Podcast

Questions and Answers

What is the primary advantage of universal motors in household appliances?

What is the primary advantage of universal motors in household appliances?

- Low cost of production

- High power-to-weight ratio and speed control capabilities (correct)

- Low power consumption

- Small size and compact design

What is the principle behind the operation of a universal motor?

What is the principle behind the operation of a universal motor?

- Mechanical friction

- Electrostatic induction

- Electromagnetic induction (correct)

- Thermal energy conversion

What is the function of the commutator in a universal motor?

What is the function of the commutator in a universal motor?

- To increase the torque generated by the motor

- To generate a magnetic field

- To regulate the speed of the motor

- To reverse the direction of current flow in the rotor windings (correct)

What is the purpose of the brushes in a universal motor?

What is the purpose of the brushes in a universal motor?

During start-up, what happens when power is supplied to the universal motor?

During start-up, what happens when power is supplied to the universal motor?

What is the result of electromagnetic induction in a universal motor?

What is the result of electromagnetic induction in a universal motor?

What determines the direction of the torque generated by a universal motor?

What determines the direction of the torque generated by a universal motor?

How can the speed of a universal motor be controlled?

How can the speed of a universal motor be controlled?

What is a characteristic of universal motors that allows them to operate on both AC and DC power sources?

What is a characteristic of universal motors that allows them to operate on both AC and DC power sources?

What is the main difference between the stator and rotor in a universal motor?

What is the main difference between the stator and rotor in a universal motor?

Flashcards are hidden until you start studying

Study Notes

Classification of AC Motors

- AC motors are categorized based on various factors such as:

- Construction

- Speed control method

- Type of rotor

- Application

Classification Based on Construction

- Synchronous Motors:

- Rotor rotates at the same speed as the rotating magnetic field produced by the stator

- Used in applications where constant speed is required

- Induction Motors (Asynchronous Motors):

- Operate on the principle of electromagnetic induction

- Rotor rotates at a speed slightly less than the synchronous speed of the stator's rotating magnetic field

- Further classified into:

- Single-phase induction motors

- Three-phase induction motors

Classification Based on Rotor Type

- Squirrel Cage Rotor:

- The most common type of rotor in induction motors

- Consists of conductors (aluminum or copper bars) placed in slots of the rotor laminations and short-circuited at both ends by end rings

- Wound Rotor (Slip Ring) Motor:

- Rotor windings are not short-circuited, but are connected to slip rings and external resistors

- Allows for external control of rotor resistance, enabling speed control and improved starting torque

Classification Based on Speed Control Method

- Fixed Speed Motors:

- Operate at a constant speed determined by the frequency of the power supply and the number of poles

- Variable Speed Motors:

- Speed can be varied through methods such as:

- Variable Frequency Drives (VFDs)

- Variable Voltage Control

- Pole Changing Motors

- Speed can be varied through methods such as:

Classification Based on Application

- General Purpose Motors:

- Used in a wide range of applications such as fans, pumps, conveyors, and compressors

- Special Purpose Motors:

- Designed for specific applications, such as:

- Servo Motors

- Stepper Motors

- Hazardous Location Motors

- Fractional Horsepower Motors

- Designed for specific applications, such as:

Construction of AC Motors

- AC motors convert electrical energy into mechanical energy

- Main components of an AC motor:

- Stator

- Rotor

- Bearings

Types of AC Motors

- Induction Motor:

- Operates on the principle of electromagnetic induction

- Simple, rugged, and widely used in various industrial and domestic applications

- Synchronous Motor:

- Operates at a constant speed determined by the frequency of the AC power supply and the number of poles

- Used in applications where precise speed control is required

- Single-Phase Induction Motor:

- Designed to operate on single-phase AC power supplies

- Commonly used in household appliances like fans, pumps, and washing machines

- Three-Phase Induction Motor:

- More efficient and has higher power ratings compared to single-phase motors

- Widely used in industrial applications such as pumps, compressors, conveyor systems, and machine tools

Principle of Working and Characteristics of 3-Phase Induction Motors

- Principle of Working:

- Rotating Magnetic Field (RMF)

- Induced Voltage

- Interaction of Fields

- Torque Production

- Characteristics:

- Self-Starting

- Speed Regulation

- Efficiency

- Torque Characteristics

- Maintenance

- Size and Cost

Applications of AC Motors

- AC motors are widely used in various applications such as:

- Industrial Machinery

- HVAC Systems

- Household Appliances

- Electric Vehicles (EVs)

- Power Tools

- Pumps and Compressors

- Renewable Energy

- Transportation Systems

- Automation and Robotics

- Medical Equipment

Starting and Braking of 3-Phase Induction Motors

- Starting methods:

- Direct-on-Line (DOL) Starter

- Star-Delta Starter

- Auto-transformer Starter

- Soft Starter

- Variable Frequency Drive (VFD)

