (LE) flap attachment fittings consist of the hinge fittings mounted along the forward edge of the LE structure, and the actuator mountings on the forward face of the wing front spar.

-

The LE slat attachment fittings consist of the brackets which support the guide rollers and the actuators. All of which are attached to the forward face of the wing front spar.

-

Stabilizers steady the aircraft in flight and are fixed aerodynamic surfaces at the empennage (aft fuselage). They stabilize the aircraft

-

They consist of a horizontal stabilizer (with elevators) and a vertical stabilizer (with a rudder).

-

The vertical stabilizer (vertical fin) is a fixed aerofoil that extends vertically from the empennage. and provides directional control.

-

Vertical stabilizers are similar between all aircraft as they are all fixed surfaces.

-

Vertical stabilisers are mounted via solid anchor points on the aft fuselage along the centre line of the longitudinal axis.

-

The vertical stabiliser is attached to the fuselage by high tension bolts through the fin-to-body attach angles.

Horizontal Stabilizer

-

The horizontal stabilizer extends laterally from both sides of the empennage.

-

Elevators on the stabilizer adjust pitch stability for the aircraft. Formats are:

-

Fixed stabilizers (“tailplane”) are fixed aerofoils which are bolted to the fuselage.

-

Stabilators pivot up and down from a hinge point.

-

Variable incidence tailplanes enable one-piece moveable tail.

-

Construction of stabilizers mirrors wing design via spars, ribs, stringers, and skin while transmitting stresses to the fuselage.

-

Flight controls attach on hinges to move, and the rudder and elevator attach to the stabilizer rear spar similar to the wing aileron.

-

The horizontal rear spar has structural components and hydraulic actuators to secure the elevator.

-

Elevator attachments to the Horizontal Stabiliser allow movement via fittings (similar for rudders).

-

Flight control surfaces are aerodynamic devices that control aircraft attitude.

-

Primary controls manage yaw, pitch, and roll.

-

Secondary controls are the speed brake and flap system.

-

Flight controls are attached to robust aircraft structures because they are subject to major aerodynamic stresses.

Construction and Attachment

- Ailerons attach to the wing rear spars.

- Elevators attach to horizontal stabilizer rear spars.

- Rudders attach to vertical stabilizer rear spars.

- Spoilers attach to wing rear spars.

- Flap tracks attach to wing rear spars.

- Leading Edge (LE) slat tracks attach to wing front spars.

- Connections use high-strength bolts.

Trailing Edge (TE) Flaps

- Trailing edge attachment points fits flaps, ailerons, and spoilers.

Spoilers

- Spoilers attach to the wing rear spar area with bolts and bushes. At the centre hinge area is a bracket for the hydraulic actuator.

Leading Edge (LE) Flaps and Slats

-

The Leading Edge (LE) devices are slats or variable camber flaps connected by actuators.

-

The surfaces are structurally strengthened where there are trim tab attachments. Flight control surfaces are similar in construction to the wing with spars, ribs, and skin.

-

Safety precautions are relevant when working with flight control surfaces, as they move rapidly when they are actuated.

-

The movement prevents inadvertent retraction

-

Maintenance should be carried out in communication.

-

The balancing of flight controls eliminates any flutter, with forces depending on airspeed/surface area.

-

Aerodynamic (Horn) and Mass Balancing are methods of balancing.

Aerodynamic (Horn) Balancing

- The aerodynamic balance extends controls out ahead of the hinge line to utilize airflow. Airflow reduces the input force needed to deflect the surface.

Mass (Static) Balancing

- Mass balance adds weight to the leading edge. The Centre of Gravity (CG) of the flight control makes flutter less likely and requires rebalancing after repair/repaint.

Mass Balancing Process

-

Trailing edges locate in the support notch

-

Movement is guided by a spirit level

-

The surface is removed from the aircraft and set in a horizontal position where adjustable balance weights are added to the surface until the scale reads zero.

-

This involves jig A-frames, scales, and sliding weights.

-

Nacelles and pylons support engine connections to the aircraft, which serve as a vibration and heat barrier.

Introduction

-

Arrangement of engines influences the aircraft.

-

Pylons, or struts, typically have a frame and skin structure of lightweight/high-strength materials. It divided into a primary and secondary structure. The pylon assembly consists of a torque box, firewall & fire seal, fairings, strut drains, fan cowl support beam, and engine attachment fittings.

-

Primary structures are mainly made of spars, ribs, stiffeners, and side panels.

-

The following attachment points on the wing: 2 forward pylon attachment fittings, and 1 aft pylon attachment fitting.

-

Nacelles streamlines the engine and accessories, mounts, structural members, firewalls, and skin/cowling.

-

The framework has lengthwise/horizontal/vertical members, and is covered with aluminum/magnesium alloy or stainless steel/titanium alloys.

-

Noise-reduction reduces engine noise.

-

Fan Cowl Supports and firewalls provides a low-drag aerodynamic profile.

-

Firewalls prevent hazardous material from passing through to other parts of the aircraft.

-

The firewall is a flameproof bulkhead that separates the engine compartment from the rest of the aircraft and is required via regulations.

Firewalls

-

Current Certification Specifications (CS25.1191 – Firewalls) state that each firewall and shroud must be fireproof, constructed so that no hazardous quantity of liquid, gas, or flame can pass from the compartment created by the firewall or shroud to other parts of the aircraft.

-

Gas turbine engines operate and are constructed from heat-resistant materials.

-

Fire seals are fitted and firewalls are present in components.

-

Fire shield and heat blankets are a fire and heat barrier that must be examined for cracks, tears, and burned areas.

-

An engine mount connects the engine to the frame for smooth flying.

-

Engine mounts are constructed of steel. They connects the engine with the fuselage, suppresses the vibrations and distributes them safely to the whole aircraft structure for a smooth flight.

Mounts for Reciprocating Engines

- Aircraft equipped with reciprocating engines use a welded steel tubing.

- The engine mount ring houses dynafocal mounts angled toward the Centre of Gravity (CG).

- Shock mounts have rubber and metal parts so the rubber supports the engine, with metal snubbers limit movement from unusual stress.

- Dynafocal engine mounts have the mounting pad angled to point to the Centre of Gravity (CG) of the engine’s mass.

Mounts for Turbofan Engines

-

Turbofan-engine mounts support the engine and transfer loads.

-

Vibration isolator engine mounts support the power plants and isolate the aircraft structure, each supported by forward and aft mounts

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.