Podcast

Questions and Answers

What is the purpose of converting a CAD model to STL format?

What is the purpose of converting a CAD model to STL format?

- To describe the model's geometry using triangular facets (correct)

- To simplify the model for easier printing

- To enhance the color of the model

- To create a detailed operational blueprint

Which step is not part of the AM process chain?

Which step is not part of the AM process chain?

- Build

- Machine setup

- Post-processing of part

- Material coating (correct)

Which aspect is crucial for design considerations in Additive Manufacturing?

Which aspect is crucial for design considerations in Additive Manufacturing?

- Part density

- Removal of supports (correct)

- Surface texture

- Color variation

What is an application area of AM that does not require conventional CAD modeling?

What is an application area of AM that does not require conventional CAD modeling?

Which factor is important for metal systems in Additive Manufacturing?

Which factor is important for metal systems in Additive Manufacturing?

Why is maintenance of equipment important in the AM process chain?

Why is maintenance of equipment important in the AM process chain?

What should be considered during the conceptualization phase of product design in AM?

What should be considered during the conceptualization phase of product design in AM?

Which of the following is an example of a variation among AM machines?

Which of the following is an example of a variation among AM machines?

What is the primary reason for using support structures in additive manufacturing?

What is the primary reason for using support structures in additive manufacturing?

Which statement best describes the cleanup stage in additive manufacturing?

Which statement best describes the cleanup stage in additive manufacturing?

What is one potential drawback of parts produced through additive manufacturing?

What is one potential drawback of parts produced through additive manufacturing?

In post-processing, what is one of the primary tasks that may be performed?

In post-processing, what is one of the primary tasks that may be performed?

What is the nominal layer thickness for most machines in additive manufacturing?

What is the nominal layer thickness for most machines in additive manufacturing?

How can the use of power tools in post-processing be beneficial?

How can the use of power tools in post-processing be beneficial?

Which of the following statements about layer thickness and build time is true?

Which of the following statements about layer thickness and build time is true?

What does anisotropic mean in the context of additive manufacturing materials?

What does anisotropic mean in the context of additive manufacturing materials?

Why might some applications require careful handling of additive manufactured parts?

Why might some applications require careful handling of additive manufactured parts?

What is a major advantage of photopolymer-based additive manufacturing systems?

What is a major advantage of photopolymer-based additive manufacturing systems?

What factor must be considered when post-processing materials involving heat?

What factor must be considered when post-processing materials involving heat?

Which statement about the materials used in additive manufacturing is correct?

Which statement about the materials used in additive manufacturing is correct?

Which aspect can often cause problems when fine details are included in a design?

Which aspect can often cause problems when fine details are included in a design?

What characteristic can make Zcorp parts somewhat unique in additive manufacturing?

What characteristic can make Zcorp parts somewhat unique in additive manufacturing?

Which is a common challenge when building parts with very fine details in additive manufacturing?

Which is a common challenge when building parts with very fine details in additive manufacturing?

How does the processing of materials as powder, molten material, or solid sheet affect additive manufacturing?

How does the processing of materials as powder, molten material, or solid sheet affect additive manufacturing?

What is a requirement for molten material systems during the melting and deposition process?

What is a requirement for molten material systems during the melting and deposition process?

Which method does NOT require the use of support structures?

Which method does NOT require the use of support structures?

What is a potential disadvantage when using paper-based systems in additive manufacturing?

What is a potential disadvantage when using paper-based systems in additive manufacturing?

What must be carefully monitored in some additive manufacturing machines?

What must be carefully monitored in some additive manufacturing machines?

Which of the following is NOT a design consideration for additive manufacturing?

Which of the following is NOT a design consideration for additive manufacturing?

What aspect is particularly important in electron beam melting and similar metal systems?

What aspect is particularly important in electron beam melting and similar metal systems?

In which application area is conventional CAD modeling typically NOT used?

In which application area is conventional CAD modeling typically NOT used?

Which of the following conditions should be avoided during material handling in additive manufacturing?

Which of the following conditions should be avoided during material handling in additive manufacturing?

What is a potential future trend in architectural modeling that has been mentioned?

What is a potential future trend in architectural modeling that has been mentioned?

What challenge is associated with certain additive manufacturing technologies?

What challenge is associated with certain additive manufacturing technologies?

What advancement is expected in future additive manufacturing processes?

What advancement is expected in future additive manufacturing processes?

Which of the following software applications is mentioned as being specifically designed for additive manufacturing?

Which of the following software applications is mentioned as being specifically designed for additive manufacturing?

What is a likely future need for direct digital manufacturing?

What is a likely future need for direct digital manufacturing?

Flashcards are hidden until you start studying

Study Notes

Eight Steps in AM

- Conceptualization and CAD: Ideas about product's look and function, ranging from text descriptions to 3D CAD models

- Conversion to STL: STL (STereoLithography) describes a CAD model's geometry using triangular facets; most CAD systems automate this conversion.

