Podcast

Questions and Answers

What is one key advantage of 3D printing related to design capability?

What is one key advantage of 3D printing related to design capability?

- It allows for the use of standard manufacturing templates.

- It reduces the design cycle time to less than an hour.

- It permits complex designs that are difficult with traditional methods. (correct)

- It eliminates the need for any prototypes.

Which limitation of 3D printing is primarily related to the materials used?

Which limitation of 3D printing is primarily related to the materials used?

- The initial cost for 3D printers is low.

- Finishing processes are often unnecessary.

- Part quality and precision are inconsistent.

- The selection of available materials is still limited. (correct)

How does 3D printing contribute to reduced material waste?

How does 3D printing contribute to reduced material waste?

- It only prints the necessary volumes required for each section. (correct)

- It uses recycled materials exclusively.

- It eliminates the need for any excess materials.

- It allows for printing in bulk to save materials.

What is a significant future trend in the field of 3D printing?

What is a significant future trend in the field of 3D printing?

Which of the following is NOT a common limitation of 3D printing?

Which of the following is NOT a common limitation of 3D printing?

What is the primary advantage of using Stereolithography (SLA) in 3D printing?

What is the primary advantage of using Stereolithography (SLA) in 3D printing?

Which of the following 3D printing technologies is best suited for producing complex shapes with strong components?

Which of the following 3D printing technologies is best suited for producing complex shapes with strong components?

What are some materials that can be used in 3D printing?

What are some materials that can be used in 3D printing?

Which application of 3D printing focuses primarily on creating physical models for evaluation purposes?

Which application of 3D printing focuses primarily on creating physical models for evaluation purposes?

Which characteristic distinguishes Digital Light Processing (DLP) from Stereolithography (SLA)?

Which characteristic distinguishes Digital Light Processing (DLP) from Stereolithography (SLA)?

For which industry is 3D printing not commonly applied?

For which industry is 3D printing not commonly applied?

What is a primary limitation of Fused Deposition Modeling (FDM) compared to other 3D printing technologies?

What is a primary limitation of Fused Deposition Modeling (FDM) compared to other 3D printing technologies?

What is the significance of slicing a digital model in 3D printing?

What is the significance of slicing a digital model in 3D printing?

Flashcards

Customization in 3D printing

Customization in 3D printing

Creating custom items tailored to individual needs, unlike mass-produced products.

Design Flexibility in 3D Printing

Design Flexibility in 3D Printing

The ability to make complex designs that traditional manufacturing methods struggle with.

Decentralized Production in 3D Printing

Decentralized Production in 3D Printing

Producing parts exactly where they are needed, reducing transportation time and costs.

Material Limitations in 3D Printing

Material Limitations in 3D Printing

Signup and view all the flashcards

Post-Processing in 3D Printing

Post-Processing in 3D Printing

Signup and view all the flashcards

3D Printing

3D Printing

Signup and view all the flashcards

Additive Manufacturing

Additive Manufacturing

Signup and view all the flashcards

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM)

Signup and view all the flashcards

Stereolithography (SLA)

Stereolithography (SLA)

Signup and view all the flashcards

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS)

Signup and view all the flashcards

Digital Light Processing (DLP)

Digital Light Processing (DLP)

Signup and view all the flashcards

Material Jetting

Material Jetting

Signup and view all the flashcards

Prototyping

Prototyping

Signup and view all the flashcards

Study Notes

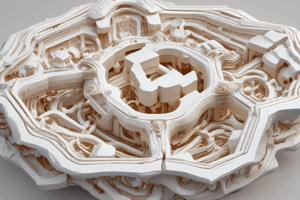

3D Printer Technology

- 3D printing, also known as additive manufacturing, creates three-dimensional objects from a digital file.

- It adds material layer by layer until the final object is formed.

- A variety of materials are used, including plastics, metals, ceramics, and composites.

- Material selection affects the final product's properties (strength, flexibility, temperature resistance, etc.).

- The process uses a digital model sliced into thin layers for the printer to build the object.

Types of 3D Printing Technologies

- Fused Deposition Modeling (FDM): A common method extruding a heated thermoplastic filament to build layers. It's relatively inexpensive and accessible, but resolution and material choices are limited.

- Stereolithography (SLA): Uses a UV laser to cure liquid resin layer by layer. Produces high-resolution, detailed parts, frequently used in prototyping and fine detail applications. Higher costs and potentially hazardous materials.

- Selective Laser Sintering (SLS): Uses a laser to sinter powdered materials (plastics, metals, or ceramics) into solid objects. Suitable for complex shapes and strong components, creating parts with high strength and precision.

- Digital Light Processing (DLP): Similar to SLA, using a digital light projector to cure the resin. Faster than SLA, frequently used for prototyping and rapid applications.

- Material Jetting: A process jetting small droplets of liquid materials for complex shapes, especially those with fine surface details.

Key Applications of 3D Printing

- Prototyping: Creates physical models for design review and testing, a quick and cost-effective method.

- Rapid Manufacturing: Produces parts for specific products on demand, allowing for customized designs.

- Medical Applications: 3D printed implants, prosthetics, and surgical guides tailored to each patient's needs.

- Aerospace: Creates lightweight components for planes and rockets with complex designs.

- Automotive: Quickly creates prototypes, tooling, or specialized parts for vehicles.

- Consumer Goods: Personalized products like home decor or functional accessories. This includes the possibility of mass customizing everyday objects.

Advantages of 3D Printing

- Design Flexibility: Allows for complex, intricate designs impossible or difficult with traditional manufacturing.

- Rapid Prototyping: Speeds up the design cycle, enables faster iteration and testing.

- Customization: Creates customized products tailored to specific needs.

- Reduced Material Waste: Only prints necessary volumes, decreasing waste.

- Decentralized Production: Manufacturers produce parts on-site at various locations; enables quicker response to demand and reduces transport costs.

Limitations of 3D Printing

- Material Selection: Material choices are limited compared to traditional techniques.

- Part Strength and Quality: Precision and strength of 3D printed components vary depending on method, material, and design.

- Cost: Initial setup costs for printers and materials are high.

- Potential for Post-Processing: Products may require additional finishing processes like sanding, painting, or support structure removal.

Future Trends in 3D Printing

- Continued advancements in 3D printing technologies will increase capabilities.

- Increased use of 3D printing for personalized and on-demand manufacturing.

- Integration of 3D printing with other technologies like AI and robotics will streamline and accelerate processes.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.