Podcast

Questions and Answers

What is the recommended printing speed range for optimal accuracy?

What is the recommended printing speed range for optimal accuracy?

- 90-100mm/s

- 10-20mm/s

- 70-80mm/s

- 50-60mm/s (correct)

The nozzle diameter for the model is 0.3mm.

The nozzle diameter for the model is 0.3mm.

False (B)

What should the file name for the GCode in Cura only contain?

What should the file name for the GCode in Cura only contain?

English letters, underscore, and space

The diameter of the selected wire is _____mm.

The diameter of the selected wire is _____mm.

Match the following components with their corresponding sizes:

Match the following components with their corresponding sizes:

Which mode in Cura allows you to see the toolpath and check for issues before printing?

Which mode in Cura allows you to see the toolpath and check for issues before printing?

To enable uniform scaling in Cura, the lock in the scaling window should be clicked.

To enable uniform scaling in Cura, the lock in the scaling window should be clicked.

What driver needs to be installed for online printing with Cura?

What driver needs to be installed for online printing with Cura?

What is the factory default voltage setting for the 3D printer?

What is the factory default voltage setting for the 3D printer?

Filament should be inserted into the hotend before preheating.

Filament should be inserted into the hotend before preheating.

What temperature range is ideal for filament to flow properly through the hotend?

What temperature range is ideal for filament to flow properly through the hotend?

The main board wiring diagram is shown in Figure ___.

The main board wiring diagram is shown in Figure ___.

Match the components to their installation steps:

Match the components to their installation steps:

What should you do if you feel resistance while inserting the filament?

What should you do if you feel resistance while inserting the filament?

It is important to ensure that the filament reel is tangled before installation.

It is important to ensure that the filament reel is tangled before installation.

What can customers use to remove extruded filament from the nozzle tip before printing?

What can customers use to remove extruded filament from the nozzle tip before printing?

What is one recommendation for easier feeding of the filament?

What is one recommendation for easier feeding of the filament?

The DMSCREATE DP-X 3D printer can resume from outage when printing online.

The DMSCREATE DP-X 3D printer can resume from outage when printing online.

What should you do if the filament is leaking too much?

What should you do if the filament is leaking too much?

To ensure adhesion of the first layer, the print platform should be kept _____ and the heat bed temperature should match the filament.

To ensure adhesion of the first layer, the print platform should be kept _____ and the heat bed temperature should match the filament.

Match the troubleshooting issue with its potential cause:

Match the troubleshooting issue with its potential cause:

Which of the following is NOT mentioned as a reason for the first layer not adhering?

Which of the following is NOT mentioned as a reason for the first layer not adhering?

You should always open the cooling for the first layer when printing with ABS filament.

You should always open the cooling for the first layer when printing with ABS filament.

What is the recommended bottom layer print speed to ensure good adhesion?

What is the recommended bottom layer print speed to ensure good adhesion?

Which of the following is NOT a reason for gaps or hollows on the top layer of a printed model?

Which of the following is NOT a reason for gaps or hollows on the top layer of a printed model?

Setting the Fill value too low in the slicing software can cause gaps in the printed model.

Setting the Fill value too low in the slicing software can cause gaps in the printed model.

What is the first step in leveling the heat bed?

What is the first step in leveling the heat bed?

The nozzle should always be lower than the platform when leveling.

The nozzle should always be lower than the platform when leveling.

What should be checked if the print head is moving too fast?

What should be checked if the print head is moving too fast?

If the printing temperature is too high, it can lead to the model ___ because of melting.

If the printing temperature is too high, it can lead to the model ___ because of melting.

What file extensions can be loaded into Cura?

What file extensions can be loaded into Cura?

It is very important to ensure the flat portion of the model is well attached to the platform, so please use the ______ option after rotating the model.

It is very important to ensure the flat portion of the model is well attached to the platform, so please use the ______ option after rotating the model.

Match the issue with its possible solution:

Match the issue with its possible solution:

What is one consequence of setting the printing temperature too low?

What is one consequence of setting the printing temperature too low?

How can you zoom in or out in Cura?

How can you zoom in or out in Cura?

Match the following actions in Cura with their corresponding descriptions:

Match the following actions in Cura with their corresponding descriptions:

It is recommended to grease the rods and tighten nuts and bolts to prevent layer shifting.

It is recommended to grease the rods and tighten nuts and bolts to prevent layer shifting.

Name one reason for filament not extruding during the printing process.

Name one reason for filament not extruding during the printing process.

You should adjust the Z adjustable nut only once during the leveling process.

You should adjust the Z adjustable nut only once during the leveling process.

What should you do after loading a 3D model into Cura?

What should you do after loading a 3D model into Cura?

What could cause stripes or bulges on the surface during printing?

What could cause stripes or bulges on the surface during printing?

A high printing temperature can lead to wrinkles on the surface.

A high printing temperature can lead to wrinkles on the surface.

What is one potential cause of uneven extruding?

