Podcast

Questions and Answers

What is the first step in the 3D printing process?

What is the first step in the 3D printing process?

Design Creation

In 3D printing, the 3D model file needs to be exported in a format compatible with 3D printing, such as STL or _____

In 3D printing, the 3D model file needs to be exported in a format compatible with 3D printing, such as STL or _____

OBJ

Which step comes after Printer Setup in the 3D printing process?

Which step comes after Printer Setup in the 3D printing process?

- Post-Processing

- Printing (correct)

- Quality Check

- File Preparation

In 3D printing, the final step is Post-Processing.

In 3D printing, the final step is Post-Processing.

Match the following 3D printing materials with their names:

Match the following 3D printing materials with their names:

What is the first step in the Molding process?

What is the first step in the Molding process?

Which step follows Material Injection/Pouring in the Molding process?

Which step follows Material Injection/Pouring in the Molding process?

In CNC machining, the CAD model is converted into a CAM program to generate _____

In CNC machining, the CAD model is converted into a CAM program to generate _____

A dry run in CNC machining involves cutting the material to form the desired part.

A dry run in CNC machining involves cutting the material to form the desired part.

Match the following CNC machining materials with their names:

Match the following CNC machining materials with their names:

Flashcards are hidden until you start studying

Study Notes

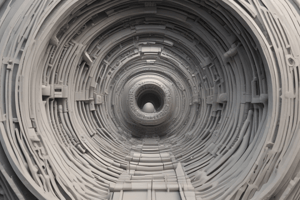

3D Printing

- 3D printing involves 7 steps: design creation, file preparation, slicing, printer setup, printing, post-processing, and quality check.

- Design creation involves creating a 3D model using CAD software or obtaining a pre-made model from online repositories.

- File preparation involves exporting the 3D model file in a format compatible with 3D printing (e.g., STL or OBJ).

- Slicing involves converting the 3D model into layers and generating a G-code file that the printer can interpret.

- Best materials for 3D printing include PLA, ABS, PETG, Nylon, TPU, Resin, Polycarbonate, PVA, and Carbon Fiber Infused Filaments.

Molding

- Molding involves 10 steps: design creation, mold fabrication, material preparation, mold setup, material injection/pouring, cooling, mold opening, part removal, post-processing, and quality inspection.

- Design creation involves creating a detailed design or model of the object to be molded using CAD software.

- Best materials for molding include Polyurethane, Epoxy, Aluminum, Steel, Acrylic, ABS, Polycarbonate, and PLA.

Vacuum Forming

- Vacuum forming involves 10 steps: design creation, mold fabrication, material preparation, heating, forming, cooling, mold removal, trimming, post-processing, and quality inspection.

- Design creation involves creating a detailed design or model of the object to be formed.

- Best materials for vacuum forming include Acrylic, PETG, ABS, Polycarbonate, High-impact polystyrene, PVC, Polyethylene, Polypropylene, Thermoplastic Polyurethane, and High-Density Polyethylene.

CNC

- CNC machining involves 10 steps: design creation, conversion to CNC program, machine setup, toolpath setup, dry run, machining, monitoring, part removal, post-processing, and quality inspection.

- Design creation involves creating a detailed CAD model of the part to be machined.

- Best materials for CNC machining include Aluminum, Steel, Brass, Titanium, Plastics, Copper, Stainless Steel, Carbon Fiber Reinforced Plastics, Tool Steel, and Magnesium.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.