Podcast

Questions and Answers

What is the fundamental process behind 3D printing?

What is the fundamental process behind 3D printing?

- Melting materials and molding them into shape.

- Carving materials from a solid block.

- Pressing materials into a desired form.

- Depositing materials in layers based on a digital model. (correct)

What year was the first 3D printer invented?

What year was the first 3D printer invented?

- 1983 (correct)

- 2003

- 1993

- 1973

What term is often used interchangeably with '3D printing,' especially in industrial settings?

What term is often used interchangeably with '3D printing,' especially in industrial settings?

- Geometrical prototyping

- Subtractive manufacturing

- Additive manufacturing (correct)

- Formwork construction

In what decade did experimental applications of 3D printing begin in the construction industry?

In what decade did experimental applications of 3D printing begin in the construction industry?

Which of the following is a common application of 3D printing in construction?

Which of the following is a common application of 3D printing in construction?

What material is commonly used in concrete 3D printing?

What material is commonly used in concrete 3D printing?

What type of printer was the first 3D printer developed by Charles Hull?

What type of printer was the first 3D printer developed by Charles Hull?

What is the primary function of "Selective solidification (SLA)" in 3D printing?

What is the primary function of "Selective solidification (SLA)" in 3D printing?

Which of the following is a key advantage of 3D printing in manufacturing, as described in the principles?

Which of the following is a key advantage of 3D printing in manufacturing, as described in the principles?

According to the principles of 3D printing, what statement is correct?

According to the principles of 3D printing, what statement is correct?

How does 3D printing contribute to waste reduction in construction?

How does 3D printing contribute to waste reduction in construction?

What is a significant safety benefit of incorporating 3D printing into construction?

What is a significant safety benefit of incorporating 3D printing into construction?

What is a notable benefit of 3D printing concerning design in construction?

What is a notable benefit of 3D printing concerning design in construction?

According to Marco Vonk, what percentage of time and labor can be saved using 3D printing?

According to Marco Vonk, what percentage of time and labor can be saved using 3D printing?

What is identified as a major impediment to the widespread use of 3D printing in construction?

What is identified as a major impediment to the widespread use of 3D printing in construction?

What are the factors that amplify weather issues with 3D printing?

What are the factors that amplify weather issues with 3D printing?

What is one potential regulatory challenge associated with using 3D printers in construction?

What is one potential regulatory challenge associated with using 3D printers in construction?

What does the 'Extrusion based Single Deposition Nozzle Concrete Printer' resemble?

What does the 'Extrusion based Single Deposition Nozzle Concrete Printer' resemble?

What is the construction method based on extruding cement-based concrete against a trowel?

What is the construction method based on extruding cement-based concrete against a trowel?

In powder-bed-based 3D concrete printing, what is applied to the powder layer by a print-head?

In powder-bed-based 3D concrete printing, what is applied to the powder layer by a print-head?

Which 3D printing method is recommended for creating art objects that require meticulous detail?

Which 3D printing method is recommended for creating art objects that require meticulous detail?

What material is the first 3D printed pedestrian bridge in the world printed in?

What material is the first 3D printed pedestrian bridge in the world printed in?

What is the name of the 3D-printed research habitat that will provide long duration habitation for astronauts on missions to Mars?

What is the name of the 3D-printed research habitat that will provide long duration habitation for astronauts on missions to Mars?

According to Tvasta, what is the waste created in 3D technology vs conventional building methods?

According to Tvasta, what is the waste created in 3D technology vs conventional building methods?

Which company has created a 400-square-foot-home being built from scratch in just 24 hours?

Which company has created a 400-square-foot-home being built from scratch in just 24 hours?

What material does TECLA use for 3D printing buildings?

What material does TECLA use for 3D printing buildings?

What is a key environmental benefit of using soil in 3D construction?

What is a key environmental benefit of using soil in 3D construction?

What is a limitation of using powder-bed fusion for 3D concrete printing?

What is a limitation of using powder-bed fusion for 3D concrete printing?

