Podcast

Questions and Answers

In Fused Deposition Modeling (FDM), the filament is melted in a ______ that moves in XY direction.

In Fused Deposition Modeling (FDM), the filament is melted in a ______ that moves in XY direction.

nozzle

In FDM, molten plastic is then extruded from the ______ and then deposited on the build platform.

In FDM, molten plastic is then extruded from the ______ and then deposited on the build platform.

nozzle

In FDM, the molten plastic is deposited on the ______ in layers until the part is finished.

In FDM, the molten plastic is deposited on the ______ in layers until the part is finished.

build platform

In Stereolithography (SLA), the ______ traces the path of the geometry/pattern that is being produced.

In Stereolithography (SLA), the ______ traces the path of the geometry/pattern that is being produced.

In SLA, the resin hardens after ______ exposure.

In SLA, the resin hardens after ______ exposure.

Fused Deposition Modeling (FDM) is a type of ______ technology.

Fused Deposition Modeling (FDM) is a type of ______ technology.

In FDM, the plastic is melted and deposited in ______ on the build platform.

In FDM, the plastic is melted and deposited in ______ on the build platform.

The build platform is a part of the ______ process in FDM.

The build platform is a part of the ______ process in FDM.

Stereolithography (SLA) is a type of ______ technology.

Stereolithography (SLA) is a type of ______ technology.

Additive Manufacturing refers to a class of technologies that can automatically construct physical models from ______ data.

Additive Manufacturing refers to a class of technologies that can automatically construct physical models from ______ data.

Additive Manufacturing is synonymous to ______ printing.

Additive Manufacturing is synonymous to ______ printing.

The first techniques for rapid prototyping became available in the late ______.

The first techniques for rapid prototyping became available in the late ______.

In Additive Manufacturing, physical models are formed by adding ______ layer by layer.

In Additive Manufacturing, physical models are formed by adding ______ layer by layer.

The application of Additive Manufacturing in the ______ industry is one of the many uses of this technology.

The application of Additive Manufacturing in the ______ industry is one of the many uses of this technology.

The ______ stage of the Additive Manufacturing process involves creating a geometric model.

The ______ stage of the Additive Manufacturing process involves creating a geometric model.

Additive Manufacturing is used in ______ applications such as creating prosthetics and implants.

Additive Manufacturing is used in ______ applications such as creating prosthetics and implants.

The ______ stage of the Additive Manufacturing process involves slicing the model into thin cross-sectional layers.

The ______ stage of the Additive Manufacturing process involves slicing the model into thin cross-sectional layers.

The software ______ is used for Geometric Modeling.

The software ______ is used for Geometric Modeling.

According to the Wohlers Report 2021, ______ percent of Additive Manufacturing applications are for end use parts.

According to the Wohlers Report 2021, ______ percent of Additive Manufacturing applications are for end use parts.

Tessellation is a process of dividing a ______ into smaller units.

Tessellation is a process of dividing a ______ into smaller units.

The process of ______ involves dividing a 3D model into 2D layers.

The process of ______ involves dividing a 3D model into 2D layers.

RP machines build one layer at a time during the process of ______ of Layers.

RP machines build one layer at a time during the process of ______ of Layers.

The final step in 3D printing is ______ and Finishing.

The final step in 3D printing is ______ and Finishing.

Fusion360 is a software used for ______ Modeling.

Fusion360 is a software used for ______ Modeling.

SolidWorks is a software used for ______ Modeling.

SolidWorks is a software used for ______ Modeling.

The University of the Philippines ______ is the department that teaches Geometric Modeling.

The University of the Philippines ______ is the department that teaches Geometric Modeling.

The department that teaches Geometric Modeling is the ______ of Mechanical Engineering.

The department that teaches Geometric Modeling is the ______ of Mechanical Engineering.

Laminated Object Manufacturing is a type of ______ process.

Laminated Object Manufacturing is a type of ______ process.

Electron Beam Melting is a process wherein parts are formed by melting ______ powder layer per layer with an electron beam.

Electron Beam Melting is a process wherein parts are formed by melting ______ powder layer per layer with an electron beam.