What is one potential cause of uneven extruding?

Remove the SD card and insert into ___ to check if Gcode files are readable.

Remove the SD card and insert into ___ to check if Gcode files are readable.

Match the printing issue with its potential cause:

Match the printing issue with its potential cause:

What is a possible solution to fix the issue of a touch screen not responding?

What is a possible solution to fix the issue of a touch screen not responding?

If the motor makes abnormal sounds, the wiring connections should be inspected.

If the motor makes abnormal sounds, the wiring connections should be inspected.

What should you do if a print abruptly stops halfway?

What should you do if a print abruptly stops halfway?

Which type of laser is primarily used for cutting, boring, and engraving?

Which type of laser is primarily used for cutting, boring, and engraving?

The Nd:YAG laser is primarily used for applications requiring low energy and high repetition.

The Nd:YAG laser is primarily used for applications requiring low energy and high repetition.

What is the classic wavelength of emission for CO2 lasers?

What is the classic wavelength of emission for CO2 lasers?

A CO2 laser provides a much lower electrical-to-optical conversion efficiency than ______ lasers.

A CO2 laser provides a much lower electrical-to-optical conversion efficiency than ______ lasers.

Match the types of lasers with their primary applications:

Match the types of lasers with their primary applications:

Which of the following is NOT a common use for CO2 lasers?

Which of the following is NOT a common use for CO2 lasers?

Lasers can only cut metal materials.

Lasers can only cut metal materials.

What is one future scope for laser cutting machines mentioned?

What is one future scope for laser cutting machines mentioned?

Flashcards

3D Printer Safety

3D Printer Safety

Following safety instructions avoids injury during 3D printer use.

Filament Installation

Filament Installation

Correctly inserting filament into the hotend for printing.

Temperature Parameter (3D Printer)

Temperature Parameter (3D Printer)

Adjusting temperature settings in a 3D printer for optimal print quality.

Voltage Selection (3D Printer)

Voltage Selection (3D Printer)

Signup and view all the flashcards

Bed Leveling (3D Printer)

Bed Leveling (3D Printer)

Signup and view all the flashcards

Component Assembly (3D Printer)

Component Assembly (3D Printer)

Signup and view all the flashcards

Software Parameters (3D Printer)

Software Parameters (3D Printer)

Signup and view all the flashcards

Filament Insertion Temperature

Filament Insertion Temperature

Signup and view all the flashcards

Leveling 3D printer

Leveling 3D printer

Signup and view all the flashcards

Nozzle Height Adjustment

Nozzle Height Adjustment

Signup and view all the flashcards

Cura Software

Cura Software

Signup and view all the flashcards

Loading 3D Model into Cura

Loading 3D Model into Cura

Signup and view all the flashcards

Model Manipulation in Cura

Model Manipulation in Cura

Signup and view all the flashcards

Lay Flat Option

Lay Flat Option

Signup and view all the flashcards

Clear Platform

Clear Platform

Signup and view all the flashcards

Machine Settings (Cura)

Machine Settings (Cura)

Signup and view all the flashcards

Model Scaling

Model Scaling

Signup and view all the flashcards

View Mode (Cura)

View Mode (Cura)