Which factor poses a significant challenge to the structural integrity of 3D-printed buildings?

Which factor poses a significant challenge to the structural integrity of 3D-printed buildings?

Which aspect of software poses a challenge for 3D printing in construction?

Which aspect of software poses a challenge for 3D printing in construction?

Why must constant human oversight be maintained with 3D printing?

Why must constant human oversight be maintained with 3D printing?

What is the role of local materials in future construction with 3D printing?

What is the role of local materials in future construction with 3D printing?

What is required regarding regulations for 3D printing to make a mark in the construction sector?

What is required regarding regulations for 3D printing to make a mark in the construction sector?

What key property of lunar geopolymer mix is improved by adding urea, according to research on lunar construction materials?

What key property of lunar geopolymer mix is improved by adding urea, according to research on lunar construction materials?

What is a critical consideration for using basalt fiber extracted from Martian rocks in 3D printing construction on Mars?

What is a critical consideration for using basalt fiber extracted from Martian rocks in 3D printing construction on Mars?

Which obstacle is the most difficult to overcome for a team looking to colonize the planet?

Which obstacle is the most difficult to overcome for a team looking to colonize the planet?

Several factors contribute to the interior, organic shaping of 3D-printed unit form. Which of the answers is correct?

Several factors contribute to the interior, organic shaping of 3D-printed unit form. Which of the answers is correct?

What unique adaptation allows the houses in Valentino Gareri Atelier's Sunflower Village to maximize clean energy?

What unique adaptation allows the houses in Valentino Gareri Atelier's Sunflower Village to maximize clean energy?

How do each of the houses reduce the need for automated air-conditioning?

How do each of the houses reduce the need for automated air-conditioning?

The 'Sunflower' represents what kind of new model?

The 'Sunflower' represents what kind of new model?

According to the principles of 3D printing, how does printing a complex object compare to printing a simple one?

According to the principles of 3D printing, how does printing a complex object compare to printing a simple one?

According to the principles of 3D printing, what advantage does it offer concerning the geometries that can be printed?

According to the principles of 3D printing, what advantage does it offer concerning the geometries that can be printed?

According to the principles of 3D printing, what is a notable benefit regarding assembly?

According to the principles of 3D printing, what is a notable benefit regarding assembly?

According to the principles of 3D printing, what is a characteristic of its design space?

According to the principles of 3D printing, what is a characteristic of its design space?

What is a characteristic of the skill required to use 3D printers, according to the principles of 3D printing?

What is a characteristic of the skill required to use 3D printers, according to the principles of 3D printing?

According to the principles of 3D printing, how does a 3D printer's manufacturing capacity compare to that of a traditional machine?

According to the principles of 3D printing, how does a 3D printer's manufacturing capacity compare to that of a traditional machine?

According to the principles of 3D printing, which statement accurately describes its waste by-product?

According to the principles of 3D printing, which statement accurately describes its waste by-product?

According to the principles of 3D printing, what capability does it offer regarding materials?

According to the principles of 3D printing, what capability does it offer regarding materials?

According to the principles of 3D printing, what is a characteristic of 3D printing when replicating a physical object?

According to the principles of 3D printing, what is a characteristic of 3D printing when replicating a physical object?

According to Construction Dive, what is the expected trend for worldwide construction waste by 2025?

According to Construction Dive, what is the expected trend for worldwide construction waste by 2025?

What is a primary reason 3D printing significantly reduces construction waste?

What is a primary reason 3D printing significantly reduces construction waste?

How does the integration of 3D printing affect the number of worker injuries and fatalities on construction sites?

How does the integration of 3D printing affect the number of worker injuries and fatalities on construction sites?

What construction technology does the 'Extrusion based Single Deposition Nozzle Concrete Printer' resemble?

What construction technology does the 'Extrusion based Single Deposition Nozzle Concrete Printer' resemble?

Which factor is a significant logistical challenge for the construction industry in adopting 3D printing?

Which factor is a significant logistical challenge for the construction industry in adopting 3D printing?

