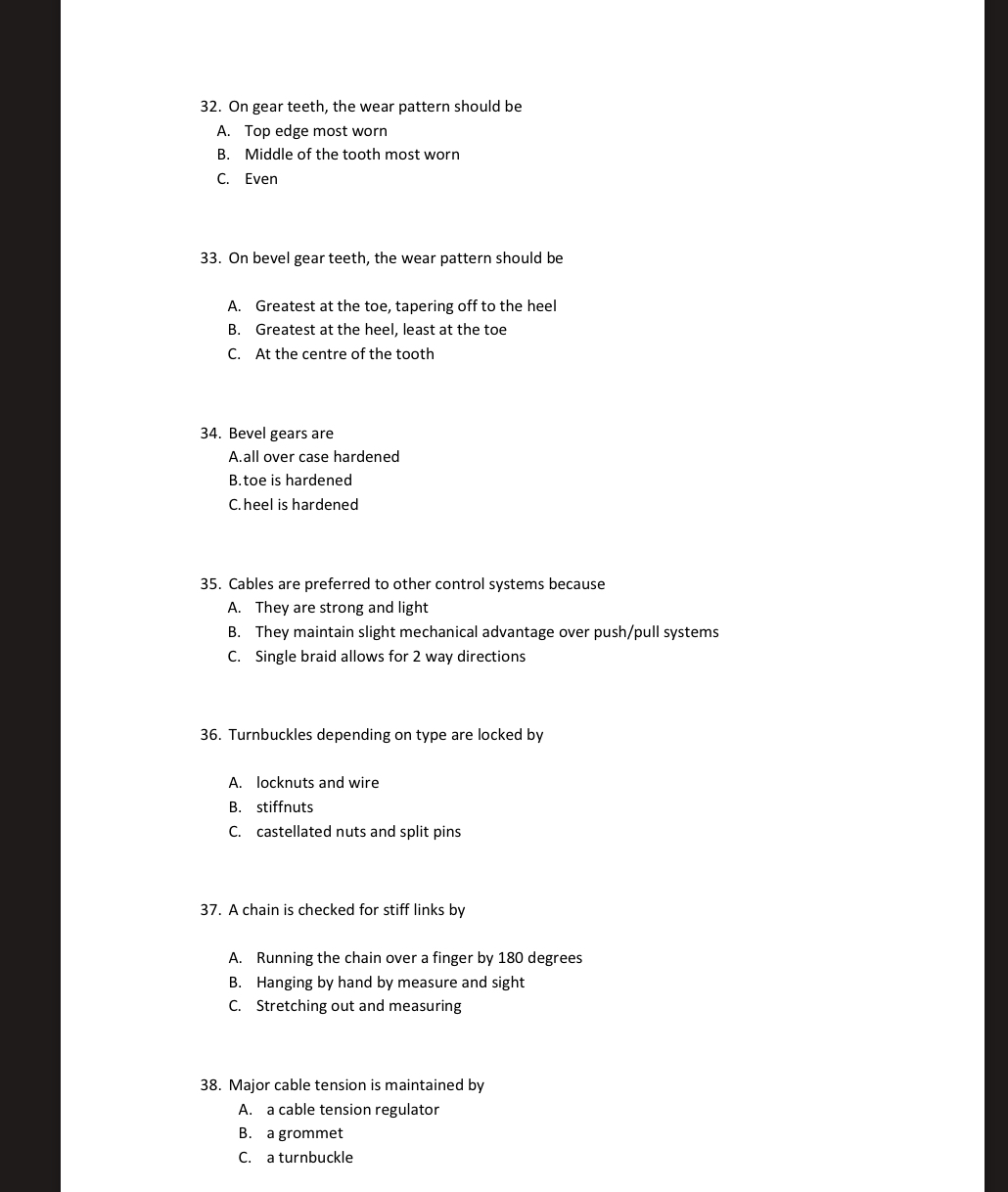

What should the wear pattern be on gear teeth? On bevel gear teeth? What are the strengths of cables over other control systems? How are turnbuckles locked by different types? How... What should the wear pattern be on gear teeth? On bevel gear teeth? What are the strengths of cables over other control systems? How are turnbuckles locked by different types? How is a chain checked for stiff links? What maintains major cable tension?

Understand the Problem

The question is asking about the proper wear patterns for gear teeth and related mechanical concepts, specifically focusing on the characteristics of bevel gears, cables, turnbuckles, and chain tensioning.

Answer

32. Even, 33. Centre of the tooth, 34. All over case hardened, 35. Strong and light, 36. Locknuts and wire, 37. Running over finger, 38. Cable tension regulator.

The final answers are: 32. Even, 33. At the centre of the tooth, 34. All over case hardened, 35. They are strong and light, 36. Locknuts and wire, 37. Running the chain over a finger by 180 degrees, 38. A cable tension regulator.

Answer for screen readers

The final answers are: 32. Even, 33. At the centre of the tooth, 34. All over case hardened, 35. They are strong and light, 36. Locknuts and wire, 37. Running the chain over a finger by 180 degrees, 38. A cable tension regulator.

More Information

On gear teeth, a uniform wear pattern is ideal to ensure even load distribution. Bevel gear teeth should wear at the center to maintain proper function. Cables are strong, light, and versatile, making them ideal for certain control systems. Turnbuckles are locked differently based on their type. A cable tension regulator is crucial for maintaining tension.

Tips

Ensure to check for uniform wear in gears to prevent imbalances and premature failure. Proper locking of turnbuckles is crucial for safety and reliability.

Sources

- Test 3272-6 har/mat (6.11) - Daypo - daypo.com

AI-generated content may contain errors. Please verify critical information