Titanium alloys are widely used in Electron Beam Melting technology which makes it a suitable ______ for medical implant market.

Titanium alloys are widely used in Electron Beam Melting technology which makes it a suitable ______ for medical implant market.

Electron Beam Melting has a ______ layer thickness of at least 0.05mm.

Electron Beam Melting has a ______ layer thickness of at least 0.05mm.

Electron Beam Melting is used in the production of ______ parts.

Electron Beam Melting is used in the production of ______ parts.

High quality ______ melting enables high material properties in Electron Beam Melting.

High quality ______ melting enables high material properties in Electron Beam Melting.

The vacuum requirement in Electron Beam Melting entails additional ______.

The vacuum requirement in Electron Beam Melting entails additional ______.

Electron Beam Melting is applicable to ______, ceramics, and composites.

Electron Beam Melting is applicable to ______, ceramics, and composites.

Electron Beam Melting is a ______ process.

Electron Beam Melting is a ______ process.

The ______ is lowered and a new layer of powder is spread.

The ______ is lowered and a new layer of powder is spread.

SLS polyamide (nylon) material enables full functional ______ production.

SLS polyamide (nylon) material enables full functional ______ production.

High shrinkage ratios can result in ______, bending, or dimensional inaccuracy.

High shrinkage ratios can result in ______, bending, or dimensional inaccuracy.

Rubber like parts can be manufactured directly from ______ for seals and sealing elements.

Rubber like parts can be manufactured directly from ______ for seals and sealing elements.

SLS feature details are not precise as in ______ parts.

SLS feature details are not precise as in ______ parts.

Glass-filled nylon is resistant to high ______ and chemical environments.

Glass-filled nylon is resistant to high ______ and chemical environments.

The surface finish of SLS parts are not good as ______ parts.

The surface finish of SLS parts are not good as ______ parts.

A layer of ______ is placed in the fabrication bed.

A layer of ______ is placed in the fabrication bed.

High power laser ______ the powder that it traced.

High power laser ______ the powder that it traced.

What is the main advantage of Laminated Object Manufacturing (LOM) in terms of material costs?

What is the main advantage of Laminated Object Manufacturing (LOM) in terms of material costs?

What is the main limitation of Laminated Object Manufacturing (LOM) in terms of part complexity?

What is the main limitation of Laminated Object Manufacturing (LOM) in terms of part complexity?

What is the main difference between SLA and SLS in terms of surface finish?

What is the main difference between SLA and SLS in terms of surface finish?

What is the main advantage of using SLS polyamide (nylon) material for production?

What is the main advantage of using SLS polyamide (nylon) material for production?

What is a characteristic of SLS polyamide (nylon) material?

What is a characteristic of SLS polyamide (nylon) material?

What is the main application of Lompoxy material?

What is the main application of Lompoxy material?

What is a material used in Laminated Object Manufacturing?

What is a material used in Laminated Object Manufacturing?

What is the main advantage of using rubber-like parts manufactured directly from SLS for high-temperature applications?

What is the main advantage of using rubber-like parts manufactured directly from SLS for high-temperature applications?

What is a difference between SLA and SLS surface finish?

What is a difference between SLA and SLS surface finish?

What is the main property of Glass-filled nylon material?

What is the main property of Glass-filled nylon material?

What is an application of 3D printed rubber-like parts?

What is an application of 3D printed rubber-like parts?

What is a characteristic of Lompoxy material?

What is a characteristic of Lompoxy material?

What is a limitation of SLS parts?

What is a limitation of SLS parts?

What is a step in the Electron Beam Melting process?

What is a step in the Electron Beam Melting process?

What is the main advantage of using Electron Beam Melting (EBM) in the medical implant market?

What is the main advantage of using Electron Beam Melting (EBM) in the medical implant market?

What is the minimum layer thickness in Electron Beam Melting (EBM)?

What is the minimum layer thickness in Electron Beam Melting (EBM)?

What is the primary characteristic of Electron Beam Melting (EBM) that enables high material properties?

What is the primary characteristic of Electron Beam Melting (EBM) that enables high material properties?

What is the primary application of Electron Beam Melting (EBM)?

What is the primary application of Electron Beam Melting (EBM)?