What is a key aspect of labor that presents a challenge for the construction industry in adopting 3D printing?

What is a key aspect of labor that presents a challenge for the construction industry in adopting 3D printing?

How does the design process in 3D-printed unit construction influence the final urban structure?

How does the design process in 3D-printed unit construction influence the final urban structure?

In the context of constructing lunar shelters using 3D printing, what unique binding agent is considered in conjunction with lunar geopolymer mix and why?

In the context of constructing lunar shelters using 3D printing, what unique binding agent is considered in conjunction with lunar geopolymer mix and why?

In Valentino Gareri Atelier's Sunflower Village, how do the houses achieve optimal solar energy accumulation?

In Valentino Gareri Atelier's Sunflower Village, how do the houses achieve optimal solar energy accumulation?

What is an innovative design element in Valentino Gareri Atelier's Sunflower Village that facilitates natural ventilation and reduces the reliance on mechanical air conditioning?

What is an innovative design element in Valentino Gareri Atelier's Sunflower Village that facilitates natural ventilation and reduces the reliance on mechanical air conditioning?

Why is the 'Sunflower' village considered a new model of residential village?

Why is the 'Sunflower' village considered a new model of residential village?

Flashcards

What is 3D printing?

What is 3D printing?

3D printing is a process to create objects, depositing materials based on a digital model.

3D printing

3D printing

Also known as 'additive manufacturing'. Used when referring to its use within a manufacturing setting, and many individuals will use both phrases interchangeably

Who created the first 3D printer?

Who created the first 3D printer?

The first 3D printer was developed by Charles Hull in 1984

Application of 3D printing

Application of 3D printing

Signup and view all the flashcards

Concrete Printing

Concrete Printing

Signup and view all the flashcards

What printer does concrete printing use?

What printer does concrete printing use?

Signup and view all the flashcards

Manufacturing complexity is free

Manufacturing complexity is free

Signup and view all the flashcards

Variety is free

Variety is free

Signup and view all the flashcards

No assembly required

No assembly required

Signup and view all the flashcards

Zero lead time

Zero lead time

Signup and view all the flashcards

Zero skill manufacturing

Zero skill manufacturing

Signup and view all the flashcards

Benefits of 3D printing

Benefits of 3D printing

Signup and view all the flashcards

What is the total worldwide construction waste?

What is the total worldwide construction waste?

Signup and view all the flashcards

Reduce human error

Reduce human error

Signup and view all the flashcards

Design freedom

Design freedom

Signup and view all the flashcards

Speed

Speed

Signup and view all the flashcards

Challenges of 3D printing

Challenges of 3D printing

Signup and view all the flashcards

Quality control challenge

Quality control challenge

Signup and view all the flashcards

Labor shortage

Labor shortage

Signup and view all the flashcards

Regulation challenge

Regulation challenge

Signup and view all the flashcards

3D concrete printing

3D concrete printing

Signup and view all the flashcards

Additive manufacturing

Additive manufacturing

Signup and view all the flashcards

Contour crafting

Contour crafting

Signup and view all the flashcards

Y-BOX Pavilion

Y-BOX Pavilion

Signup and view all the flashcards

Where is the world's 3D bridge located at?

Where is the world's 3D bridge located at?

Signup and view all the flashcards

World’s First 3D Printed Bridge

World’s First 3D Printed Bridge

Signup and view all the flashcards

What are the dimensions of the 3D printed bridge?

What are the dimensions of the 3D printed bridge?

Signup and view all the flashcards

Bjarke Ingels Group

Bjarke Ingels Group

Signup and view all the flashcards

Mars Science City

Mars Science City

Signup and view all the flashcards

Photovoltaic frameless tiles

Photovoltaic frameless tiles

Signup and view all the flashcards

3D printed residential village

3D printed residential village

Signup and view all the flashcards

Tvasta cost

Tvasta cost

Signup and view all the flashcards

What is the Apis Cor printing house?

What is the Apis Cor printing house?

Signup and view all the flashcards

What is WASP?