- Braking methods:

- Coasting or Free-wheeling

- Dynamic Braking

- Regenerative Braking (for VFDs)

- Plugging (Reverse Braking)

Classification of Single-Phase Induction Motors

- Based on starting method:

- Split-phase Induction Motors

- Capacitor Start-Induction Run (CSIR) Motors

- Capacitor Start-Capacitor Run (CSCR) Motors

- Based on rotor construction:

- Squirrel Cage Rotor Motors

- Wound Rotor Motors

- Based on type of enclosure:

- Open Drip-proof (ODP) Motors

- Totally Enclosed Fan Cooled (TEFC) Motors

- Totally Enclosed Non-Ventilated (TENV) Motors

- Based on output power and size:

- Fractional horsepower to several horsepower

Construction of Single-Phase Induction Motors

- Stator:

- Laminated core made of thin steel sheets

- Windings

- Rotor:

- Squirrel cage rotor

- Wound rotor

- Bearings:

- Ball or roller bearings depending on the size and application of the motor### Single-Phase Induction Motor

- The stator winding is typically made of copper wire and is wound around the core slots.

- The winding arrangement could be a single-layer or double-layer depending on the motor design.

- The main winding is responsible for generating a magnetic field when energized and is connected directly to the power supply.

- Some single-phase induction motors may also have an auxiliary winding, which is often smaller and has more turns than the main winding.

Rotor Types

- The rotor is the rotating part of the motor and can be of two types: squirrel-cage rotor or wound rotor.

- The squirrel-cage rotor consists of a cylindrical laminated steel core with conductive bars or short-circuited aluminum or copper conductors placed in the slots on the surface.

- The wound rotor has windings similar to those of the stator winding and is connected through slip rings, allowing external resistors or other control elements to be connected.

Bearing System and Housing

- The rotor is supported by bearings, which allow it to rotate smoothly.

- The stator and rotor assemblies are enclosed within a housing, typically made of cast iron or aluminum, to protect them from environmental factors and provide mechanical support.

- End bells are fitted at both ends of the motor to house the bearings and provide mounting points.

Ventilation System

- Ventilation slots or fans are often incorporated into the housing to allow airflow through the motor and dissipate heat generated during operation.

Starting Mechanism

- A starting mechanism such as a centrifugal switch or a starting capacitor may be added to the motor to improve starting performance.

Principle of Operation

- The single-phase induction motor operates on the principle of electromagnetic induction.

- The stator has a set of windings that are energized by a single-phase AC power supply, creating a rotating magnetic field.

- A starting mechanism is necessary to overcome the limitation of the single-phase system.

Working

- The stator windings produce a magnetic field that interacts with the rotor, inducing currents in the rotor bars.

- The interaction between the stator's rotating magnetic field and the rotor's induced magnetic field causes the rotor to rotate.

Applications

- Single-phase induction motors are commonly used in various applications, including household appliances, small industrial applications, office equipment, HVAC systems, agricultural machinery, and power tools.

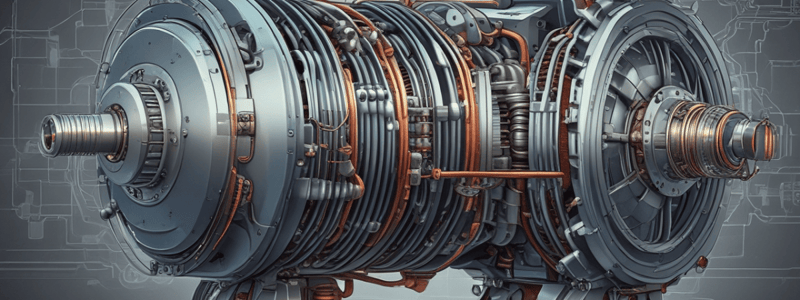

Universal Motor

Principle of Operation

- The universal motor operates on the principle of electromagnetic induction.

- It can run on both AC and DC power sources due to its unique design.

Components

- Stator: The stationary part of the motor, consisting of a series of windings or coils wound around iron poles.

- Rotor: The rotating part of the motor, typically made of a core with wire windings or conductive bars.

- Commutator: A split metal ring attached to the rotor shaft, divided into segments.

- Brushes: Carbon brushes that maintain electrical contact with the commutator segments.

Working

- When power is supplied to the motor, current flows through both the stator and rotor windings, creating a magnetic field that induces a magnetic field in the rotor.

- Electromagnetic induction occurs, inducing an electromotive force (EMF) in the rotor windings, generating a magnetic field that interacts with the stator's magnetic field.

Torque Generation and Speed Control

- The interaction between the magnetic fields produces a torque on the rotor, causing it to rotate.

- The speed of the universal motor can be controlled by varying the voltage or by using electronic speed control circuits.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.