What is the main disadvantage of Electron Beam Melting (EBM)?

What is the main disadvantage of Electron Beam Melting (EBM)?

What type of materials can be used with Electron Beam Melting (EBM)?

What type of materials can be used with Electron Beam Melting (EBM)?

What is the characteristic of Electron Beam Melting (EBM) that makes it suitable for precise parts?

What is the characteristic of Electron Beam Melting (EBM) that makes it suitable for precise parts?

What is a characteristic of Glass-filled nylon SLS material?

What is a characteristic of Glass-filled nylon SLS material?

What is the main advantage of SLS polyamide (nylon) material in prototype production?

What is the main advantage of SLS polyamide (nylon) material in prototype production?

What is the difference between SLA and SLS parts in terms of surface finish?

What is the difference between SLA and SLS parts in terms of surface finish?

What is the application of SLS 3D printed rubber-like parts?

What is the application of SLS 3D printed rubber-like parts?

What is the process of Laminated Object Manufacturing?

What is the process of Laminated Object Manufacturing?

What is the advantage of SLS material in terms of temperature resistance?

What is the advantage of SLS material in terms of temperature resistance?

What is the difference between SLS and SLA parts in terms of feature details?

What is the difference between SLS and SLA parts in terms of feature details?

What is a characteristic of SLS polyamide (nylon) material?

What is a characteristic of SLS polyamide (nylon) material?

What is a limitation of Laminated Object Manufacturing process?

What is a limitation of Laminated Object Manufacturing process?

How does the surface finish of SLA parts compare to SLS parts?

How does the surface finish of SLA parts compare to SLS parts?

What is a potential application of 3D printed rubber-like parts?

What is a potential application of 3D printed rubber-like parts?

What is a characteristic of Lompoxy material?

What is a characteristic of Lompoxy material?

What is a common use of Lompoxy material?

What is a common use of Lompoxy material?

What is a process used in Laminated Object Manufacturing?

What is a process used in Laminated Object Manufacturing?

What is a key advantage of using SLS polyamide (nylon) material for production?

What is a key advantage of using SLS polyamide (nylon) material for production?

What is a characteristic of SLS polyamide (nylon) material?

What is a characteristic of SLS polyamide (nylon) material?

What is the main difference between SLA and SLS in terms of surface finish?

What is the main difference between SLA and SLS in terms of surface finish?

What is the main advantage of Laminated Object Manufacturing (LOM) in terms of material costs?

What is the main advantage of Laminated Object Manufacturing (LOM) in terms of material costs?

What is a limitation of Laminated Object Manufacturing (LOM) in terms of part complexity?

What is a limitation of Laminated Object Manufacturing (LOM) in terms of part complexity?

What are rubber-like parts manufactured from, suitable for high-temperature applications?

What are rubber-like parts manufactured from, suitable for high-temperature applications?

What is a characteristic of Lompoxy material?

What is a characteristic of Lompoxy material?

What is a use of Lompoxy material?

What is a use of Lompoxy material?

What is a characteristic of SLS polyamide (nylon) material in terms of surface finish?

What is a characteristic of SLS polyamide (nylon) material in terms of surface finish?

What is an advantage of using SLS polyamide (nylon) material for production?

What is an advantage of using SLS polyamide (nylon) material for production?

Flashcards are hidden until you start studying

Study Notes

Additive Manufacturing (AM)

- Refers to a class of technologies that can automatically construct physical models from Computer-Aided Design (CAD) data.

- Also known as 3D printing.

- Formed by adding materials layer by layer.

Why is AM relevant?