What is WASP?

Signup and view all the flashcards

What are WASP houses?

What are WASP houses?

Signup and view all the flashcards

What is the Tecla housing model?

What is the Tecla housing model?

Signup and view all the flashcards

3D printed roofing

3D printed roofing

Signup and view all the flashcards

Marsha prototype

Marsha prototype

Signup and view all the flashcards

Lunar geopolymer

Lunar geopolymer

Signup and view all the flashcards

Building the future with 3D printing

Building the future with 3D printing

Signup and view all the flashcards

Nature over concrete

Nature over concrete

Signup and view all the flashcards

Study Notes

What is 3D Printing

- 3D printing is a process where physical objects are created by depositing materials layer by layer, using a digital model.

- 3D printing processes require software, hardware, and materials.

- Charles W. invented the first 3D printer in 1983.

- 3D printing has become one of the fastest-growing technologies, evolving from complicated and expensive to commonly used in industrial practice.

- 3D printing is also known as 'additive manufacturing', especially in industrial settings, and the terms can be used interchangeably.

History of 3D Printing in Construction

- Charles Hull developed the first printer in 1984.

- Experimental application of 3D printing in the construction industry started in the early 1990s.

- Reproduction of historical building ornamental components is one application of 3D printing in construction.

- Spall damage repair on concrete roads is another application.

- NASA is interested in the potential of 3D construction in space.

Concrete Printing

- Typically uses high-performance concrete, allowing more geometrical control.

- Concrete printing uses SLA printers.

- Charles Hull developed SLA printers as the first 3D printer.

- "Selective solidification (SLA) makes a solid object from a vat of liquid by selectively applying energy to solidify the liquid a layer at a time"

10 Principles of 3D Printing

- Manufacturing complexity is free, meaning that printing complex objects doesn't require more time, money or skill than printing simple ones.

- Variety is free, making it possible to print different geometries with the same printer each time, unlike traditional factory machines that need recalibration for each new type of object.

- No assembly is required, because a traditional multi-parts object can be 3D printed in one shot, eliminating the assembly line to saves time and cost on labor, transportation, and making production more sustainable.

- Zero lead time enables local companies and individuals to print custom objects on-demand.

- Unlimited design space enables printers to create shapes that are nearly or actually impossible to create with traditional machines, and reaching into possibilities that could not exist in nature unassisted.

- Zero skill manufacturing means that calibrating a printer for an object requires less operator skills as the process is almost fully automated; this is useful for people in remote areas or under extreme circumstances.

- Compact, portable manufacturing means a 3D printer has more manufacturing capacity than traditional machines because items can be as big as the printer's volume, or even larger if the printhead is attached to a robotic arm.

- Less waste by-product means zero or next-to-zero waste occurs because it is an additive manufacturing technique.

- Infinite shades of materials, one of 3D printing's key goals, is the ability to print with multiple materials to new geometries and materials with new proprietary behaviors.

- Precise physical replication means an object can be scanned and printed identically, with any scientific, medical or design intervention can be made to the replica, leaving the original unaltered.

Benefits of 3D Printing for Construction

- 3D printing can help rebuild cities after natural disasters, provide shelter for homeless populations and build sustainable habitats.

Waste Reduction

- Worldwide construction waste is over 1 billion tons per year currently, and is expected to double by 2025, according to Construction Dive.

- 3D printing is an additive manufacturing process that can help solve construction waste issues because it only uses as much material as needed.

- Waste-zero building is likely through pairing with lean construction, prefabrication and other waste-reducing processes and building methods.

Reduce Human Error

-

5,000 workers are killed on the job each day.

- Worker injuries and fatalities would decrease when 3D printing is incorporated because construction becomes more programmable and automated.

Design Freedom

- It is possible to build complex designs that are usually unattainable, or too expensive or labor-intensive with conventional construction.

- This can allow for more innovation and creativity in commercial construction.

- 3D concrete printing enables the freedom to make any shape.

- It is possible to make angles, bend components, and make virtually any organic shape.