- Transfer to AM Machine and STL File Manipulation: The STL file is sent to the AM machine, the part is often separated from the build platform or excess material, support structures are added to prevent collapsing or warping during the building process.

- Machine Setup: AM machines require specific setup based on the materials and process

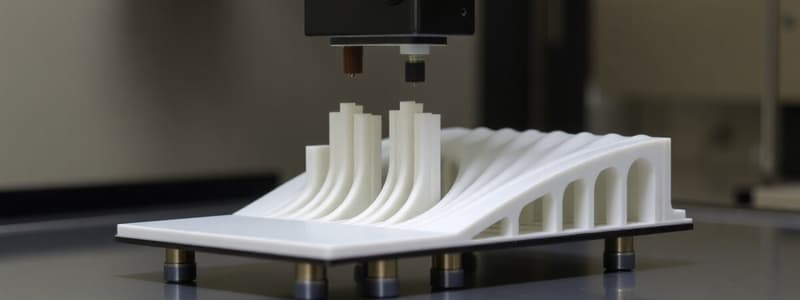

- Build: The AM machine builds the part layer by layer according to the STL file

- Part Removal and Cleanup: Removal of supports and excess material, may involve manual work and skill to avoid damaging the part

- Post-Processing: Finishing the part for application purposes, includes abrasive finishing, coatings, and may be application specific.

- Application: The part can be used following post-processing, but may exhibit different properties than traditionally manufactured parts due to AM processes.

Variations in AM Machines

- Layer Thickness: Most machines have a layer thickness around 0.1 mm, FDM machines typically use 0.254 mm, SL technology uses 0.05-0.1 mm; thicker layers build faster but are less precise.

- Fine Details: Fine details and thin walls can be problematic for some AM technologies, as the droplet size, laser diameter, or extrusion head limits resolution.

- Material Variations: Different materials require different processes, time, resources, and skill, affecting setup, build, and post-processing.

Types of AM Machines

- Photopolymer-Based Systems: Easy to set up, uses the same material for the part and support structures; offers good accuracy with thin layers, but has poor mechanical properties compared to other AM materials.

- Powder-Based Systems: No supports needed, deposits a bed of powder layer by layer; easy to set up for simple builds, Zcorp uses colored binder material to create colored parts

- Molten Material Systems: Requires support structures, supports can be automatically generated for droplet-based systems or manually added for extrusion processes.

- Solid Sheets: No support structures needed as the sheets are placed and cut; requires handling waste material, cleanup can be laborious.

Metal Systems

- Similar to polymer systems, but require consideration for:

- The use of substrates: Metal parts are often built on a substrate for support and stability

- Energy density: The energy needed to melt and fuse metal powder is high, influencing build speed and part quality

- Weight: Metal parts are heavier than plastic parts

- Accuracy: Metal AM can achieve high accuracy, but is influenced by energy density and cooling

- Speed: Metal builds are generally slower than plastic builds

Maintenance of Equipment

- AM machines often use fragile laser or printer technology, requiring careful monitoring and a clean, vibration free environment.

Materials Handling Issues

- Moisture and Light: Some materials are sensitive to moisture and light, requiring special handling and storage.

- Loading and Recycling: Material loading is often done offline using software, and some materials can be recycled.

Design for AM

- Part Orientation: To minimize support structures and optimize building time, consider the orientation of the part.

- Removal of Supports: Design parts with easily removable support structures to avoid damage to the finished part.

- Hollowing Out Parts: To reduce material usage and weight, consider hollowing out parts.

- Inclusion of Undercuts: Design parts avoiding features that require special support structures or post-processing, such as undercuts.

- Interlocking Features: Design parts with interlocking features to minimize the need for separate parts in assembly.

- Part Count Reduction: Explore ways to reduce the number of parts in an assembly by combining them into a single part.

- Identification Marking / Numbering: Design parts with integrated markings for easy identification.

Application Areas Beyond Conventional CAD modeling

- Medical Modeling: AM is used to create models from medical scans (CT, MRI, ultrasound) for surgical planning or anatomical studies.

- Reverse Engineering Data: Laser scanning technology can generate 3D models from existing physical objects for replication or analysis.

- Architectural Modeling: AM is used to create architectural models with textures, colors, and shapes that may not be replicable in the final design.

Future Considerations

- Layer Thickness and Regions: AM technologies may progress to thicker layers or processing regions instead of layers, improving speed and efficiency.

- Alternative File Formats: New file formats beyond STL may be required to describe parts volumetrically or hierarchically, enabling greater complexity in designs.

- Combined Processes: We can expect more complex AM machines integrating additive, subtractive, and robotic handling processes.

- Software Optimization: Software is constantly improving to optimize AM processing, including automated support generation and design for manufacturability.

- Direct Digital Manufacturing: As AM becomes more common, industry wide standardized software processes will be needed for wider adoption.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.