- Sales: 3%

- Metal tooling: 4%

- Polymer pattern: 7%

- Functional prototypes: 25%

- Jigs and fixtures: 7%

- Cosmetic models: 10%

- End-use parts: 32%

- Education and research: 12%

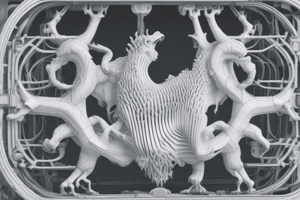

Applications of AM

- Art

- Dental applications

- Automotive industry

- Bioengineering

- Aerospace applications

- Fashion

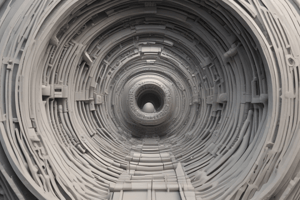

Additive Manufacturing Process

-

- Geometric Modeling

-

- Tessellation of the geometric model

-

- Slicing of the model into thin cross-sectional layers

-

- Constructing the model

-

- Finishing and cleaning

Geometric Modeling

- Software used: Pro/Engineer, Fusion360, SolidWorks

Constructing of Layers

- RP machines build one layer at a time

Fused Deposition Modeling (FDM)

- Filament is melted in a nozzle that moves in the XY direction

- Molten plastic is extruded from the nozzle and deposited on the build platform in layers

- Requires support material

Stereolithography (SLA)

- Laser traces the path of the geometry/pattern that is being produced

- Resin hardens after laser exposure

- Build platform descends, and the process repeats

Selective Laser Sintering (SLS)

- Layer of powder is placed in the fabrication bed

- High-power laser fuses the powder that it traced

- Fabrication bed is then lowered, and a new layer of powder is spread

SLS Characteristics

- Enables full functional prototype production

- Surface finish is not good as SLA parts

- Additional surface finish can be applied

- Glass-filled nylon is resistant to high temperature and chemical environments

- High shrinkage ratios can result in dimensional inaccuracy

- Rubber-like parts can be manufactured directly from polymer

Laminated Object Manufacturing (LOM)

- No specific details mentioned

Electron Beam Melting (EBM)

- Process wherein parts are formed by melting metal powder layer per layer with an electron beam in a high vacuum

- Suitable for medical implant market due to the use of titanium alloys

- Characteristics:

- No need for extra heat treatment

- High surface quality

- Applicable to metals, ceramics, and composites

- Precise process

- Minimum layer thickness at 0.05mm

- Used in medical implants, aerospace, and automotive parts

Selective Laser Sintering (SLS)

- Low cost due to readily available raw material

- Relatively large parts can be made, as no chemical reaction is necessary

- Production of complex parts is difficult

- There may be a fire problem when the working zone gets too hot

- No need for additional processing

- No need for additional support

- Very easy to use

Laminated Object Manufacturing (LOM)

- The most common used material is still paper

- Low cost due to readily available raw material

- Relatively large parts can be made, as no chemical reaction is necessary

- Production of complex parts is difficult

- Fast as laser only traces the contour and does not trace the whole cross section

- Parts can be used immediately after processing

Electron Beam Melting (EBM)

- It is a process where parts are formed by melting metal powder layer per layer with an electron beam in a high vacuum

- Titanium alloys are widely used in this technology, making it suitable for medical implant market

- High quality vacuum melting enables high material properties

- No need for extra heat treatment

- Applicable to metals, ceramics, and composites

- Precise process

- Minimum layer thickness at 0.05mm

Stereolithography (SLA)

- No information provided

Fused Deposition Modeling (FDM)

- It is a solid-based rapid prototyping method that extrudes material, layer-by-layer, to build a model

- Support material is required

- Filament is melted in a nozzle that moves in XY direction

- Molten plastic is then extruded from the nozzle and deposited on the build platform in layers

- Used for producing functional prototypes, models, and end-use parts

Additive Manufacturing (AM)

- Refers to a class of technologies that can automatically construct physical models from Computer-Aided Design (CAD) data

- In this method, physical models are formed by adding materials layer by layer

- The first techniques for rapid prototyping became available in the late 1980s

- Synonymous to 3D printing

- Applications include sales, metal tooling, polymer patterns, functional prototypes, jigs and fixtures, cosmetic models, end-use parts, education research, and others

Additive Manufacturing vs Machining

- No information provided

Additive Manufacturing Process

-

- Geometric Modelling

-

- Tessellation of the geometric model

-

- Slicing of the model into thin cross-sectional layers

-

- Constructing the model

-

- Finishing and cleaning

Applications of Additive Manufacturing

- Art

- Automotive industry

- Bioengineering

- Aerospace applications

- Fashion

- Dental applications

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.