Speed

- 3D printing is able to build a house or building from the ground up in a few days.

- With conventional construction, it takes several months or even years to build a commercial building.

- 3D printing can save around 60% of the time on the jobsite and 80% in labor.

Challenges of 3D Printing in Construction

- Prohibitive Technology costs of large 3D printers, and logistics, are among a number of factors that may keep the technology from becoming mainstream.

- 3D printers are costly, not including the cost of materials or maintenance.

Quality Control

- Amplified Weather effects could increase and slow construction progress.

- The weather and environmental factors involved could make 3D printing a commercial bust.

- Quality in construction, already tricky, requires constant human monitoring which can be expensive.

Labor Shortage

- There aren't enough construction workers to meet the demand.

- 3D printing demands a more specific skill set from a small group of candidates.

- Construction labor shortages could make it more difficult to find qualified workers.

Regulations

- Regulation of 3D printing might not come to mind right away, and still hasn't fully impacted construction.

- There's liability related to using printers instead of humans to perform specific construction tasks, but this is currently uncertain.

- It is unlikely that 3D printing will mark too much of a difference in construction until regulations are clearly defined.

Challenges of 3D Printing in Construction

- Material: Printability, buildability, open time.

- Architecture and Design: Exclusion of building services, structural integrity, new design principles.

- 3D Printer: Directional dependency, Geometrical limitations

- Construction Management: Cost estimation, construction site setup, construction scheduling.

- Software Related: Cybersecurity, Interoperability, Suitability of the digital model for printing

- Stakeholders: Skepticism, less demand for workers, need for new skills

- Regulations and Liability: Lack of codes regulations, liability issues.

Sustainable elements of 3D construction

- Eco-friendly structure

- Geometric freedom

- Short supply chain

- Better productivity

- Constructability

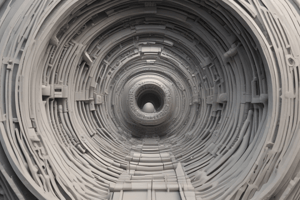

The emerging 3D Concrete Printing Technology

- It combines digital technologies and material sciences to allow free-form construction without formwork.

- This additive manufacturing technique involves fabricating a predesigned building element in 2D layers on top of each other, resulting in a 3D model.

- The concrete, which extrudes from a printing nozzle, doesn't require formwork or subsequent vibration.

3D Concrete Printing Processes

- Extrusion based Single Deposition Nozzle Concrete Printer, similar to fused deposition modeling.

- Powder deposition process where the "ink" is deposited on a powder bed.

Extrusion-Based 3D Concrete Printing

- It is similar to fused deposition modeling used in polymer and metal technologies.

- Contour crafting is an example of proprietary terminology, which is based on extruding a cement-based concrete with a trowel that allows a smooth finish through layering.

3D concrete printing - example

- The two-story villa printed by Huashang Tengda company.

- It is believed to be the first structure to be built entirely on-site, unlike others pieced together.

- Located in Tongzhou, a district of Beijing, the house was built in 45 days across an area of 400 m2 with two levels, and each of them is 3 meters high.

- The reinforced concrete walls are 0.25m thick and able to withstand an earthquake that measures eight on the Richter scale.

Powder-Bed-Based 3D Concrete Printing

- A thin layer of powder is spread over the powder bed surface first.

- Then, binder droplets are selectively applied by a print-head to bind powder particles to each other.

- Binders are deposited only in places that will be solid, and the rest is kept loose and removed later.

- D-shape 3D printing construction technology is used by this process.

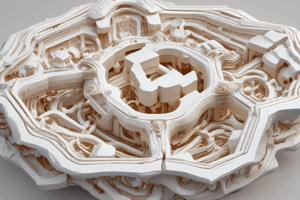

Y-BOX Pavilion

- Designed by architect Pitupong Chaowakul, from Supermachine Studio.

- The pavilion was created through a combination of powder bed and inkjet head 3D printing and 3D extrusion printing

- The pavilion took three months to 3D print.