Signup and view all the flashcards

G-Code File Naming

G-Code File Naming

Signup and view all the flashcards

Wire Diameter

Wire Diameter

Signup and view all the flashcards

Nozzle Size

Nozzle Size

Signup and view all the flashcards

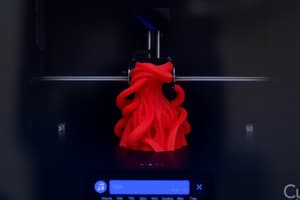

Printing Speed

Printing Speed

Signup and view all the flashcards

Online Driver Installation

Online Driver Installation

Signup and view all the flashcards

Cura Online Printing

Cura Online Printing

Signup and view all the flashcards

Filament Sensor

Filament Sensor

Signup and view all the flashcards

Bent Filament Tip

Bent Filament Tip

Signup and view all the flashcards

Resume from Outage

Resume from Outage

Signup and view all the flashcards

Nozzle Temperature

Nozzle Temperature

Signup and view all the flashcards

Nozzle Clogging

Nozzle Clogging

Signup and view all the flashcards

Heat Bed Leveling

Heat Bed Leveling

Signup and view all the flashcards

Filament Flow

Filament Flow

Signup and view all the flashcards

Print Platform Cleanliness

Print Platform Cleanliness

Signup and view all the flashcards

Gaps on Top Layer

Gaps on Top Layer

Signup and view all the flashcards

Insufficient Layers

Insufficient Layers

Signup and view all the flashcards

Wire Drawing

Wire Drawing

Signup and view all the flashcards

Insufficient Withdrawal

Insufficient Withdrawal

Signup and view all the flashcards

Print Model Melting

Print Model Melting

Signup and view all the flashcards

Layer Shifting

Layer Shifting

Signup and view all the flashcards

Gaps Between Layers

Gaps Between Layers

Signup and view all the flashcards

Uneven Extrusion

Uneven Extrusion

Signup and view all the flashcards

Grinding Filament

Grinding Filament

Signup and view all the flashcards

Rough Surface Angle

Rough Surface Angle

Signup and view all the flashcards

Wrinkled Surface

Wrinkled Surface

Signup and view all the flashcards

Filament Extrusion Issues

Filament Extrusion Issues

Signup and view all the flashcards

Z-axis Not Straight

Z-axis Not Straight

Signup and view all the flashcards

Print Temperature Too High

Print Temperature Too High

Signup and view all the flashcards

Insufficient Cooling

Insufficient Cooling

Signup and view all the flashcards

Printing Speed Too Fast

Printing Speed Too Fast

Signup and view all the flashcards

Laser

Laser

Signup and view all the flashcards

CNC Laser

CNC Laser

Signup and view all the flashcards

CO₂ Laser

CO₂ Laser

Signup and view all the flashcards

Nd Laser

Nd Laser

Signup and view all the flashcards

Nd:YAG Laser

Nd:YAG Laser

Signup and view all the flashcards

Laser Marking

Laser Marking

Signup and view all the flashcards

Laser Annealing

Laser Annealing

Signup and view all the flashcards

Laser Welding

Laser Welding

Signup and view all the flashcards

Study Notes

3D Printer (Chapter 1)

-

Safety Instructions:

- High temperatures are generated during operation, avoid touching the machine parts or extruded materials.

- Allow printed objects to cool before handling.

- Keep the printer in a well-ventilated area.

- Be cautious with scrapers, do not point towards hands.

- Protect the printer from water and rain.

- Maintain operating temperature and humidity (8°C - 40°C, 20%-50%).

- Use protective eyewear during cleaning/sanding of printed models.

- Turn off the printer in emergency situations and consult for professional advice.

- Do not modify or upgrade firmware unless necessary.

- Never leave the printer unattended during operation.

-

Contents of Manual:

- Part List 1

- Product Overview 2

- Menu Directory 3

- Assembly Instructions 6

- Leveling Instructions 13

- Cura Instructions 18

- Online Printing 26

- Offline Printing 29

- Change Filament 30

- Resume From Outage 31

- Trouble Shooting 33

-

Technical Specifications:

- Printing Parameters:

- Printing Volume: 300 x 300 x 400 (mm)

- Layer Resolution: 0.05 - 0.3 mm

- Positioning Accuracy: X/Y 0.0125 mm, Z 0.002 mm

- Extruder Quantity: Single

- Nozzle Diameter: 0.5/0.4/0.3/0.2 mm

- Printing Speed: 10 - 180 mm/s (60 mm/s recommended)

- Movement Speed: 100 mm/s

- Printing Materials: PLA, ABS, HIPS, WOOD, PETG, etc.

- Temperature Parameters:

- Ambient Operating Temperature: 8°C - 40°C

- Operational Extruder Temperature: up to 260°C

- Operational Print Bed Temperature: up to 110°C

- Software Parameters:

- Slicing Software: Cura, etc.

- Software Input Format: STL, .OBJ, .DAE, .AMF, etc.

- Software Output Format: G-Code

- Connectivity: SD card, USB (Expert users only)

- Electrical:

- Power Input: 110V/220V AC, 50/60Hz

- Power Output: 24V 15A 360W

- Physical Parameters:

- Machine Size: 482mm x 551mm x 656mm

- Net Weight: 12.8kg

- Printing Parameters:

Assembly Instructions

- Detailed step-by-step instructions for assembling the various components are provided (Fig. 1-10).

- Includes diagrams for visual guidance.

Leveling Instructions

- Detailed instructions and diagrams on how to level the printing platform before printing ,(Fig. 13-16)

- Explains how to adjust the nuts for proper surface-nozzle distance (typically about 0.1-0.2 mm).

Cura Instructions

-

Installation: Steps on installing and configuring the Cura slicing software.

- Provides guidance on selecting appropriate machine profiles and settings.

-

File Loading and Manipulation: Explains how to import 3D models, (Fig. 26-27) scale, reposition, and rotate 3D models within Cura for proper printing orientation.

-

Saving G-code: Instructions on saving the generated G-code files

Online and Offline Printing Instructions

- Offline Printing: Explanation of printing via SD card.

- Online Printing: Details on how to connect the 3D printer to a PC through USB, and use printer control software.

Troubleshooting

- General Problems: A list of common problems and their potential solutions is provided.

- Hot End Clogged: Troubleshooting steps for a clogged hot end.

- Not Extruding: Troubleshooting steps for extruder problems.

- Filling virtual filament: Troubleshooting steps for issues with filling virtual filament.

- Printing Model Issues: Solutions for various print quality issues (e.g. gaps, stripes, rough surfaces).

- Vibration: Solutions for issues with the 3D printer vibrating excessively during operation.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.