- Used for creating art objects that require meticulous detail.

- 3D extrusion printing is for constructing structural building elements or even whole buildings.

- The design is unconventional, with six columns that twist upward in different styles, giving it a "21st C. Cave" feel reminiscent of natural stalagmites and a round geodesic lamp.

World's First 3D Printed Bridge in Spain

- The parametric design distributed material optimally and minimized waste via recycling in production.

- Maximum structural performance was allowed because the material only has to be used where it is needed.

- Complete freedom in terms of structural form was achieved by maintaining porosity and challenging traditional techniques of construction,

- The first 3D printed pedestrian bridge opened to the public on December 14 in Madrid, led by the Institute of Advanced Architecture of Catalonia (IAAC).

- The structure crossed a stream in Castilla-La Mancha Park in Alcobendas, Madrid.

- It is made of micro-reinforced concrete, and measures 12 meters in length and 1.75 meters wide.

NASA and ICON's 3D-Printed Research Habitats for Mars

- Bjarke Ingels Group has collaborated with NASA and ICON to create Mars Dune Alpha, a 3D-printed research habitat that long duration habitation for astronauts to Mars.

- The 1,700 sq.ft. structure is currently located at the Johnson Space Center in Houston, Texas, and was designed by the award-winning architecture firm, 3D printed by construction developers ICON.

- NASA has begun recruitment for the long-duration Mars mission analog study inside the 3D-printed habitat, to commence in Fall 2022.

- ICON has received funding from NASA to launch "Project Olympus", the research and development of a space-based construction system to support future exploration and missions on the Moon.

Mars Science Center

- Mars, the most habitable planet in our solar system after Earth, and proposals for the red planet explore humanity's ability to create new realms beyond earth.

- In 2017, a team from the Mohammed bin Rashid Space Center collaborated with BIG architectural office to develop a project that simulates Martian conditions on Earth, in order to research and test different building strategies to withstand Mars' heat and radiation.

- The project, Mars Science City, will utilize 3D printing and sand from the Emirati desert.

- Mars Science City will house food, energy, and water laboratories, landscaping to test farming and food security, and a museum to celebrate humanity's achievements in space and educate visitors.

- It will utilize one technique to construct Martian habitats, 3D printing with materials from the Emirates' deserts.

3D Printed Residential Village

- Valentino Gareri Atelier have joined forces with wellness consultant Steve Lastro of 6Sides and global real estate innovators Delos to create Sunflower Village, a humanistic and sociological approach to residential technology & community living.

- The proposed village includes 19 homes arranged in a sunflower composition to 'follow the sun'.

- Made by 3d- concrete-printing technology, the construction process of the units shape the final urban form.

- The houses are distributed around a communal area, with photovoltaic roofs shaped and angled towards the sun to receive clean energy.

- Each house is designed to be energy self-efficient, due to orientation and frameless photovolatic tiles on the angled roofs, which collect the clean energy, are stored in batteries, and used for the floor-heating system, air- conditioning, and for electric cars.

India's First 3D-Printed Home

- A standard 3D printer can produce a 2,000-sq ft home in less than a week, which is 1/8th of the total time spent today in erecting a functioning house.

- As per Tvasta, the cost of constructing a 3D printed house is approximately Rs 5 lakhs to Rs 5.5 lakhs, roughly 20% of the cost of a standard 2BHK apartment.

- Tvasta’s first structure is a single-storey house, a 600-sq ft unit, created in collaboration with Habitat for Humanity’s Terwilliger Center for Innovation in Shelter at the IIT-Madras campus.

- The house was built in just five days.

- This technology creates only 1/3rd of the waste generated using conventional building methods.

APIS COR Printed House in Russia

- A Russian company constructed a 400 sq ft home from scratch in just 24 hours in Moscow.

- The building cost $10,000, and built on site using a mobile 3D printer.

- The printed walls and foundations used a concrete mixture, with windows, fixtures, and furniture being added afterwards.

- A fresh coat of paint brought the final cost of the project to $10,134.

3D Printing Eco-Building

- It is building towards a more sustainable 3D Printing Architecture, replacing concrete with soil as a primary building material.

- Inspired by potter WASP, since 2012 WASP(World's Advanced Saving Project) have been developing viable construction processes based on the principles of circular economy and digital fabrication.

- On the market since 2021, WASP produces 3D-printed houses in the shortest possible time and in the most sustainable way with the first multi-printer Crane WASP system, the company's flagship of the construction line and the newco WASP On Site the company's benchmark in architecture.

TECLA

- A new circular housing model, created using entirely reusable, recyclable materials taken from the local terrain, is built using Crane WASP.

- TECLA will be the first house to be entirely 3D printed using locally sourced clay, a biodegradable and recyclable 'km 0 natural' material, which will effectively make the building zero-waste.

- It will adapt to multiple environments, will be suitable for self-production through the use of WASP's innovative Maker Economy Starter Kit, and limit industrial waste offer a unique sustainable model to boost the national and local economy,

- The scheme improves the wellbeing of communities and accelerates the construction process as the 3D printer will produce the entire structure once and for all.

Applications of 3D Printing in Construction

- Winsun, a Chinese company, invented the spray nozzle in 2005 and the first continuous 3D printer in 2008; in Dubai, Winsun created the first 3D-printed office.

- 3D Printhuset, a Danish company, constructed the first 3D-printed building in 2017 in Copenhagen.

- CyBe is a Dutch company that claims to have developed the first mobile 3D printer, able to print a full building on site; its machine can operate down to negative 35 °C.

3D Printed Roofing

- In undeveloped countries,engineers are creating cheaper roofing options for lower-income populations using 3D printing technology.

- The roofing is based on the look of terra cotta tiles made from recycled plastic, a less expensive, longer-lasting option.

- These 3D-printed roofing tiles come in two sizes, are interchangeable, interlocking, and can cover a 12 x 12-foot room without support.

Mix Local Materials and 3D Printing

- Since the surface of Mars is very inhospitable, utilizing what is available locally is important.

- If humans colonize further planets, then supplying spaceships with construction materials will be impossible.

- The Marsha prototype, developed by AI Space Factory, was the winning proposal in the “NASA Centennial Challenge" contest that can use 3D printing techniques a mixture of basalt fiber extracted from Martian rocks and renewable bioplastic processed from plants.

- The recyclable polymer composite outperformed concrete in NASA's strength, durability, and crushing tests.

- There is also research for shelters on the surface of the Moon, also printed in 3D with lunar concrete", which is mainly powdery soil known as lunar regolith found on the moon.

- The mixture coming out of a 3D printer proved to be stronger and maintained good workability by lunar geopolymer urea worked better plasticizers, while allowing reductions in the amount of water needed.

3D Printing - Sustainable material choice

- There is more environmentally sustainable alternatives to concrete being researched, especially a focus on soil itself, where the soil can harvested and planted without needing long distance transportation, reduces the carbon footprint and built-in energy costs.

Building the Future with 3D Printing

- It could provide affordable housing, disaster shelters, and sustainable construction.

- A key advantage is its lower construction costs due to the ease of calculating construction material, resulting in less waste, as well as their fast fabrication times compared to traditional structures.

- Californian-based Mighty Buildings prints a unit in just 24 hours.

- This speed could allow 3D printing to create emergency shelters in times of need, as well as increase access to housing as demand increases.

- Another sustainable advantage can provide that local and natural materials can be used as an alternative to concrete.

- Wasp and Mario Cucinella Architects have been testing alternatives to concrete in 3D printing.

3D Printing by TECLA

- Their projects, such as TECLA in Italy with clay, is paving the way for sustainable 3D printing.

- It is also important being able to utilize local resources for projects that are literally out of this world, such as by NASA partner ICON to create the first simulated Mars habitat

- If humans settle on Mars, it will be essential to fabricate structures from local materials.

- And 3D construction could be the answer to how they could do it.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.